CHAPTER 4: ACCESSIBLE ROUTES

401.1 Scope.

The provisions of Chapter 4 shall apply where required by Chapter 2 or where referenced by a requirement in this document.

402.1 General.

Accessible routes shall comply with 402.

402.2 Components.

Accessible routes shall consist of one or more of the following components: walking surfaces with a running slope not steeper than 1:20, doorways, ramps, curb ramps excluding the flared sides, elevators, and platform lifts. All components of an accessible route shall comply with the applicable requirements of Chapter 4.

403.1 General.

Walking surfaces that are a part of an accessible route shall comply with 403.

403.2 Floor or Ground Surface.

Floor or ground surfaces shall comply with 302.

403.3 Slope.

The running slope of walking surfaces shall not be steeper than 1:20. The cross slope of walking surfaces shall not be steeper than 1:48.

403.4 Changes in Level.

Changes in level shall comply with 303.

403.5 Clearances.

Walking surfaces shall provide clearances complying with 403.5.

EXCEPTION: Within employee work areas, clearances on common use circulation paths shall be permitted to be decreased by work area equipment provided that the decrease is essential to the function of the work being performed.

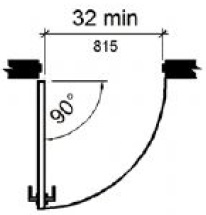

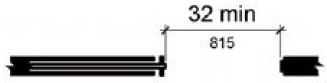

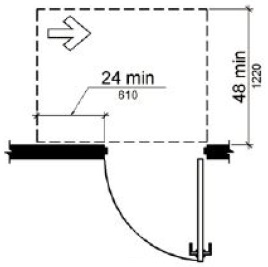

403.5.1 Clear Width.

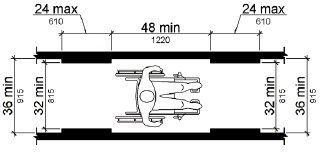

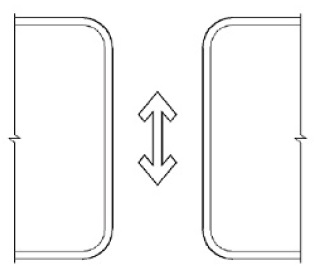

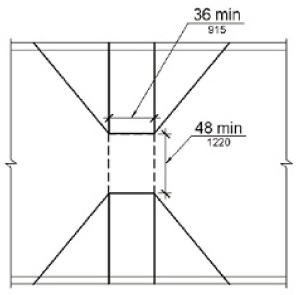

Except as provided in 403.5.2 and 403.5.3, the clear width of walking surfaces shall be 36 inches (915 mm) minimum.

EXCEPTION: The clear width shall be permitted to be reduced to 32 inches (815 mm) minimum for a length of 24 inches (610 mm) maximum provided that reduced width segments are separated by segments that are 48 inches (1220 mm) long minimum and 36 inches (915 mm) wide minimum.

Figure 403.5.1 Clear Width of an Accessible Route

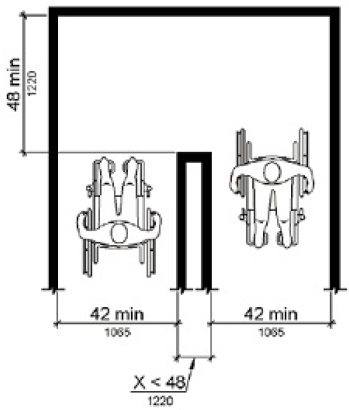

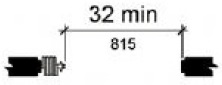

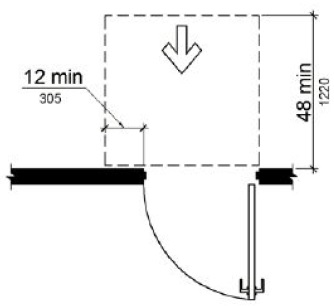

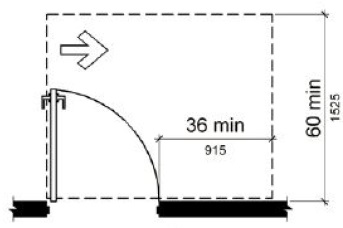

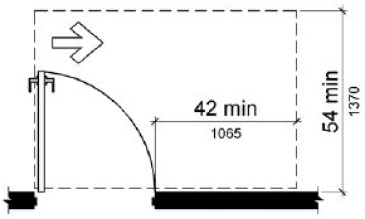

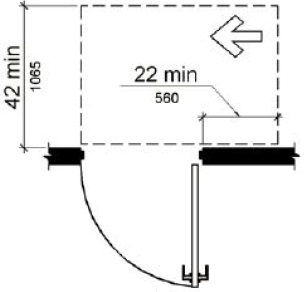

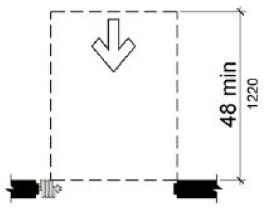

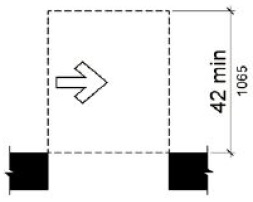

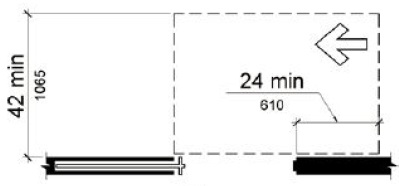

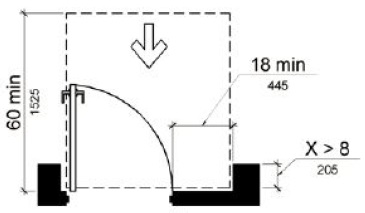

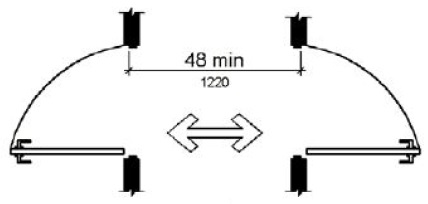

403.5.2 Clear Width at Turn.

Where the accessible route makes a 180 degree turn around an element which is less than 48 inches (1220 mm) wide, clear width shall be 42 inches (1065 mm) minimum approaching the turn, 48 inches (1220 mm) minimum at the turn and 42 inches (1065 mm) minimum leaving the turn.

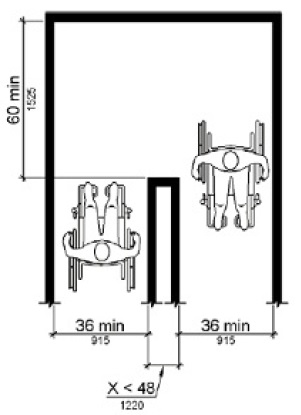

EXCEPTION: Where the clear width at the turn is 60 inches (1525 mm) minimum compliance with 403.5.2 shall not be required.

(a)

180 degree turn

(b)

180 degree turn

(Exception)

Figure 403.5.2 Clear Width at Turn

403.5.3 Passing Spaces.

An accessible route with a clear width less than 60 inches (1525 mm) shall provide passing spaces at intervals of 200 feet (61 m) maximum. Passing spaces shall be either: a space 60 inches (1525 mm) minimum by 60 inches (1525 mm) minimum; or, an intersection of two walking surfaces providing a T-shaped space complying with 304.3.2 where the base and arms of the T-shaped space extend 48 inches (1220 mm) minimum beyond the intersection.

