2019 California Standards for Accessible Design Guide (effective January 1, 2020 with July 1, 2021 amendments)

11B-407.4 Elevator car requirements.

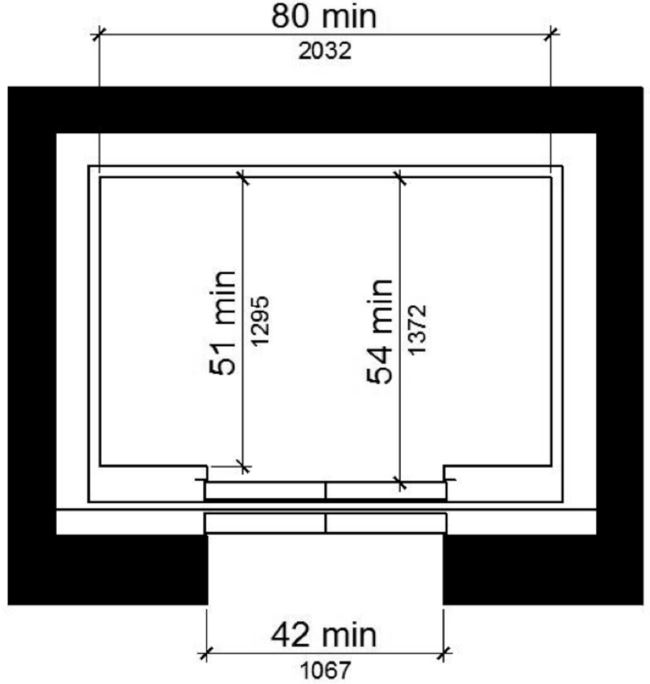

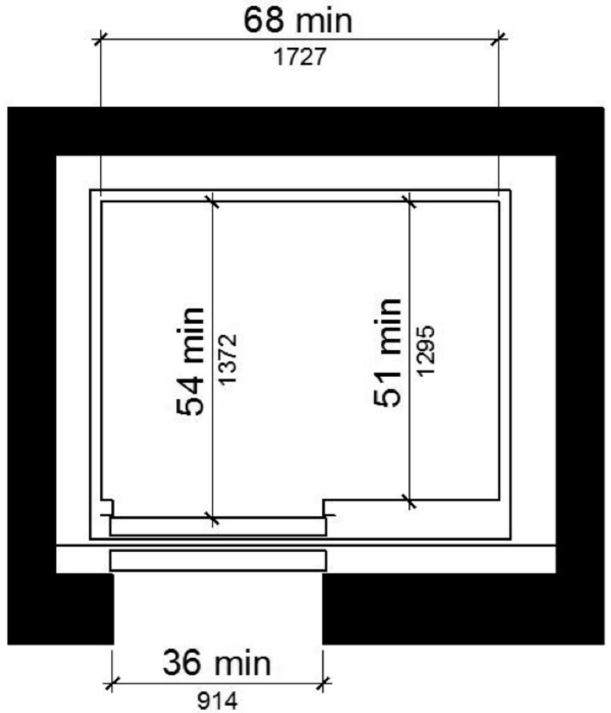

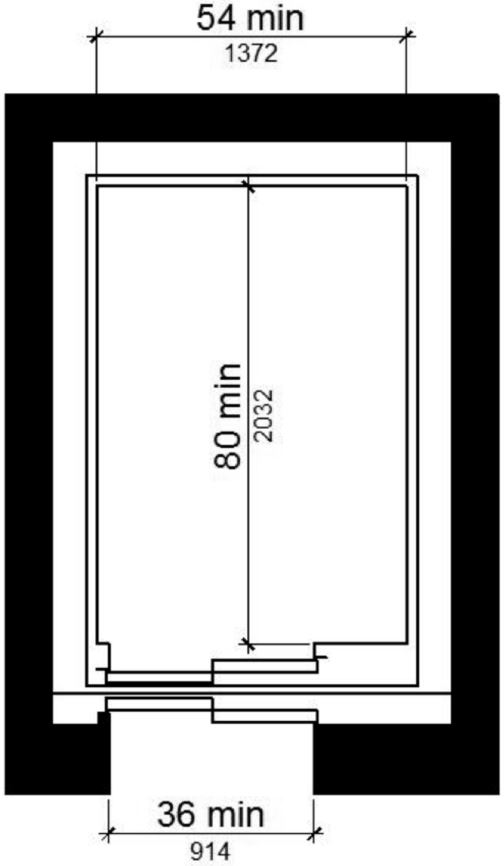

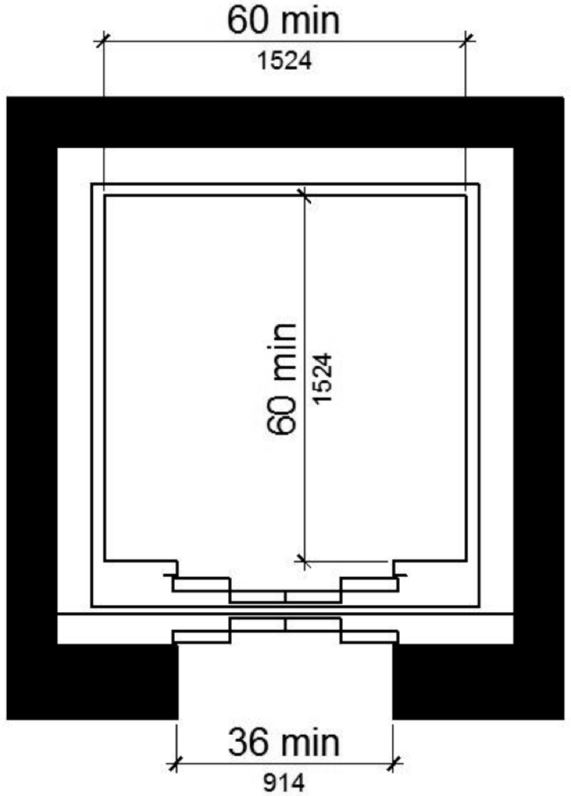

11B-407.4.1 Car dimensions.

Inside dimensions of elevator cars and clear width of elevator doors shall comply with Table 11B-407.4.1.

