Installation and Serviceability Results: Governor Dodge State Park, Wisconsin

Theodore L. Laufenberg

Abstract

Trails made with wood chips are difficult for those who use mobility aids because the surface is soft, uneven, and shifting. This report describes the development of a concept for stabilizing engineered wood fiber (EWF) to improve wheelchair and walker accessibility for outdoor recreational trails where traditional paving would be costly and would detract from the natural aesthetics. The applicability and field performance of two binder-EWF systems previously developed for an outdoor playground were tested on a beach path and two bridle trails. The stabilized EWF (SEWF) system enhanced accessibility and should reduce erosion and maintenance costs for trail systems. Overall, the two systems performed well on the beach path but were not adequate for the bridle paths. Cost estimates and step-by-step instructions are provided for installing SEWF.

Keywords: wood, fiber, surfacing, accessibility, walkways, paths, ADA, composite, polyurethane, playground, durability, installation, cushioning

Acknowledgments

We gratefully acknowledge Bill Botten, U.S. Architectural and Transportation Compliance Board, for guidance in initiating Phase III of the development of the stabilized engineered wood fiber (EWF) concept, and Ted Illjes and Bob Zeager of Zeager Bros. Inc., Middletown, Pennsylvania, for performing the impact tests.

Zeager Bros. Inc. and Beneficial Designs, Inc. (Minden, Nevada), provided the apparatus for the impact test and the rotational penetrometer, as well as training in their use. Thanks to Zeager Bros. Inc. for the donation of EWF and Midwest Industrial Supply (Canton, Ohio) for the donation of Soil-Sement.

We are grateful to the Wisconsin Department of Natural Resources for offering park areas and trails for this study. In particular, we appreciate the guidance and support of Anthonette Gilpatrick, ADA Coordinator; Kathy Gruentzel, Park Manager; and the staff of Governor Dodge State Park for installing and monitoring the trail and beachwalk sites. Special thanks to Jane and Steve Schmieding, Carl Syftestad, Lloyd Currier, Nancy Keen, Vicki Herian, Mary Collet, and other members of the FPL staff, for their support of this effort.

Introduction

Wood chip surfaces on trails create difficulties for those who use mobility aids, such as wheelchairs and walkers, due to their softness, shifting, and uneven surface. This report is part of the third phase of research in pursuit of an accessible stable and smooth surface based on wood fiber. The study originally targeted the use of engineered wood fiber (EWF) (ASTM 2004) for playgrounds. In Phase I, processing techniques and material properties were evaluated in small benchtop and full-depth laboratory tests (Laufenberg and others 2003). Phase II involved further development of the best Phase I system in 6-month outdoor field testing (Laufenberg and Winandy 2003).

In Phase III of this project, we investigated the applicability and field performance of the two best candidate resin/EWF systems. The previous phases had shown that our new resin/EWF systems can enhance mobility as related to the Americans With Disabilities Act (ADA) and can perform in an outdoor environment. This report describes the development of a concept for stabilizing EWF to improve wheelchair and walker accessibility for outdoor recreational trails where traditional paving would be costly and would detract from the natural aesthetics. In this portion of the Phase III study, we installed our two most promising EWF stabilizing binders on a walkway across a sandy beach extending down to the water's edge. This surfacing material concept was to mix a binder with EWF to create a stiff (firm) and scuff-resistant (stable) composite. Stabilized EWF (SEWF) is a system that has enhanced accessibility and should reduce erosion and maintenance costs for trail systems.

Background

The initial research effort included a variety of resin (e.g., latex, silicone, and polyurethane) binders and various types of EWF. We chose adhesive binders for their inert and non-toxic nature in the environment and the retention of a natural look for the surface. Consideration was given to the need to add material or patch the surfaces after major damage. Use of a trail surface for 3 to 5 years was considered adequate time for the binder to fulfill its function. These adhesive systems have not been previously used in this application with EWF, therefore there is no experience with their functioning for that extended period. The preliminary evaluation included laboratory testing of energy absorption and surface firmness and stability on trial surfaces in 0.5- by 0.5-m (18- by 18-in.) plywood boxes; the surfaces had a uniform depth of 0.3 m (12 in.). Seven systems were identified as having reasonable performance and thence recommended for Phase II outdoor field evaluations.