403.6 Handrails.

Where handrails are provided along walking surfaces with running slopes not steeper than 1:20 they shall comply with 505.

Advisory 403.6 Handrails. Handrails provided in elevator cabs and platform lifts are not required to comply with the requirements for handrails on walking surfaces.

404.1 General.

Doors, doorways, and gates that are part of an accessible route shall comply with 404.

EXCEPTION: Doors, doorways, and gates designed to be operated only by security personnel shall not be required to comply with 404.2.7, 404.2.8, 404.2.9, 404.3.2 and 404.3.4 through 404.3.7.

Advisory 404.1 General Exception. Security personnel must have sole control of doors that are eligible for the Exception at 404.1. It would not be acceptable for security personnel to operate the doors for people with disabilities while allowing others to have independent access.

404.2 Manual Doors, Doorways, and Manual Gates.

Manual doors and doorways and manual gates intended for user passage shall comply with 404.2.

404.2.1 Revolving Doors, Gates, and Turnstiles.

Revolving doors, revolving gates, and turnstiles shall not be part of an accessible route.

404.2.2 Double-Leaf Doors and Gates.

At least one of the active leaves of doorways with two leaves shall comply with 404.2.3 and 404.2.4.

404.2.3 Clear Width.

Door openings shall provide a clear width of 32 inches (815 mm) minimum. Clear openings of doorways with swinging doors shall be measured between the face of the door and the stop, with the door open 90 degrees. Openings more than 24 inches (610 mm) deep shall provide a clear opening of 36 inches (915 mm) minimum. There shall be no projections into the required clear opening width lower than 34 inches (865 mm) above the finish floor or ground. Projections into the clear opening width between 34 inches (865 mm) and 80 inches (2030 mm) above the finish floor or ground shall not exceed 4 inches (100 mm).

EXCEPTIONS:

1. In alterations, a projection of 5/8 inch (16 mm) maximum into the required clear width shall be permitted for the latch side stop.

2. Door closers and door stops shall be permitted to be 78 inches (1980 mm) minimum above the finish floor or ground.

(a)

hinged door

(b)

sliding door

(c)

folding door

Figure 404.2.3 Clear Width of Doorways

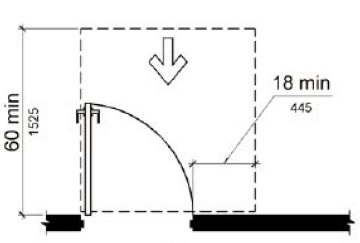

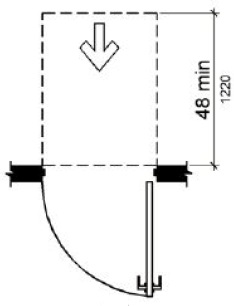

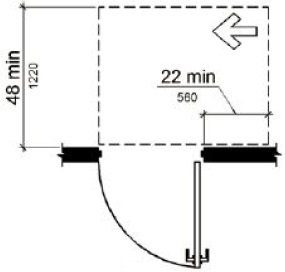

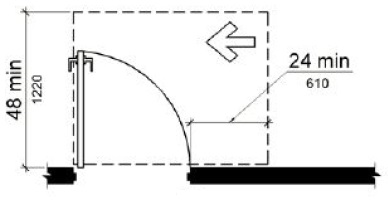

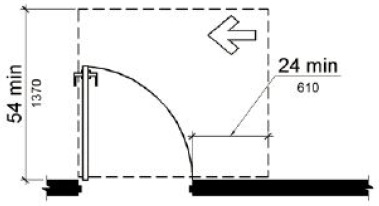

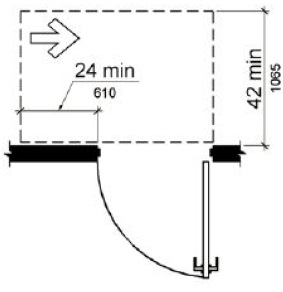

404.2.4 Maneuvering Clearances.

Minimum maneuvering clearances at doors and gates shall comply with 404.2.4. Maneuvering clearances shall extend the full width of the doorway and the required latch side or hinge side clearance.

EXCEPTION: Entry doors to hospital patient rooms shall not be required to provide the clearance beyond the latch side of the door.

404.2.4.1 Swinging Doors and Gates.

Swinging doors and gates shall have maneuvering clearances complying with Table 404.2.4.1.

| Type of Use | Minimum Maneuvering Clearance | ||

|---|---|---|---|

| Approach Direction | Door or Gate Side | Perpendicular to Doorway | Parallel to Doorway (beyond latch side unless noted) |

| From front | Pull | 60 inches (1525 mm) | 18 inches (455 mm) |

| From front | Push | 48 inches (1220 mm) | 0 inches (0 mm)1 |

| From hinge side | Pull | 60 inches (1525 mm) | 36 inches (915 mm) |

| From hinge side | Pull | 54 inches (1370 mm) | 42 inches (1065 mm) |

| From hinge side | Push | 42 inches (1065 mm)2 | 22 inches (560 mm)3 |

| From latch side | Pull | 48 inches (1220 mm)4 | 24 inches (610 mm) |

| From latch side | Push | 42 inches (1065 mm)4 | 24 inches (610 mm) |

1. Add 12 inches (305 mm) if closer and latch are provided.

2. Add 6 inches (150 mm) if closer and latch are provided.

3. Beyond hinge side.

4. Add 6 inches (150 mm) if closer is provided.

(a)

front approach, pull side

(b)

front approach, push side

(c)

front approach, push side, door provided with both closer and latch

(d)

hinge approach, pull side

(e)

hinge approach, pull side

(f)

hinge approach, push side

(g)

hinge approach, push side, door provided with both closer and latch

(h)

latch approach, pull side

(i)

latch approach, pull side, door provided with closer

(j)

latch approach, push side

(k)

latch approach, push side, door provided with closer

Figure 404.2.4.1 Maneuvering Clearances at Manual Swinging Doors and Gates

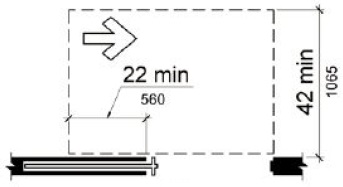

404.2.4.2 Doorways without Doors or Gates, Sliding Doors, and Folding Doors.

Doorways less than 36 inches (915 mm) wide without doors or gates, sliding doors, or folding doors shall have maneuvering clearances complying with Table 404.2.4.2.

Table 404.2.4.2 Maneuvering Clearances at Doorways without Doors or Gates, Manual Sliding Doors, and Manual Folding Doors

| Minimum Maneuvering Clearance | ||

| Approach Direction | Perpendicular to Doorway | Parallel to Doorway (beyond stop/latch side unless noted) |

| From Front | 48 inches (1220 mm) | 0 inches (0 mm) |

| From side1 | 42 inches (1065 mm) | 0 inches (0 mm) |

| From pocket/hinge side | 42 inches (1065 mm) | 22 inches (560 mm)2 |

| From stop/latch side | 42 inches (1065 mm) | 24 inches (610 mm) |

1. Doorway with no door only.

2. Beyond pocket/hinge side.

(a)

front approach

(b)

side approach

(c)

pocket or hinge approach

(d)

stop or latch approach

Figure 404.2.4.2 Maneuvering Clearances at Doorways Without Doors, Sliding Doors, Gates, and Folding Doors

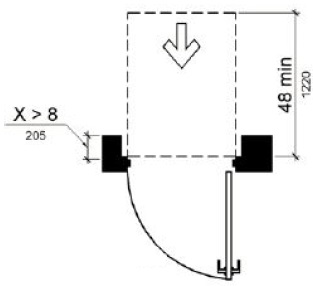

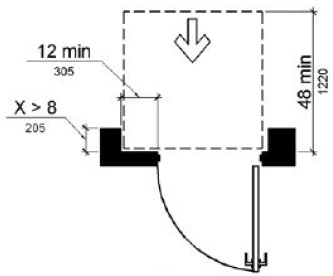

404.2.4.3 Recessed Doors and Gates.

Maneuvering clearances for forward approach shall be provided when any obstruction within 18 inches (455 mm) of the latch side of a doorway projects more than 8 inches (205 mm) beyond the face of the door, measured perpendicular to the face of the door or gate.

