Bonded Bridle Path Installation

The same two binder systems used to fabricate the beach path surface (Soil-Sement and Vitri-Turf) were used for the bridle path trials.

Prior to the date of installation, the overnight temperature was 9°C (48°F). The binders had been stored at room temperature; when mixed with EWF, the resultant mixture was well above 10°C (50°F).

Figure 6-Completed beach path area looking west, shown with temporary barrier for 5-day SEWF curing period.

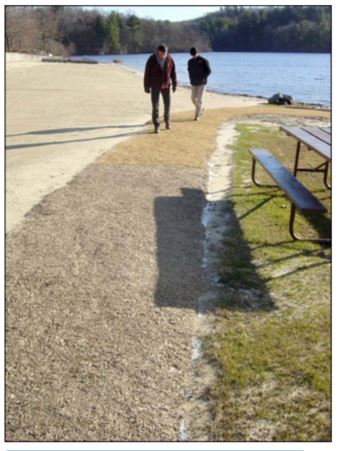

Figure 7-Beach path after 2 months of weathering. Junction of Soil-Sement and Vitri-Turf surfaces is just above the shadow cast by the picnic bench.

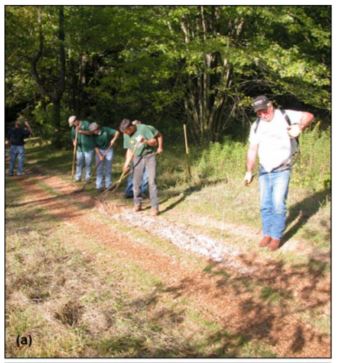

For both systems, the layer of EWF placed on the soil surface was 0.05 to 0.07 m (2 to 3 in.) deep and was raked smooth. A backpack sprayer and drip-bucket were used to apply the Soil-Sement (approximately 50% solids content) with a target application proportion of 30% binder based on the weight/volume of EWF (Figs. 8 and 9). The Vitri-Turf was much more viscous (100% solids) and thus only a drip bucket approach was used to apply the binder (Fig. 10). With a known weight of EWF at an application proportion of 30%, 19 L (5 gal) of binder was applied by moving a perforated bucket (holes 6 mm (0.2 in.) in diameter) quickly over the surface. Immediately after applying the binder, the binder was mixed into the EWF with forks and garden rakes. On the narrow bridle path, the SEWF was compacted using the flat end of a rake. The wider path was compacted using a polyethylene-covered 1.2-m by 1.2-m by 16-mm (4-ft by 4-ft by 5/8-in.) piece of plywood; a 90-kg (198-lb) person walked on the plywood in each quadrant to apply firm compaction pressure (Fig. 11). The SEWF areas were roped off for 5 days to provide time for curing prior to usage.

Figure 8-Installation of Soil-Sement surface on bridle path: (a) application of Soil-Sement by backpack-type sprayer; (b) trail crew mixed, leveled, and compacted the narrow trail filled with SEWF.

Figure 9-Application of Soil-Sement to bridle trail by drip-bucket method. Rakes were used to mix binder with EWF and level the trail.

Figure 10-Application of Vitri-Turf to bridle trail by drip-bucket method. Holes drilled in bottom of 19-L (5-gal) container allowed uniform application over 0.4- by 20-m (1.3- by 66-ft) trail.

Figure 11-Treatment of wide bridle trail (site 2): spray application of Vitri-Turf in background and drip-bucket application of Soil-Sement in foreground. Note use of polyethylene-covered plywood for compaction and leveling of Vitri-Turf SEWF.

User Comments/Questions

Add Comment/Question