Phase II research focused on outdoor evaluation of the binder and fiber options identified as minimally acceptable and promising in the Phase I evaluations. The Phase II work studied field durability and looked at changes in performance by quantifying the impact and accessibility of these novel surfaces after field exposure. This series included seven surface treatments, and a control surface, installed in a series of outdoor test beds in Madison, Wisconsin, to gather field experience on long-term performance and durability. The binders evaluated were (a) synthetic latex emulsion, (b) a low molecular weight silicone, and (c) foaming and non-foaming resilient polyurethane. Systems were evaluated over a 6-month period, from April to October 2002.

Tests were performed at regular intervals to provide a quantitative measure of accessibility. The results indicate that latex and polyurethane stabilizers consistently met the requirements for accessibility on playgrounds (Laufenberg and Winandy 2003). The foaming polyurethane formulation produced a hard brittle shell that became even harder with exposure/age and would increase the injury rate for falls on the surface. The silicone system did not maintain its integrity adequately during the rain/dry cycles in this outdoor test.

Monitoring of the Phase II test plot continued for 2 years after the initial 6-month evaluation reported by Laufenberg and Winandy (2003). In those 2 years, the synthetic latex emulsion and the non-foaming polyurethane continued to performed acceptably. As anticipated, the foaming polyurethane system continued to harden with exposure, rendering it unsuitable for meeting the impact absorption requirements for playground surfaces.

Objectives

The original development work, though targeted toward playground improvements, was eventually seen as a potential improvement for trail surfacing. Following the preliminary field trials, professionals involved in recreational surface development encouraged us to investigate the concept for trails. For trails, the primary emphasis was accessibility and natural aesthetics, and impact performance was a secondary characteristic. However, many processing and handling issues for playgrounds were also considerations for trail construction and use. Several such issues were considered. This study explores the use of the resin/EWF system as a surfacing material for accessible outdoor recreation trails.

Acceptable Trail Surfacing Requirements

Current trail design considerations include quantity of traffic and type of use, such as walking and wheelchair use, biking, horse riding, and other allowed uses. Trail surfaces are currently considered accessible only if the surfacing material is firm, stable, and slip-resistant and the trail has the engineered attributes of adequate width, moderately short slopes, passing spaces, and appropriate signage. A traditional paving material such as asphalt and concrete may be appropriate, but this type of surface is expensive to construct, requires the use of heavy materials and equipment, and may detract from the aesthetics of the trail.

The Americans with Disabilities Act (ADA 1990) states that accessible surfaces shall be stable, firm, and slip-resistant. These three criteria have not been defined adequately within the ADA Accessibility Guidelines for quantitative measurement on any specific surface. Currently, the only objective method that is suitable for assessing the firmness and stability of playground surfacing systems is the rotational penetrometer (Axelson and Chesney 1999).

As when constructing trails with native soils, it is very desirable to drain water quickly away from the surface of a SEWF trail. This is critical in maintaining the stability of native soils and for reducing the biodeterioration potential of a wood fiber based surface. Keeping water off the surface also maintains adequate friction on the stabilized EWF during sub-freezing temperatures. The rotational penetrometer, a portable measurement device that simulates a wheelchair caster negotiating the test surface, was used to assess the level of accessibility.

We also needed to consider several practical aspects for processing the SEWF material and maintaining a safe work environment. Based on our experience in field applications, stabilizing binders needed to be applied on site or mixed with the EWF no longer than 1 h prior to placement on the ground surface. The practical considerations were (a) cure/set time prior to surface use, (b) range of EWF moisture and temperature conditions acceptable for use, (c) emission of fumes or odors, workable exotherms, and toxic or other chemical release/concerns from the binder/ EWF mixture, and (d) deleterious effects of SEWF on trail users.

Trail Study Sites

An Access Board solicitation for potential playground study sites yielded numerous responses for trail work as well. An accessibility coordinator for the Wisconsin State Parks offered us an opportunity not far from the Forest Products Laboratory, at Governor Dodge State Park in Dodgeville, Wisconsin--to extend an accessible beach path and to attempt to stabilize two short sections of a severely eroded bridle path.