Advisory 404.2.4.3 Recessed Doors and Gates. A door can be recessed due to wall thickness or because of the placement of casework and other fixed elements adjacent to the doorway. This provision must be applied wherever doors are recessed.

(a)

pull side

(b)

push side

(c)

push side, door provided with both closer and latch

Figure 404.2.4.3 Maneuvering Clearances at Recessed Doors and Gates

404.2.4.4 Floor or Ground Surface.

Floor or ground surface within required maneuvering clearances shall comply with 302. Changes in level are not permitted.

EXCEPTIONS:

1. Slopes not steeper than 1:48 shall be permitted.

2. Changes in level at thresholds complying with 404.2.5 shall be permitted.

404.2.5 Thresholds.

Thresholds, if provided at doorways, shall be 1/2 inch (13 mm) high maximum. Raised thresholds and changes in level at doorways shall comply with 302 and 303.

EXCEPTION: Existing or altered thresholds 3/4 inch (19 mm) high maximum that have a beveled edge on each side with a slope not steeper than 1:2 shall not be required to comply with 404.2.5.

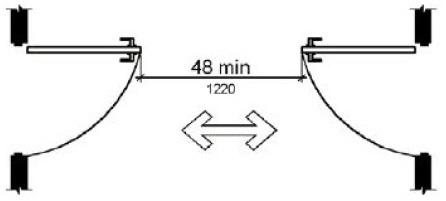

404.2.6 Doors in Series and Gates in Series.

The distance between two hinged or pivoted doors in series and gates in series shall be 48 inches (1220 mm) minimum plus the width of doors or gates swinging into the space.

(a)

(b)

(c)

Figure 404.2.6 Doors in Series and Gates in Series

404.2.7 Door and Gate Hardware.

Handles, pulls, latches, locks, and other operable parts on doors and gates shall comply with 309.4. Operable parts of such hardware shall be 34 inches (865 mm) minimum and 48 inches (1220 mm) maximum above the finish floor or ground. Where sliding doors are in the fully open position, operating hardware shall be exposed and usable from both sides.

EXCEPTIONS:

1. Existing locks shall be permitted in any location at existing glazed doors without stiles, existing overhead rolling doors or grilles, and similar existing doors or grilles that are designed with locks that are activated only at the top or bottom rail.

2. Access gates in barrier walls and fences protecting pools, spas, and hot tubs shall be permitted to have operable parts of the release of latch on self-latching devices at 54 inches (1370 mm) maximum above the finish floor or ground provided the self-latching devices are not also self-locking devices and operated by means of a key, electronic opener, or integral combination lock.

Advisory 404.2.7 Door and Gate Hardware. Door hardware that can be operated with a closed fist or a loose grip accommodates the greatest range of users. Hardware that requires simultaneous hand and finger movements require greater dexterity and coordination, and is not recommended.

404.2.8 Closing Speed.

Door and gate closing speed shall comply with 404.2.8.

404.2.8.1 Door Closers and Gate Closers.

Door closers and gate closers shall be adjusted so that from an open position of 90 degrees, the time required to move the door to a position of 12 degrees from the latch is 5 seconds minimum.

404.2.8.2 Spring Hinges.

Door and gate spring hinges shall be adjusted so that from the open position of 70 degrees, the door or gate shall move to the closed position in 1.5 seconds minimum.

404.2.9 Door and Gate Opening Force.

Fire doors shall have a minimum opening force allowable by the appropriate administrative authority. The force for pushing or pulling open a door or gate other than fire doors shall be as follows:

1. Interior hinged doors and gates: 5 pounds (22.2 N) maximum.

2. Sliding or folding doors: 5 pounds (22.2 N) maximum.

These forces do not apply to the force required to retract latch bolts or disengage other devices that hold the door or gate in a closed position.

Advisory 404.2.9 Door and Gate Opening Force. The maximum force pertains to the continuous application of force necessary to fully open a door, not the initial force needed to overcome the inertia of the door. It does not apply to the force required to retract bolts or to disengage other devices used to keep the door in a closed position.

404.2.10 Door and Gate Surfaces.

Swinging door and gate surfaces within 10 inches (255 mm) of the finish floor or ground measured vertically shall have a smooth surface on the push side extending the full width of the door or gate. Parts creating horizontal or vertical joints in these surfaces shall be within 1/16 inch (1.6 mm) of the same plane as the other. Cavities created by added kick plates shall be capped.

ETA Editor’s Note:

An existing door with a noncompliant kick plate is a safe harbored element for path of travel and barrier removal purposes but will have to comply when the door is replaced.

EXCEPTIONS:

1. Sliding doors shall not be required to comply with 404.2.10.

2. Tempered glass doors without stiles and having a bottom rail or shoe with the top leading edge tapered at 60 degrees minimum from the horizontal shall not be required to meet the 10 inch (255 mm) bottom smooth surface height requirement.

3. Doors and gates that do not extend to within 10 inches (255 mm) of the finish floor or ground shall not be required to comply with 404.2.10.

4. Existing doors and gates without smooth surfaces within 10 inches (255 mm) of the finish floor or ground shall not be required to provide smooth surfaces complying with 404.2.10 provided that if added kick plates are installed, cavities created by such kick plates are capped.

404.2.11 Vision Lights.

Doors, gates, and side lights adjacent to doors or gates, containing one or more glazing panels that permit viewing through the panels shall have the bottom of at least one glazed panel located 43 inches (1090 mm) maximum above the finish floor.

ETA Editor’s Note:

An existing door with a noncompliant vision light is a safe harbored element for path of travel and barrier removal purposes but will have to comply when the door is replaced.

EXCEPTION: Vision lights with the lowest part more than 66 inches (1675 mm) from the finish floor or ground shall not be required to comply with 404.2.11.

404.3 Automatic and Power-Assisted Doors and Gates.

Automatic doors and automatic gates shall comply with 404.3. Full-powered automatic doors shall comply with ANSI/BHMA A156.10 (incorporated by reference, see "Referenced Standards" in Chapter 1). Low-energy and power-assisted doors shall comply with ANSI/BHMA A156.19 (1997 or 2002 edition) (incorporated by reference, see "Referenced Standards" in Chapter 1).

404.3.1 Clear Width.

Doorways shall provide a clear opening of 32 inches (815 mm) minimum in power-on and power-off mode. The minimum clear width for automatic door systems in a doorway shall be based on the clear opening provided by all leaves in the open position.

404.3.2 Maneuvering Clearance.

Clearances at power-assisted doors and gates shall comply with 404.2.4. Clearances at automatic doors and gates without standby power and serving an accessible means of egress shall comply with 404.2.4.