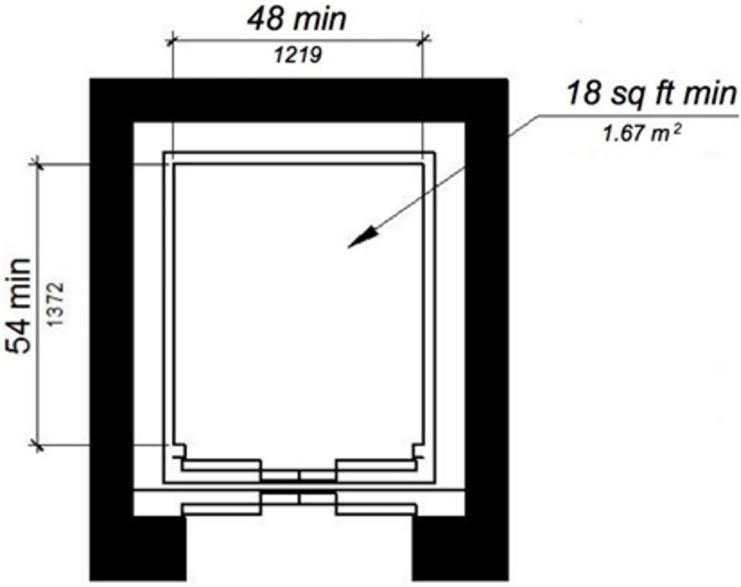

Exception: In existing buildings, where existing shaft configuration prohibits strict compliance with Section 11B-407.4.1, existing elevator car configurations that provide a clear floor area of 18 square feet (1.67 m2) minimum and also provide an inside clear depth 54 inches (1372 mm) minimum and a clear width 48 inches (1219 mm) minimum shall be permitted.