Beach Path

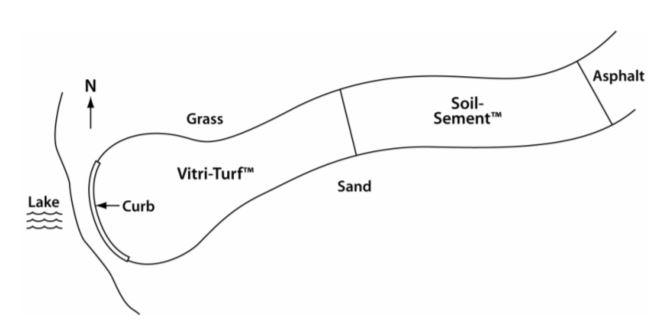

Our prototype test location for the SEWF concept on trails was an accessible beach path to Cox Hollow Lake. The existing path was 1.2-m- (4-ft-) wide blacktop asphalt extending 50 m (165 ft) from accessible parking to the beginning of the sand beach, 30 m (100 ft) from the water. Our task was to provide accessibility over the sand to the water, retaining the aesthetic quality of the area (National Center on Accessibility 2003).

Discussions with the park staff provided insight to the usage of the beach path. The desire was for park users to be able to maneuver a wheelchair directly to the water's edge, where they could access the beach and a boat landing (Fig. 1). Another consideration was the proximity of the path to the beach volleyball area. The SEWF surfaces were originally developed for use as impact-sensitive playground surfaces. Thus, their impact behavior was considered much more forgiving than that of an asphalt path.

Layout of the path across the beach was sloped so that the edge of the path would not hold water. Park personnel were concerned that sand would wash or get kicked over the path surface, which would decrease accessibility and increase maintenance requirements. Slope along the upper edge was a minimum of 1%. Nearer the waterline the slope of the path increased to a maximum of approximately 5% for the final few meters (feet). The amount of waterline fluctuation was considered minimal at this beach because of the proximity of water control structures.

Figure 1-Schematic plan of Governor Dodge State Park Cox Hollow beach path site (not to scale).

We first lowered and leveled the existing sand surface to a depth of 0.06 m (2.4 in.) (Fig. 2). Any stones and vegetation near the waterline were removed. Within 1.5 m (5 ft) (horizontal distance) of the waterline, the stability of the sand was deemed inadequate for supporting the SEWF. We removed 0.1 m (4 in.) of sand in this area and replaced it with 20 mm (3/4 in.) of angular stone to provide a well-drained and stable base, which would also reduce the amount of scour from wave action on the lake. The work crew consisted of employees of the park, the Wisconsin Department of Natural Resources, and the USDA Forest Service.

A lightweight landscaping geotextile fabric was placed on the sand and drainage rock. Handfuls of sand were thrown on the fabric to keep the wind from blowing it out of place. The geotextile fabric bonded to the SEWF and improved overall stability of the surface layer.

Bridle Path

Both bridle path sections were remote sites that required the use of hand tools for surface preparation. The surfaces were prepared by removing large rocks and woody forest debris.

One site consisted of two parallel ruts approximately 0.1 to 0.2 m (4 to 8 in.) deep and 0.2 to 0.3 m (8 to 12 in.) wide. The ruts were within 1 m (3 ft) apart on a 15% to 20% slope. Native soil was exposed along the ruts. The soil was firm with little loose soil or unstable rock.

The other site was a 3-m (12-ft) wide section on a bridle trail with a 20% to 25% slope leading to a level wash that carried water during heavy rains for very short periods. The primary objective was to stabilize the soil from the erosive forces of horse hooves and water running across the wash.

Bonded Beach Path Installation

The two binder systems used to fabricate the beach path surface were

-

an acrylic and polyvinyl acetate polymer emulsion, SoilSement (Midwest Industrial, Canton, Ohio), mixed 30% by dry weight of solids to unit weight of dry EWF and applied 63 mm (2-1/2 in.) thick, and

-

a non-foaming polyurethane, Vitri-Turf (Vitricon, Polymer Plastics Corp., Commack, New York), mixed 30% by weight with unit dry weight of EWF and applied 37 mm (1-1/2 in.) thick.