EXCEPTION: Where automatic doors and gates remain open in the power-off condition, compliance with 404.2.4 shall not be required.

404.3.3 Thresholds.

Thresholds and changes in level at doorways shall comply with 404.2.5.

404.3.4 Doors in Series and Gates in Series.

Doors in series and gates in series shall comply with 404.2.6.

404.3.5 Controls.

Manually operated controls shall comply with 309. The clear floor space adjacent to the control shall be located beyond the arc of the door swing.

404.3.6 Break Out Opening.

Where doors and gates without standby power are a part of a means of egress, the clear break out opening at swinging or sliding doors and gates shall be 32 inches (815 mm) minimum when operated in emergency mode.

EXCEPTION: Where manual swinging doors and gates comply with 404.2 and serve the same means of egress compliance with 404.3.6 shall not be required.

404.3.7 Revolving Doors, Revolving Gates, and Turnstiles.

Revolving doors, revolving gates, and turnstiles shall not be part of an accessible route.

405.1 General.

Ramps on accessible routes shall comply with 405.

EXCEPTION: In assembly areas, aisle ramps adjacent to seating and not serving elements required to be on an accessible route shall not be required to comply with 405.

405.2 Slope.

Ramp runs shall have a running slope not steeper than 1:12.

EXCEPTION: In existing sites, buildings, and facilities, ramps shall be permitted to have running slopes steeper than 1:12 complying with Table 405.2 where such slopes are necessary due to space limitations.

Table 405.2 Maximum Ramp Slope and Rise for Existing Sites, Buildings, and Facilities

|

Slope¹ |

Maximum Rise |

|

Steeper than 1:10 but not steeper than 1:8 |

3 inches (75 mm) |

|

Steeper than 1:12 but not steeper than 1:10 |

6 inches (150 mm) |

1. A slope steeper than 1:8 is prohibited.

Advisory 405.2 Slope. To accommodate the widest range of users, provide ramps with the least possible running slope and, wherever possible, accompany ramps with stairs for use by those individuals for whom distance presents a greater barrier than steps, e.g., people with heart disease or limited stamina.

405.3 Cross Slope.

Cross slope of ramp runs shall not be steeper than 1:48.

Advisory 405.3 Cross Slope. Cross slope is the slope of the surface perpendicular to the direction of travel. Cross slope is measured the same way as slope is measured (i.e., the rise over the run).

405.4 Floor or Ground Surfaces.

Floor or ground surfaces of ramp runs shall comply with 302. Changes in level other than the running slope and cross slope are not permitted on ramp runs.

405.5 Clear Width.

The clear width of a ramp run and, where handrails are provided, the clear width between handrails shall be 36 inches (915 mm) minimum.

EXCEPTION: Within employee work areas, the required clear width of ramps that are a part of common use circulation paths shall be permitted to be decreased by work area equipment provided that the decrease is essential to the function of the work being performed.

405.6 Rise.

The rise for any ramp run shall be 30 inches (760 mm) maximum.

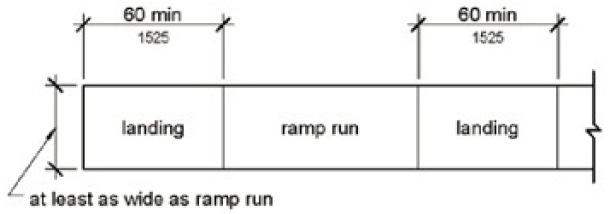

405.7 Landings.

Ramps shall have landings at the top and the bottom of each ramp run. Landings shall comply with 405.7.

Advisory 405.7 Landings. Ramps that do not have level landings at changes in direction can create a compound slope that will not meet the requirements of this document. Circular or curved ramps continually change direction. Curvilinear ramps with small radii also can create compound cross slopes and cannot, by their nature, meet the requirements for accessible routes. A level landing is needed at the accessible door to permit maneuvering and simultaneously door operation.

(a)

straight

(b)

change in direction

Figure 405.7 Ramp Landings

405.7.1 Slope.

Landings shall comply with 302. Changes in level are not permitted.

EXCEPTION: Slopes not steeper than 1:48 shall be permitted.

405.7.2 Width.

The landing clear width shall be at least as wide as the widest ramp run leading to the landing.

405.7.3 Length.

The landing clear length shall be 60 inches (1525 mm) long minimum.

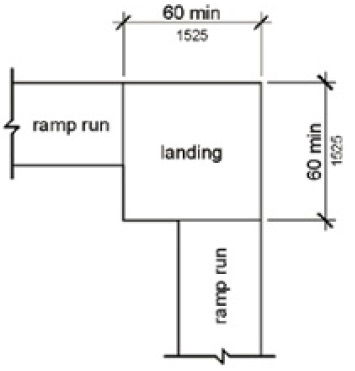

405.7.4 Change in Direction.

Ramps that change direction between runs at landings shall have a clear landing 60 inches (1525 mm) minimum by 60 inches (1525 mm) minimum.

405.7.5 Doorways.

Where doorways are located adjacent to a ramp landing, maneuvering clearances required by 404.2.4 and 404.3.2 shall be permitted to overlap the required landing area.

405.8 Handrails.

Ramp runs with a rise greater than 6 inches (150 mm) shall have handrails complying with 505.

EXCEPTION: Within employee work areas, handrails shall not be required where ramps that are part of common use circulation paths are designed to permit the installation of handrails complying with 505. Ramps not subject to the exception to 405.5 shall be designed to maintain a 36 inch (915 mm) minimum clear width when handrails are installed.

405.9 Edge Protection.

Edge protection complying with 405.9.1 or 405.9.2 shall be provided on each side of ramp runs and at each side of ramp landings.

EXCEPTIONS:

1. Edge protection shall not be required on ramps that are not required to have handrails and have sides complying with 406.3.

2. Edge protection shall not be required on the sides of ramp landings serving an adjoining ramp run or stairway.

3. Edge protection shall not be required on the sides of ramp landings having a vertical drop-off of ½ inch (13 mm) maximum within 10 inches (255 mm) horizontally of the minimum landing area specified in 405.7.

405.9.1 Extended Floor or Ground Surface.

The floor or ground surface of the ramp run or landing shall extend 12 inches (305 mm) minimum beyond the inside face of a handrail complying with 505.

Advisory 405.9.1 Extended Floor or Ground Surface. The extended surface prevents wheelchair casters and crutch tips from slipping off the ramp surface.

Figure 405.9.1 Extended Floor or Ground Surface Edge Protection

405.9.2 Curb or Barrier.

A curb or barrier shall be provided that prevents the passage of a 4 inch (100 mm) diameter sphere, where any portion of the sphere is within 4 inches (100 mm) of the finish floor or ground surface.

Figure 405.9.2 Curb or Barrier Edge Protection

405.10 Wet Conditions.

Landings subject to wet conditions shall be designed to prevent the accumulation of water.

406.1 General.

Curb ramps on accessible routes shall comply with 406, 405.2 through 405.5, and 405.10.

406.2 Counter Slope.

Counter slopes of adjoining gutters and road surfaces immediately adjacent to the curb ramp shall not be steeper than 1:20. The adjacent surfaces at transitions at curb ramps to walks, gutters, and streets shall be at the same level.

Figure 406.2 Counter Slope of Surfaces Adjacent to Curb Ramps

406.3 Sides of Curb Ramps.

Where provided, curb ramp flares shall not be steeper than 1:10.