[2010 ADA Standards] EXCEPTION: Existing elevator car configurations that provide a clear floor area of 16 square feet (1.5 m2) minimum and also provide an inside clear depth 54 inches (1370 mm) minimum and a clear width 36 inches (915 mm) minimum shall be permitted.

ETA Editor's Note

The CBC Exception at 11B-407.4.1 is more stringent than that of 2010 ADA Standards regarding minimum car dimensions for existing elevators.

TABLE 11B-407.4.1 ELEVATOR CAR DIMENSIONS

|

MINIMUM DIMENSIONS |

||||

|---|---|---|---|---|

|

Door Location |

Door clear width | Inside car, side to side | Inside car, back wall to front return |

Inside car, back wall to inside face of door |

|

Centered |

42 inches (1067 mm) |

80 inches (2032 mm) |

51 inches (1295 mm) |

54 inches (1372 mm) |

|

Side (off-centered) |

36 inches (914 mm)1 |

68 inches (1727 mm) |

51 inches (1295 mm) |

54 inches (1372 mm) |

|

Any |

36 inches (914 mm)1 |

54 inches (1372 mm) |

80 inches (2032 mm) |

80 inches (2032 mm) |

|

Any |

36 inches (914 mm)2 |

60 inches (1524 mm)2 |

60 inches (1524 mm)2 |

60 inches (1524 mm)2 |

|

1. A tolerance of minus 5/8 inch (15.9 mm) is permitted. 2. Other car configurations that provide a turning space complying with Section 11B-304 with the door closed shall be permitted. |

||||

(a) centered door

(b) side (off-centered) door

(c) any door location

(d) any door location

(e) Exception existing elevator car configuration

FIGURE 11B-407.4.1 ELEVATOR CAR DIMENSIONS ‡‡

11B-407.4.2 Floor surfaces.

Floor surfaces in elevator cars shall comply with Section 11B-302 and 11B-303.

11B-407.4.3 Platform to hoistway clearance.

The clearance between the car platform sill and the edge of any hoistway landing shall be 1¼ inch (32 mm) maximum.

11B-407.4.4 Leveling.

Each car shall be equipped with a self-leveling feature that will automatically bring and maintain the car at floor landings within a tolerance of ½ inch (12.7 mm) under rated loading to zero loading conditions.

11B-407.4.5 Illumination.

The level of illumination at the car controls, platform, car threshold and car landing sill shall be 5 foot candles (54 lux) minimum.

11B-407.4.6 Elevator car controls.

Where provided, elevator car controls shall comply with Sections 11B-407.4.6 and 11B-309.4.

Exception: In existing elevators, where a new car operating panel complying with Section 11B-407.4.6 is provided, existing car operating panels may remain operational and shall not be required to comply with Section 11B-407.4.6.

11B-407.4.6.1 Location.

Controls shall be located within one of the reach ranges specified in Section 11B-308.

Exceptions:

- Where the elevator panel serves more than 16 openings and a parallel approach is provided, buttons with floor designations shall be permitted to be 54 inches (1372 mm) maximum above the finish floor.

- In existing elevators, car control buttons with floor designations shall be permitted to be located 54 inches (1372 mm) maximum above the finish floor when a parallel approach is provided.

11B-407.4.6.2 Buttons.

Car control buttons with floor designations shall comply with Section 11B-407.4.6.2.

Exception: Reserved.

[2010 ADA Standards] EXCEPTION: In existing elevators, buttons shall be permitted to be recessed.

11B-407.4.6.2.1 Size and shape. Buttons shall have square shoulders, be ¾ inch (19.1 mm) minimum in their smallest dimension and be raised 1/8 inch (3.2 mm) plus or minus 1/32 inch (0.8 mm) above the surrounding surface.

[2010 ADA Standards] 407.4.6.2.1 Size. Buttons shall be ¾ inch (19 mm) minimum in their smallest dimension.

11B-407.4.6.2.2 Arrangement.

Buttons shall be arranged with numbers in ascending order. When two or more columns of buttons are provided they shall read from left to right.