Because the installation occurred in the fall, we monitored air temperature; both stabilizing binders required 4°C (40°F) for proper curing. On the date of installation, the overnight temperature was 7°C (44°F). The binders had been stored at room temperature. When the binders were mixed with EWF, the temperature of the mixture was well above 10°C (50°F). The EWF was shoveled directly from the truck into a 160-L (40 gal) portable mortar mixer. The amount of binder added was determined as a proportion (30%) of EWF dry weight (volumetrically equivalent to 0.041 m3 (1.45.ft3) of EWF to 5.3 L (1.25 gal) of Vitri-Turf or 10.6 L (2.5 gal) of SoilSement. Weight proportion was 77:23. The binder and EWF were mixed for approximately 2 min and transported to the target pad in polyethylene tray wheelbarrows (Fig. 3). The binder-EWF mixture was spread with hand tools to an even thickness (Figs. 4 and 5). The area was then compacted and flattened with a 1.2-m by 1.2-m by 16-mm (4-ft by 4-ft by 5/8-in.) piece of plywood covered with a polyethylene release sheet. A 90-kg (198-lb) person walked on the plywood in each quadrant to apply firm compaction pressure. At the termination of the path at the waterline a 0.1-m (3.5-in.) curb was formed to reduce any inadvertent rolling of the path into the water and to stiffen the edge directly in contact with wave action.

Figure 2-Grading of beach path to waterline.

Figure 3-Loading of binder-EWF mixture from mortar mixer into wheelbarrow.

Figure 4-Leveling and compaction of binder-EWF mixture near junction with asphalt path.

Figure 5-Termination of Soil-Sement portion of beach path. Geotextile fabric visible under completed SEWF surface.

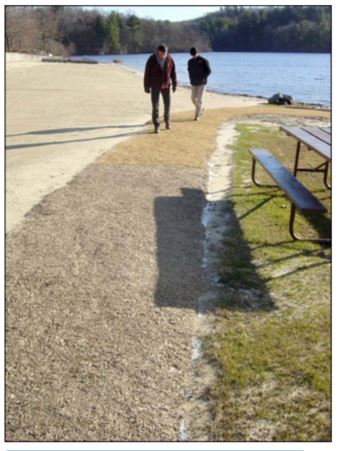

The two SEWF surfaces were allowed to cure or bond for 5 days prior to use (Fig. 6). Because rain was not predicted, the entire surface was left exposed. Overnight temperatures stayed above 4°C (40°F) for 2 days after installation. Within 2 h of installing the Vitri-Turf, the surface was somewhat rigid to hand pressure. The Soil-Sement surface was slower to stiffen and was deemed stiff within 48 h. Five days after installation, the barriers were removed and the edge of the path was backfilled with beach sand using rakes. The completed beach path after 2 months of weathering is shown in Figure 7.

Bonded Bridle Path Installation

The same two binder systems used to fabricate the beach path surface (Soil-Sement and Vitri-Turf) were used for the bridle path trials.

Prior to the date of installation, the overnight temperature was 9°C (48°F). The binders had been stored at room temperature; when mixed with EWF, the resultant mixture was well above 10°C (50°F).

Figure 6-Completed beach path area looking west, shown with temporary barrier for 5-day SEWF curing period.

Figure 7-Beach path after 2 months of weathering. Junction of Soil-Sement and Vitri-Turf surfaces is just above the shadow cast by the picnic bench.