Figure 406.3 Sides of Curb Ramps

406.4 Landings.

Landings shall be provided at the tops of curb ramps. The landing clear length shall be 36 inches (915 mm) minimum. The landing clear width shall be at least as wide as the curb ramp, excluding flared sides, leading to the landing.

EXCEPTION: In alterations, where there is no landing at the top of curb ramps, curb ramp flares shall be provided and shall not be steeper than 1:12.

ETA Editor’s Note:

Where insufficient space is available for a top landing, a parallel curb ramp as equivalent facilitation may be a better solution than flared sides.

Figure 406.4 Landings at the Top of Curb Ramps

406.5 Location.

Curb ramps and the flared sides of curb ramps shall be located so that they do not project into vehicular traffic lanes, parking spaces, or parking access aisles. Curb ramps at marked crossings shall be wholly contained within the markings, excluding any flared sides.

406.6 Diagonal Curb Ramps.

Diagonal or corner type curb ramps with returned curbs or other well-defined edges shall have the edges parallel to the direction of pedestrian flow. The bottom of diagonal curb ramps shall have a clear space 48 inches (1220 mm) minimum outside active traffic lanes of the roadway. Diagonal curb ramps provided at marked crossings shall provide the 48 inches (1220 mm) minimum clear space within the markings. Diagonal curb ramps with flared sides shall have a segment of curb 24 inches (610 mm) long minimum located on each side of the curb ramp and within the marked crossing.

Figure 406.6 Diagonal or Corner Type Curb Ramps

406.7 Islands.

Raised islands in crossings shall be cut through level with the street or have curb ramps at both sides. Each curb ramp shall have a level area 48 inches (1220 mm) long minimum by 36 inches (915 mm) wide minimum at the top of the curb ramp in the part of the island intersected by the crossings. Each 48 inch (1220 mm) minimum by 36 inch (915 mm) minimum area shall be oriented so that the 48 inch (1220 mm) minimum length is in the direction of the running slope of the curb ramp it serves. The 48 inch (1220 mm) minimum by 36 inch (915 mm) minimum areas and the accessible route shall be permitted to overlap.

(a)

cut through at island

(b)

curb ramp at island

Figure 406.7 Islands in Crossings

407.1 General.

Elevators shall comply with 407 and with ASME A17.1 (incorporated by reference, see "Referenced Standards" in Chapter 1). They shall be passenger elevators as classified by ASME A17.1. Elevator operation shall be automatic.

Advisory 407.1 General. The ADA and other Federal civil rights laws require that accessible features be maintained in working order so that they are accessible to and usable by those people they are intended to benefit. Building owners should note that the ASME Safety Code for Elevators and Escalators requires routine maintenance and inspections. Isolated or temporary interruptions in service due to maintenance or repairs may be unavoidable; however, failure to take prompt action to effect repairs could constitute a violation of Federal laws and these requirements.

407.2 Elevator Landing Requirements.

Elevator landings shall comply with 407.2.

407.2.1 Call Controls.

Where elevator call buttons or keypads are provided, they shall comply with 407.2.1 and 309.4. Call buttons shall be raised or flush.

EXCEPTION: Existing elevators shall be permitted to have recessed call buttons.

407.2.1.1 Height.

Call buttons and keypads shall be located within one of the reach ranges specified in 308, measured to the centerline of the highest operable part.

EXCEPTION: Existing call buttons and existing keypads shall be permitted to be located at 54 inches (1370 mm) maximum above the finish floor, measured to the centerline of the highest operable part.

407.2.1.2 Size.

Call buttons shall be 3/4 inch (19 mm) minimum in the smallest dimension.

EXCEPTION: Existing elevator call buttons shall not be required to comply with 407.2.1.2.

407.2.1.3 Clear Floor or Ground Space.

A clear floor or ground space complying with 305 shall be provided at call controls.

Advisory 407.2.1.3 Clear Floor or Ground Space. The clear floor or ground space required at elevator call buttons must remain free of obstructions including ashtrays, plants, and other decorative elements that prevent wheelchair users and others from reaching the call buttons. The height of the clear floor or ground space is considered to be a volume from the floor to 80 inches (2030 mm) above the floor. Recessed ashtrays should not be placed near elevator call buttons so that persons who are blind or visually impaired do not inadvertently contact them or their contents as they reach for the call buttons.

407.2.1.4 Location.

The call button that designates the up direction shall be located above the call button that designates the down direction.

EXCEPTION: Destination-oriented elevators shall not be required to comply with 407.2.1.4.

Advisory 407.2.1.4 Location, Exception. A destination-oriented elevator system provides lobby controls enabling passengers to select floor stops, lobby indicators designating which elevator to use, and a car indicator designating the floors at which the car will stop. Responding cars are programmed for maximum efficiency by reducing the number of stops any passenger experiences.

407.2.1.5 Signals.

Call buttons shall have visible signals to indicate when each call is registered and when each call is answered.

EXCEPTIONS:

1. Destination-oriented elevators shall not be required to comply with 407.2.1.5 provided that visible and audible signals complying with 407.2.2 indicating which elevator car to enter are provided.

2. Existing elevators shall not be required to comply with 407.2.1.5.

407.2.1.6 Keypads.

Where keypads are provided, keypads shall be in a standard telephone keypad arrangement and shall comply with 407.4.7.2.

407.2.2 Hall Signals.

Hall signals, including in-car signals, shall comply with 407.2.2.

407.2.2.1 Visible and Audible Signals.

A visible and audible signal shall be provided at each hoistway entrance to indicate which car is answering a call and the car's direction of travel. Where in-car signals are provided, they shall be visible from the floor area adjacent to the hall call buttons.

EXCEPTIONS:

1. Visible and audible signals shall not be required at each destination-oriented elevator where a visible and audible signal complying with 407.2.2 is provided indicating the elevator car designation information.

2. In existing elevators, a signal indicating the direction of car travel shall not be required.

407.2.2.2 Visible Signals.

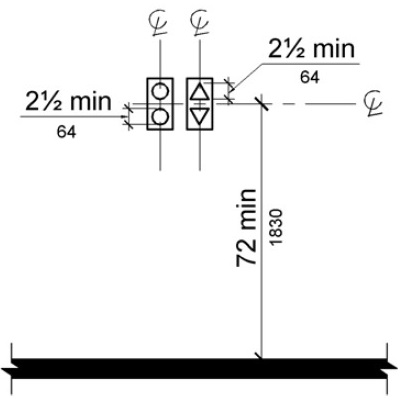

Visible signal fixtures shall be centered at 72 inches (1830 mm) minimum above the finish floor or ground. The visible signal elements shall be 2 1/2 inches (64 mm) minimum measured along the vertical centerline of the element. Signals shall be visible from the floor area adjacent to the hall call button.

EXCEPTIONS:

1. Destination-oriented elevators shall be permitted to have signals visible from the floor area adjacent to the hoistway entrance.

2. Existing elevators shall not be required to comply with 407.2.2.2.

Figure 407.2.2.2 Visible Hall Signals

407.2.2.3 Audible Signals.

Audible signals shall sound once for the up direction and twice for the down direction, or shall have verbal annunciators that indicate the direction of elevator car travel. Audible signals shall have a frequency of 1500 Hz maximum. Verbal annunciators shall have a frequency of 300 Hz minimum and 3000 Hz maximum. The audible signal and verbal annunciator shall be 10 dB minimum above ambient, but shall not exceed 80 dB, measured at the hall call button.

EXCEPTIONS:

1. Destination-oriented elevators shall not be required to comply with 407.2.2.3 provided that the audible tone and verbal announcement is the same as those given at the call button or call button keypad.

2. Existing elevators shall not be required to comply with the requirements for frequency and dB range of audible signals.

407.2.2.4 Differentiation.

Each destination-oriented elevator in a bank of elevators shall have audible and visible means for differentiation.

407.2.3 Hoistway Signs.

Signs at elevator hoistways shall comply with 407.2.3.

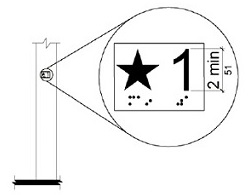

407.2.3.1 Floor Designation.

Floor designations complying with 703.2 and 703.4.1 shall be provided on both jambs of elevator hoistway entrances. Floor designations shall be provided in both tactile characters and braille. Tactile characters shall be 2 inches (51 mm) high minimum. A tactile star shall be provided on both jambs at the main entry level.

Figure 407.2.3.1 Floor Designations on Jambs of Elevator Hoistway Entrances

407.2.3.2 Car Designations.

Destination-oriented elevators shall provide tactile car identification complying with 703.2 on both jambs of the hoistway immediately below the floor designation. Car designations shall be provided in both tactile characters and braille. Tactile characters shall be 2 inches (51 mm) high minimum.

Figure 407.2.3.2 Car Designations on Jambs of Destination-Oriented Elevator Hoistway Entrances

407.3 Elevator Door Requirements.

Hoistway and car doors shall comply with 407.3.

407.3.1 Type.

Elevator doors shall be the horizontal sliding type. Car gates shall be prohibited.

407.3.2 Operation.

Elevator hoistway and car doors shall open and close automatically.

EXCEPTION: Existing manually operated hoistway swing doors shall be permitted provided that they comply with 404.2.3 and 404.2.9. Car door closing shall not be initiated until the hoistway door is closed.

407.3.3 Reopening Device.

Elevator doors shall be provided with a reopening device complying with 407.3.3 that shall stop and reopen a car door and hoistway door automatically if the door becomes obstructed by an object or person.

EXCEPTION: Existing elevators with manually operated doors shall not be required to comply with 407.3.3.

407.3.3.1 Height.

The device shall be activated by sensing an obstruction passing through the opening at 5 inches (125 mm) nominal and 29 inches (735 mm) nominal above the finish floor.

407.3.3.2 Contact.

The device shall not require physical contact to be activated, although contact is permitted to occur before the door reverses.

407.3.3.3 Duration.

Door reopening devices shall remain effective for 20 seconds minimum.

407.3.4 Door and Signal Timing.

The minimum acceptable time from notification that a car is answering a call or notification of the car assigned at the means for the entry of destination information until the doors of that car start to close shall be calculated from the following equation:

T = D/(1.5 ft/s) or T = D/(455 mm/s) = 5 seconds minimum where T equals the total time in seconds and D equals the distance (in feet or millimeters) from the point in the lobby or corridor 60 inches (1525 mm) directly in front of the farthest call button controlling that car to the centerline of its hoistway door.

EXCEPTIONS:

1. For cars with in-car lanterns, T shall be permitted to begin when the signal is visible from the point 60 inches (1525 mm) directly in front of the farthest hall call button and the audible signal is sounded.

2. Destination-oriented elevators shall not be required to comply with 407.3.4.

407.3.5 Door Delay.

Elevator doors shall remain fully open in response to a car call for 3 seconds minimum.

407.3.6 Width.

The width of elevator doors shall comply with Table 407.4.1.

EXCEPTION: In existing elevators, a power-operated car door complying with 404.2.3 shall be permitted.

407.4 Elevator Car Requirements.

Elevator cars shall comply with 407.4.

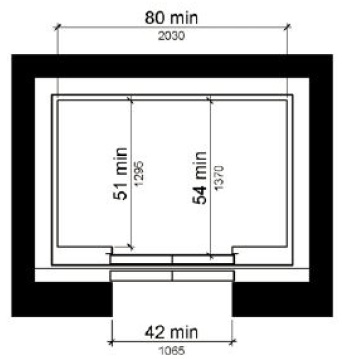

407.4.1 Car Dimensions.

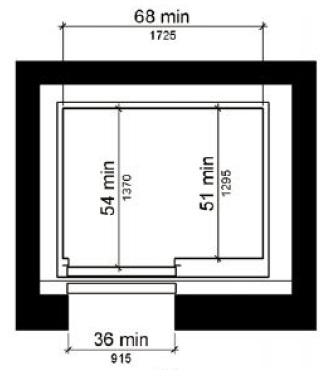

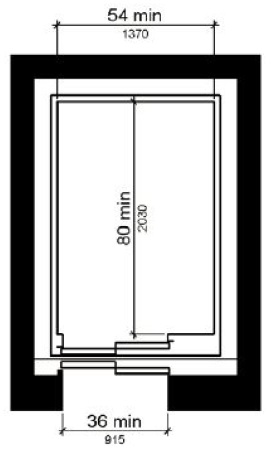

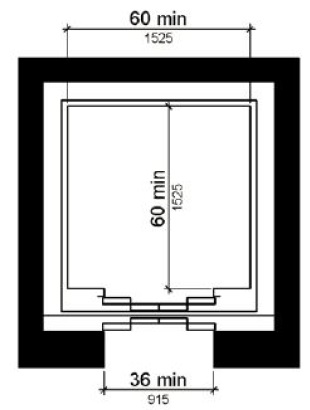

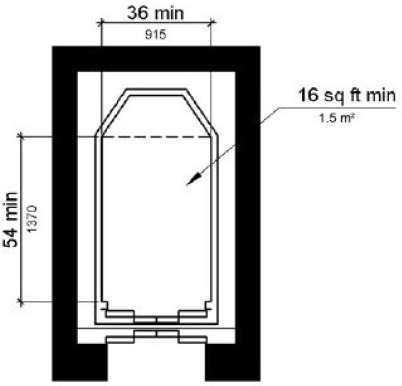

Inside dimensions of elevator cars and clear width of elevator doors shall comply with Table 407.4.1.

EXCEPTION: Existing elevator car configurations that provide a clear floor area of 16 square feet (1.5 m2) minimum and also provide an inside clear depth 54 inches (1370 mm) minimum and a clear width 36 inches (915 mm) minimum shall be permitted.

Table 407.4.1 Elevator Car Dimensions

|

Minimum Dimensions |

||||

|

Door Location |

Door Clear Width |

Inside Car, Side to Side |

Inside Car, Back Wall to Front Return |

Inside Car, Back Wall to Inside Face of Door |

|

Centered |

42 inches(1065 mm) |

80 inches(2030 mm) |

51 inches(1295 mm) |

54 inches(1370 mm) |

|

Side (off-centered) |

36 inches(915 mm)¹ |

68 inches(1725 mm) |

51 inches(1295 mm) |

54 inches(1370 mm) |

|

Any |

36 inches(915 mm)¹ |

54 inches(1370 mm) |

80 inches(2030 mm) |

80 inches(2030 mm) |

|

Any |

36 inches(915 mm)¹ |

60 inches(1525 mm)² |

60 inches(1525 mm)² |

60 inches(1525 mm)² |

1. A tolerance of minus 5/8 inch (16 mm) is permitted.

2. Other car configurations that provide a turning space complying with 304 with the door closed shall be permitted.

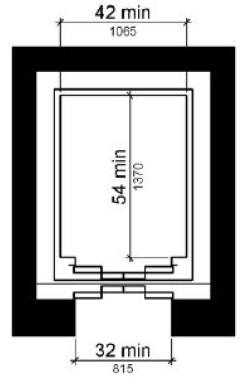

(a)

centered door

(b)

side (off-centered) door

(c)

any door location

(d)

any door location

(e)

Exception

existing elevator car configuration

Figure 407.4.1 Elevator Car Dimensions

407.4.2 Floor Surfaces.

Floor surfaces in elevator cars shall comply with 302 and 303.