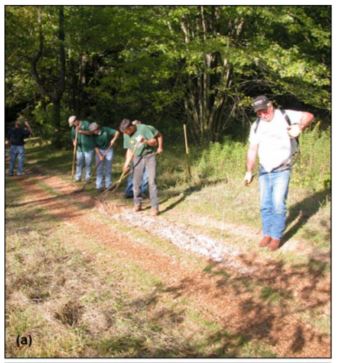

For both systems, the layer of EWF placed on the soil surface was 0.05 to 0.07 m (2 to 3 in.) deep and was raked smooth. A backpack sprayer and drip-bucket were used to apply the Soil-Sement (approximately 50% solids content) with a target application proportion of 30% binder based on the weight/volume of EWF (Figs. 8 and 9). The Vitri-Turf was much more viscous (100% solids) and thus only a drip bucket approach was used to apply the binder (Fig. 10). With a known weight of EWF at an application proportion of 30%, 19 L (5 gal) of binder was applied by moving a perforated bucket (holes 6 mm (0.2 in.) in diameter) quickly over the surface. Immediately after applying the binder, the binder was mixed into the EWF with forks and garden rakes. On the narrow bridle path, the SEWF was compacted using the flat end of a rake. The wider path was compacted using a polyethylene-covered 1.2-m by 1.2-m by 16-mm (4-ft by 4-ft by 5/8-in.) piece of plywood; a 90-kg (198-lb) person walked on the plywood in each quadrant to apply firm compaction pressure (Fig. 11). The SEWF areas were roped off for 5 days to provide time for curing prior to usage.

Figure 8-Installation of Soil-Sement surface on bridle path: (a) application of Soil-Sement by backpack-type sprayer; (b) trail crew mixed, leveled, and compacted the narrow trail filled with SEWF.

Figure 9-Application of Soil-Sement to bridle trail by drip-bucket method. Rakes were used to mix binder with EWF and level the trail.

Figure 10-Application of Vitri-Turf to bridle trail by drip-bucket method. Holes drilled in bottom of 19-L (5-gal) container allowed uniform application over 0.4- by 20-m (1.3- by 66-ft) trail.

Figure 11-Treatment of wide bridle trail (site 2): spray application of Vitri-Turf in background and drip-bucket application of Soil-Sement in foreground. Note use of polyethylene-covered plywood for compaction and leveling of Vitri-Turf SEWF.

Test Procedures

Field Observation Reports

The sites were not under direct supervision or observation by park staff or other responsible personnel. However, on-duty staff noted any public concerns and changes at the site and reported them when we visited. Forest Products Laboratory staff visited the sites at least weekly for the first 2 months and at least monthly thereafter (if the ground was thawed) to complete the rotational penetrometer testing and to observe and annotate any maintenance needs.

Impact Attenuation Tests

Impact tests were completed on the beach path only as an adjunct to tests conducted at a playground at another park. For the beach path, we were interested if the impact standard could be met when SEWF was placed over sand. The impact was conducted by a cooperator (Zeager Bros. Inc., Middletown, Pennsylvania) 8 weeks after installation. ASTM F 1292-99 test specifications (ASTM 1999a) and F355-95 test methods (ASTM 1995) were used at a test drop height of 3.05 m (10.0 ft) and 1.83 m (6.0 ft), respectively. Maximum g levels and head injury criteria (HIC) were measured.

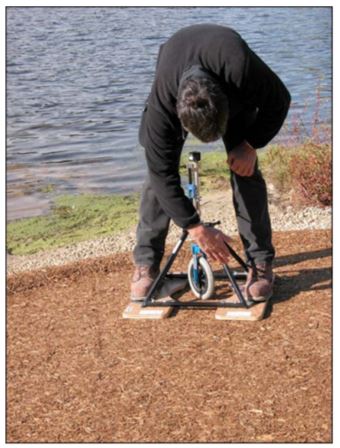

Accessibility and Durability Measures

The beach path surfaces were periodically measured with a rotational penetrometer. This device subjects the test surface to a low-speed rotational bearing test meant to simulate the weight and action of a front caster wheel on a wheelchair. The procedures are based on the draft national standard test method for the firmness and stability of ground and floor surfaces (RESNA 2000), which uses an average of five readings. This test provides objective measures of surface firmness and stability. Although no literature has been published on this subject, the use of the rotational penetrometer data allows an inference to the durability of the binder-EWF surface. The test effectively detects the loss of bond strength during the stability (rotation of caster wheel) portion of the test. The firmness measure is a means of inferring changes in overall stiffness of the bonded layer as well. It has been correlated to the work measurement of ASTM F1951 (ASTM 1999b), "Accessibility of Surface Systems," for a wide array of surfacing and floor coverings. The test was performed 1 week after surface installation and as often as once a week initially, using a Beneficial Designs, Inc. (Minden, Nevada) rotational penetrometer and protocol for assessing the bearing/rotational indentation on each surface (Axelson and Chesney 1999).