407.4.3 Platform to Hoistway Clearance.

The clearance between the car platform sill and the edge of any hoistway landing shall be 1 1/4 inch (32 mm) maximum.

407.4.4 Leveling.

Each car shall be equipped with a self-leveling feature that will automatically bring and maintain the car at floor landings within a tolerance of 1/2 inch (13 mm) under rated loading to zero loading conditions.

407.4.5 Illumination.

The level of illumination at the car controls, platform, car threshold and car landing sill shall be 5 foot candles (54 lux) minimum.

407.4.6 Elevator Car Controls.

Where provided, elevator car controls shall comply with 407.4.6 and 309.4.

EXCEPTION: In existing elevators, where a new car operating panel complying with 407.4.6 is provided, existing car operating panels shall not be required to comply with 407.4.6.

407.4.6.1 Location.

Controls shall be located within one of the reach ranges specified in 308.

EXCEPTIONS:

1. Where the elevator panel serves more than 16 openings and a parallel approach is provided, buttons with floor designations shall be permitted to be 54 inches (1370 mm) maximum above the finish floor.

2. In existing elevators, car control buttons with floor designations shall be permitted to be located 54 inches (1370 mm) maximum above the finish floor where a parallel approach is provided.

407.4.6.2 Buttons.

Car control buttons with floor designations shall comply with 407.4.6.2 and shall be raised or flush.

EXCEPTION: In existing elevators, buttons shall be permitted to be recessed.

Buttons shall be 3/4 inch (19 mm) minimum in their smallest dimension.

Buttons shall be arranged with numbers in ascending order. When two or more columns of buttons are provided they shall read from left to right.

407.4.6.3 Keypads.

Car control keypads shall be in a standard telephone keypad arrangement and shall comply with 407.4.7.2.

407.4.6.4 Emergency Controls.

Emergency controls shall comply with 407.4.6.4.

Emergency control buttons shall have their centerlines 35 inches (890 mm) minimum above the finish floor.

Emergency controls, including the emergency alarm, shall be grouped at the bottom of the panel.

407.4.7 Designations and Indicators of Car Controls.

Designations and indicators of car controls shall comply with 407.4.7.

EXCEPTION: In existing elevators, where a new car operating panel complying with 407.4.7 is provided, existing car operating panels shall not be required to comply with 407.4.7.

407.4.7.1 Buttons.

Car control buttons shall comply with 407.4.7.1.

Control buttons shall be identified by tactile characters complying with 703.2.

Raised character and braille designations shall be placed immediately to the left of the control button to which the designations apply.

EXCEPTION: Where space on an existing car operating panel precludes tactile markings to the left of the controls, markings shall be placed as near to the control as possible.

The control button for the emergency stop, alarm, door open, door close, main entry floor, and phone, shall be identified with tactile symbols as shown in Table 407.4.7.1.3.

| Control Button | Tactile Symbol | Braille Message |

| Emergency Stop |  |

"ST"OP Three cells

|

| Alarm |  |

AL"AR"M Four cells

|

| Door Open |  |

OP"EN" Three cells

|

| Door Close |  |

CLOSE Five cells

|

| Main Entry Floor |  |

MA"IN" Three cells

|

| Phone |  |

PH"ONE" Four cells

|

407.4.7.1.4 Visible Indicators.

Buttons with floor designations shall be provided with visible indicators to show that a call has been registered. The visible indication shall extinguish when the car arrives at the designated floor.

407.4.7.2 Keypads.

Keypads shall be identified by characters complying with 703.5 and shall be centered on the corresponding keypad button. The number five key shall have a single raised dot. The dot shall be 0.118 inch (3 mm) to 0.120 inch (3.05 mm) base diameter and in other aspects comply with Table 703.3.1.

407.4.8 Car Position Indicators.

Audible and visible car position indicators shall be provided in elevator cars.

407.4.8.1 Visible Indicators.

Visible indicators shall comply with 407.4.8.1.

Characters shall be 1/2 inch (13 mm) high minimum.

Indicators shall be located above the car control panel or above the door.

As the car passes a floor and when a car stops at a floor served by the elevator, the corresponding character shall illuminate.

EXCEPTION: Destination-oriented elevators shall not be required to comply with 407.4.8.1.3 provided that the visible indicators extinguish when the call has been answered.

407.4.8.1.4 Destination Indicator.

In destination-oriented elevators, a display shall be provided in the car with visible indicators to show car destinations.

407.4.8.2 Audible Indicators.

Audible indicators shall comply with 407.4.8.2.

The signal shall be an automatic verbal annunciator which announces the floor at which the car is about to stop.

EXCEPTION: For elevators other than destination-oriented elevators that have a rated speed of 200 feet per minute (1 m/s) or less, a non-verbal audible signal with a frequency of 1500 Hz maximum which sounds as the car passes or is about to stop at a floor served by the elevator shall be permitted.

The verbal annunciator shall be 10 dB minimum above ambient, but shall not exceed 80 dB, measured at the annunciator.

The verbal annunciator shall have a frequency of 300 Hz minimum to 3000 Hz maximum.

407.4.9 Emergency Communication.

Emergency two-way communication systems shall comply with 308. Tactile symbols and characters shall be provided adjacent to the device and shall comply with 703.2.

408.1 General.

Limited-use/limited-application elevators shall comply with 408 and with ASME A17.1 (incorporated by reference, see "Referenced Standards" in Chapter 1). They shall be passenger elevators as classified by ASME A17.1. Elevator operation shall be automatic.

408.2 Elevator Landings.

Landings serving limited-use/limited-application elevators shall comply with 408.2.

408.2.1 Call Buttons.

Elevator call buttons and keypads shall comply with 407.2.1.

408.2.2 Hall Signals.

Hall signals shall comply with 407.2.2.

408.2.3 Hoistway Signs.

Signs at elevator hoistways shall comply with 407.2.3.1.

408.3 Elevator Doors.

Elevator hoistway doors shall comply with 408.3.

408.3.1 Sliding Doors.

Sliding hoistway and car doors shall comply with 407.3.1 through 407.3.3 and 408.4.1.

408.3.2 Swinging Doors.

Swinging hoistway doors shall open and close automatically and shall comply with 404, 407.3.2 and 408.3.2.

408.3.2.1 Power Operation.

Swinging doors shall be power-operated and shall comply with ANSI/BHMA A156.19 (1997 or 2002 edition) (incorporated by reference, see "Referenced Standards" in Chapter 1).

408.3.2.2 Duration.

Power-operated swinging doors shall remain open for 20 seconds minimum when activated.

408.4 Elevator Cars.

Elevator cars shall comply with 408.4.

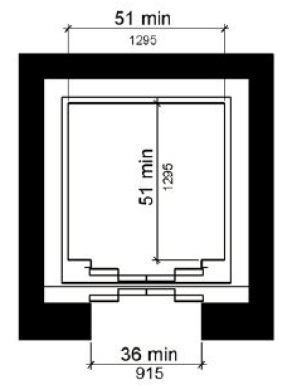

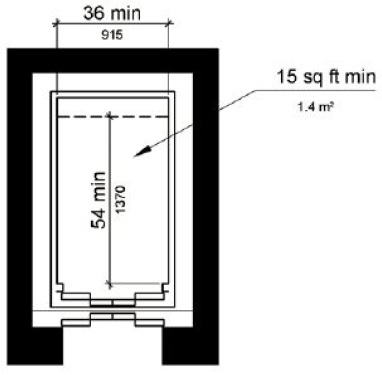

408.4.1 Car Dimensions and Doors.

Elevator cars shall provide a clear width 42 inches (1065 mm) minimum and a clear depth 54 inches (1370 mm) minimum. Car doors shall be positioned at the narrow ends of cars and shall provide 32 inches (815 mm) minimum clear width.

EXCEPTIONS:

1. Cars that provide a clear width 51 inches (1295 mm) minimum shall be permitted to provide a clear depth 51 inches (1295 mm) minimum provided that car doors provide a clear opening 36 inches (915 mm) wide minimum.

2. Existing elevator cars shall be permitted to provide a clear width 36 inches (915 mm) minimum, clear depth 54 inches (1370 mm) minimum, and a net clear platform area 15 square feet (1.4 m²) minimum.

(a)

new construction

(b)

Exception 1

(c)

Exception 2

Figure 408.4.1 Limited-Use/Limited-Application (LULA) Elevator Car Dimensions

408.4.2 Floor Surfaces.

Floor surfaces in elevator cars shall comply with 302 and 303.

408.4.3 Platform to Hoistway Clearance.

The platform to hoistway clearance shall comply with 407.4.3.

408.4.4 Leveling.

Elevator car leveling shall comply with 407.4.4.

408.4.5 Illumination.

Elevator car illumination shall comply with 407.4.5.

408.4.6 Car Controls.

Elevator car controls shall comply with 407.4.6. Control panels shall be centered on a side wall.

408.4.7 Designations and Indicators of Car Controls.

Designations and indicators of car controls shall comply with 407.4.7.

408.4.8 Emergency Communications.

Car emergency signaling devices complying with 407.4.9 shall be provided.

409.1 General.

Private residence elevators that are provided within a residential dwelling unit required to provide mobility features complying with 809.2 through 809.4 shall comply with 409 and with ASME A17.1 (incorporated by reference, see "Referenced Standards" in Chapter 1). They shall be passenger elevators as classified by ASME A17.1. Elevator operation shall be automatic.

409.2 Call Buttons.

Call buttons shall be 3/4 inch (19 mm) minimum in the smallest dimension and shall comply with 309.

409.3 Elevator Doors.

Hoistway doors, car doors, and car gates shall comply with 409.3 and 404.

EXCEPTION: Doors shall not be required to comply with the maneuvering clearance requirements in 404.2.4.1 for approaches to the push side of swinging doors.

409.3.1 Power Operation.

Elevator car and hoistway doors and gates shall be power operated and shall comply with ANSI/BHMA A156.19 (1997 or 2002 edition) (incorporated by reference, see "Referenced Standards" in Chapter 1). Power operated doors and gates shall remain open for 20 seconds minimum when activated.

EXCEPTION: In elevator cars with more than one opening, hoistway doors and gates shall be permitted to be of the manual-open, self-close type.

409.3.2 Location.

Elevator car doors or gates shall be positioned at the narrow end of the clear floor spaces required by 409.4.1.

409.4 Elevator Cars.

Private residence elevator cars shall comply with 409.4.

409.4.1 Inside Dimensions of Elevator Cars.

Elevator cars shall provide a clear floor space of 36 inches (915 mm) minimum by 48 inches (1220 mm) minimum and shall comply with 305.

409.4.2 Floor Surfaces.

Floor surfaces in elevator cars shall comply with 302 and 303.

409.4.3 Platform to Hoistway Clearance.

The clearance between the car platform and the edge of any landing sill shall be 1 1/2 inch (38 mm) maximum.

409.4.4 Leveling.

Each car shall automatically stop at a floor landing within a of 1/2 inch (13 mm) under rated loading to zero loading conditions.

409.4.5 Illumination Levels.

Elevator car illumination shall comply with 407.4.5.

409.4.6 Car Controls.

Elevator car control buttons shall comply with 409.4.6, 309.3, 309.4, and shall be raised or flush.

409.4.6.1 Size.

Control buttons shall be 3/4 inch (19 mm) minimum in their smallest dimension.

409.4.6.2 Location.

Control panels shall be on a side wall, 12 inches (305 mm) minimum from any adjacent wall.

Figure 409.6.2 [sic] Location of Private Residence Elevator Control Panel

409.4.7 Emergency Communications.

Emergency two-way communication systems shall comply with 409.4.7.

409.4.7.1 Type.

A telephone and emergency signal device shall be provided in the car.

409.4.7.2 Operable Parts.

The telephone and emergency signaling device shall comply with 309.3 and 309.4.

409.4.7.3 Compartment.

If the telephone or device is in a closed compartment, the compartment door hardware shall comply with 309.

409.4.7.4 Cord.

The telephone cord shall be 29 inches (735 mm) long minimum.

410.1 General.

Platform lifts shall comply with ASME A18.1 (1999 edition or 2003 edition) (incorporated by reference, see "Referenced Standards" in Chapter 1). Platform lifts shall not be attendant-operated and shall provide unassisted entry and exit from the lift.

Advisory 410.1 General. Inclined stairway chairlifts and inclined and vertical platform lifts are available for short-distance vertical transportation. Because an accessible route requires an 80 inch (2030 mm) vertical clearance, care should be taken in selecting lifts as they may not be equally suitable for use by people using wheelchairs and people standing. If a lift does not provide 80 inch (2030 mm) vertical clearance, it cannot be considered part of an accessible route in new construction.

The ADA and other Federal civil rights laws require that accessible features be maintained in working order so that they are accessible to and usable by those people they are intended to benefit. Building owners are reminded that the ASME A18 Safety Standard for Platform Lifts and Stairway Chairlifts requires routine maintenance and inspections. Isolated or temporary interruptions in service due to maintenance or repairs may be unavoidable; however, failure to take prompt action to effect repairs could constitute a violation of Federal laws and these requirements.

410.2 Floor Surfaces.

Floor surfaces in platform lifts shall comply with 302 and 303.

410.3 Clear Floor Space.

Clear floor space in platform lifts shall comply with 305.

410.4 Platform to Runway Clearance.

The clearance between the platform sill and the edge of any runway landing shall be 1 inch (32 mm) maximum.

410.5 Operable Parts.

Controls for platform lifts shall comply with 309.

410.6 Doors and Gates.

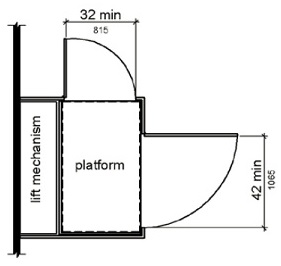

Platform lifts shall have low-energy power-operated doors or gates complying with 404.3. Doors shall remain open for 20 seconds minimum. End doors and gates shall provide a clear width 32 inches (815 mm) minimum. Side doors and gates shall provide a clear width 42 inches (1065 mm) minimum.

EXCEPTION: Platform lifts serving two landings maximum and having doors or gates on opposite sides shall be permitted to have self-closing manual doors or gates.

Figure 410.6 Platform Lift Doors and Gates

User Comments/Questions

Add Comment/Question