Observations and Results

Field Observations

A wheelchair user on the beach path described the Vitri-Turf surface as "nice and firm" and the Soil-Sement surface as "kind of soft"( Fig. 12). Maneuvering the chair was noted to be "easy" on the Vitri-Turf and "not as easy" on the SoilSement. The user also noted that the raised curb made her feel comfortable about moving to the end of the path. Without the curb, she felt she would have had to stop a few feet back from the water's edge.

The bridle paths suffered near total loss of integrity within the first 2 months of installation. Shoed horse hooves broke the thin 50- to 70-mm (2- to 3-in.) surfaces. Material was first broken into dinner-plate-sized pieces and then smaller pieces. The horses did not avoid the SEWF area and were clearly comfortable walking on it. Although a thicker surface would have lasted longer, the clear implication is that equestrian traffic requires a much tougher surface to resist the forces applied. Because this system failed prematurely due to mechanical loads, it did not remain in place long enough to confirm its ability to control trail erosion.

Figure 12-Testing bonded beach path with (a) battery-powered and (b) hand-powered wheelchairs. Shadow near the waterline indicates terminal curb of beach path.

Impact Attenuation

Impact testing (ASTM F1292, ASTM 1999)) of the Vitri Turf and Soil-Sement surfaces was conducted 8 weeks after installation (Fig. 13).

For the second and third drop tests at 3.05 m (10 ft),

-

average g readings were 223 for Vitri-Turf and 238 for Soil-Sement and

-

average HIC readings were 1679 for Vitri-Turf and 1752 for Soil-Sement.

For the second and third drop tests at 1.82 m (6 ft)

-

average g readings were 214 for Vitri-Turf and 196 for Soil-Sement and

-

average HIC readings were 1370 for Vitri-Turf and 1214 for Soil-Sement.

Figure 13-Impact testing on beach path was similar to impact test conducted at a playground using a 3.05-m (10-ft) drop-height.

Recall that these recreational trails were installed directly on the sand and not on the 0.3 m (12 in) of EWF found at a typical playground site. If the trails were evaluated as play surfaces, both beach path SEWF surfaces would fail the criteria of <200 for g and <1,000 for HIC. When using the 1.82-m (6-ft) fall height (which would be appropriate for people of average height playing volleyball), the SoilSement surface was just able to meet the g criteria but failed the HIC. However, given the alternatives available, both surfaces are softer and less likely to cause injury than is an asphalt path.

Durability

Measures of surface durability are quite subjective unless the loss of durability is a dramatic failure. The curing of SoilSement, as evidenced by the stiffening of the SEWF mixture, was slower than that of the Vitri-Turf, and the SoilSement surface was "softer" according to one wheelchair user. In the rotational penetrometer test, the Soil-Sement SEWF showed some indication for the top surface particles to detach from the overall top layer faster than did the VitriTurf SEWF top particles. The rotational penetrometer readings also reflected changes in stability and firmness of the Soil-Sement surface.

Vitri-Turf SEWF durability with exposure to weather was good and reflected our experience with this material during the past 2 years at the Phase II test site at the Forest Products Laboratory in Madison, Wisconsin. During the spring of 2004 Wisconsin experienced record-setting rainfalls. This caused the level of Cox Hollow Lake in Governer Dodge State Park to rise over 0.3 m (1 ft) for a short period. Park staff reported that the path "floated" off the gravel pad at the path terminus for a distance of approximately 2 m (6-1/2 ft). After the water had subsided, there was no evidence that the path had been lifted and the overall performance of the surface seemed comparable to that noted before the high water level.

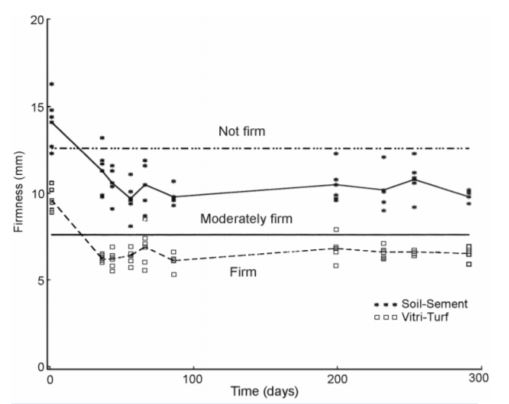

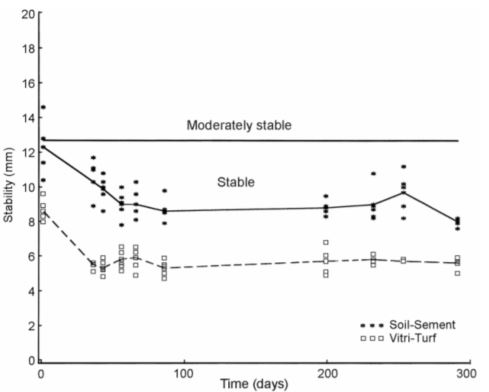

Accessibility Measures

During the 10-month period of this testing, the firmness and stability of the SEWF surfaces were measured with the rotational penetrometer (Fig. 14). Both the Vitri-Turf and Soil-Sement showed good performance for accessibility during this period. The Vitri-Turf SEWF indicated "firm" and "stable" during the entire period, with some fluctuation traceable to the changes in moisture with long rainy spells. Soil-Sement SEWF was rated as "moderately firm" and "stable" during the testing period (Figs. 15 and 16).

Figure 14-Rotational penetrometer used to measure accessibility.

Figure 15-Firmness of Soil-Sement and Vitri-Turf treatments on beach path over first 10 months of installation.

Figure 16-Stability of Soil-Sement and Vitri-Turf treatments on beach path over first 10 months of installation.

Costs and Personnel Time for Beach Path Installation

The following summary of costs and time estimates is not meant to be definitive but to document data for the beach path installation.

Quantity of material

EWF 6 yd3

Vitri-Turf 15 gal

Soil-Sement 35 gal (45% solids)

Market value of material

EWF $21/yd uncompacted (includes shipping) $126

Vitri-Turf $18/gal (100% solids, 11 lb/gal) 270

Soil-Sement $7/gal (45% solids, 9 lb/gal) 245

Drainage system Geotextile 80

$721

Equipment and tool rental (market value) $100

Personnel time

Base prep and geotextile installation, 4 h @ $10/h $40

Bonded surface install, 16 h @ $15/h 240

The installation of the two surface treatments was completed during one workday. Approximate efforts for the installation of 200 ft2 of each material (400 ft2 total) were 16 h (4 people for 4 h).

Summary of costs for beach path surface

| Cost ($/ft2) | |||

| Binder | Labor | Materials | Surface w/labor |

| Vitri-turf (38 mm, 1.5 in.) | 0.70 | 1.87 | 2.57 |

| Soil-Sement (63.5 mm, 2.5 in.) | 0.70 | 1.74 | 2.44 |

Preliminary Guidelines for SEWF Installation

Follow manufacturer's instructions for storage and handling of the binder. Binder materials must be stored indoors in cool dry storage out of sunlight. Observe recommended limits on binder shelf life. Read material safety data sheets carefully prior to opening containers. Wear protective clothing and eye gear at all times. Assure a period of 48 h of warm and dry weather for proper curing of the binders. EWF should be moderately dry (less than 30% moisture content).

Mixing Binder With EW

1a. Vitri-Turf binder is mixed with the EWF at the ratio of 77/23 by weight. This equates to approximately 6 liters (1.25 gallons) of Vitri-Turf binder to 0.041 m3 (1.45 ft3) of EWF (depending upon the density of the EWF particles).

1b. Soil-Sement is mixed 77/23 by weight (assuming 100% solids). If it is only 50% solids then the ratio of weights changes to 63/37. This equates to 10 L (2.5 gallons of Soil-Sement) (50% solids) to 0.041 m3 (1.45 ft3) of EWF.

2. Mixing is best done with a mechanical drum mixer. If a small patch is needed for repair, use a trough with a hoe. Be sure that the EWF particles are thoroughly coated. Running a typical mortar or cement mixer for 2 min is usually adequate to achieve good mixing. Check the mixer at the end of each mix to assure that binder and fine wood particles are not accumulating on the paddles or drum.

Application of SEWF

1. Use a wheelbarrow to transport the SEWF mixture. Dump into place and apply the mixed Binder/EWF at a nominal 50% more (uncompacted) depth than the intended compacted thickness using a screed bar or rake.

2. Compact and smooth the surface by using a large trowel or stiff plywood (16 mm or 5/8 in.) of dimension 1.2 by 1.2 m (4 by 4 ft) covered with a heavy-mil sheet of polyethylene as a release. If material sticks, you may lubricate with kerosene, diesel fuel, or soapy water. Do not saturate surface with these lubricants. After compaction the thickness will be approximately 40 mm (1.6 in.).

3. Apply a moderate downward pressure onto the surface so that the mixture compacts tightly. When using the 4- by 4-ft plywood, a 90-kg (200-lb) person stepping in the four quadrants of the panel should provide adequate compaction.

4. Allow to cure in the open air for a minimum of 24 h. Cover only for short periods to protect the surface from direct rainfall.

Cleanup

Clean all tools for Vitri-Turf application immediately with diesel fuel before the surface has dried; use water to clean tools for Soil-Sement application. Once binder has dried it will be difficult to remove from tools, surfaces, or hands.

General Precautions

-

Wear protective clothing and eye gear.

-

Provide a minimum of 1% slope for all substrates for drainage.

-

Ambient air temperature should be 40°F (4°C) or greater and rising when SEWF is applied. Air temperature should remain at 40°F (4°C) or greater for at least 7 days after SEWF application.

-

Protect surfaces from rain for a minimum of 48 h after SEWF application.

-

Read all material safety data sheets very carefully. If you do not understand the instructions, contact the manufacturer before applying SEWF.

-

If binder accidentally comes in contact with eyes, immediately rinse with water and contact a physician.

Literature Cited

ADA. 1990. Public Law 101-336. Americans with Disabilities Act, Public Law 336, 101st Congress, enacted July 26, 1990.

ASTM. 1995. Standard test method for shock-absorbing properties of playing surface systems and materials.

ASTM F355-95, Vol. 15.07. West Conshohocken, PA: American Society for Testing and Materials.

ASTM. 1999a. Standard specification for impact attenuation of surface systems under and around playground equipment. ASTM F1292-99. West Conshohocken, PA: American Society for Testing and Materials.

ASTM. 1999b. Standard specification for determination of accessibility of surface systems under and around playground equipment. ASTM F1951.West Conshohocken, PA: American Society for Testing and Materials.

ASTM. 2004. Standard specification for engineered wood fiber for use as a playground safety surface under and around playground equipment. F2075-04, Vol. 15.07. West Conshohocken, PA: American Society for Testing and Materials.

Axelson, P.W.; Chesney, D. 1999. Accessible exterior surfaces. Tech. rep. Washington, DC: U.S. Architectural and Transportation Barriers Compliance Board.

www.accessboard.gov/research&training/Exterior%20Surfac es/exteriorsarticle.htm

Laufenberg T.; Winandy, J.E. 2003. Field performance testing of improved engineered wood fiber (EWF) surfaces for accessible playground areas. Gen. Tech. Rep. FPL-GTR-138. Madison. WI: U.S. Department of Agriculture, Forest Service, Forest Products Laboratory. 10 p.

Laufenberg T.; Krzysik, A.M.; Winandy, J.E. 2003. Improved engineered wood fiber (EWF) surfaces for accessible playgrounds, Gen. Tech. Rep. FPL-GTR-135. Madison. WI: U.S. Department of Agriculture, Forest Service, Forest Products Laboratory. 15 p.

National Center on Accessibility, Providing Access to Beaches. 2003. Access Today. Special Vol., Issue 9. (Summer).

http://www.ncaonline.org/monographs/9beach-access.shtml

RESNA, 2000. RESNA surface, section 1: Test method for firmness and stability. Working draft standard. Arlington, VA: Rehabilitation Engineering and Assistive Technology Society of North America. 11-20. info@resna.org

User Comments/Questions

Add Comment/Question