11B-407.4.6.2.3 Illumination.

Car control buttons shall be illuminated.

11B-407.4.6.2.4 Operation.

Car control buttons shall be activated by a mechanical motion that is detectable.

11B-407.4.6.3 Keypads.

Car control keypads shall be in a standard telephone keypad arrangement and shall comply with Section 11B-407.4.7.2.

11B-407.4.6.4 Emergency controls.

Emergency controls shall comply with Section 11B-407.4.6.4.

11B-407.4.6.4.1 Height.

Emergency control buttons shall have their centerlines 35 inches (889 mm) minimum above the finish floor.

11B-407.4.6.4.2 Location.

Emergency controls, including the emergency alarm, shall be grouped at the bottom of the panel.

11B-407.4.7 Designations and indicators of car controls.

Designations and indicators of car controls shall comply with Section 11B-407.4.7.

Exception: In existing elevators, where a new car operating panel complying with Section 11B-407.4.7 is provided, existing car operating panels may remain operational and shall not be required to comply with Section 11B-407.4.7.

11B-407.4.7.1 Buttons.

Car control buttons shall comply with Section 11B-407.4.7.1.

11B-407.4.7.1.1 Type.

Control buttons shall be identified by raised characters or symbols, white on a black background, complying with Section 11B-703.2 and Braille complying with Section 11B-703.3.

[2010 ADA Standards] 407.4.7.1.1 Type. Control buttons shall be identified by tactile Characters complying with 703.2.

11B-407.4.7.1.2 Location.

Raised characters or symbols and Braille designations shall be placed immediately to the left of the control button to which the designations apply.

Exception: Reserved.

[2010 ADA Standards] EXCEPTION: Where space on an existing car operating panel precludes tactile markings to the left of the controls, markings shall be placed as near to the control as possible.

11B-407.4.7.1.3 Symbols.

The control button for the emergency stop, alarm, door open, door close, main entry floor, and phone, shall be identified with raised symbols and Braille as shown in Table 11B-407.4.7.1.3.

TABLE 11B-407.4.7.1.3 ELEVATOR CONTROL BUTTON IDENTIFICATION

|

Control Button |

Tactile Symbol |

Braille Message |

|

Emergency Stop |

|

"ST"OP Three cells |

|

Alarm |

|

AL"AR"M Four cells |

|

Door Open |

|

OP"EN" Three cells |

|

Door Close |

|

CLOSE Five cells |

|

Main Entry Floor |

|

MA"IN" Three cells |

|

Phone |

|

PH"ONE" Four cells |

11B-407.4.7.1.4 Visible indicators.

Buttons with floor designations shall be provided with visible indicators to show that a call has been registered. The visible indication shall extinguish when the car arrives at the designated floor.

11B-407.4.7.1.5 Button spacing.

A minimum clear space of 3/8 inch (9.5 mm) or other suitable means of separation shall be provided between rows of control buttons.

11B-407.4.7.2 Keypads.

Keypads shall be identified by characters complying with Section 11B-703.5 and shall be centered on the corresponding keypad button. The number five key shall have a single raised dot. The dot shall be 0.118 inch (3 mm) to 0.120 inch (3.05 mm) base diameter and in other aspects comply with Table 11B-703.3.1.

ETA Editor's Note

The preceding CBC requirements for elevator controls at 11B-407.4.6 and 11B-407.4.7 are more stringent than those of 2010 ADA Standards.

11B-407.4.8 Car position indicators.

Audible and visible car position indicators shall be provided in elevator cars.

11B-407.4.8.1 Visible indicators.

Visible indicators shall comply with Section 11B-407.4.8.1.

11B-407.4.8.1.1 Size.

Characters shall be ½ inch (12.7 mm) high minimum.

11B-407.4.8.1.2 Location.

Indicators shall be located above the car control panel or above the door.

11B-407.4.8.1.3 Floor arrival.

As the car passes a floor and when a car stops at a floor served by the elevator, the corresponding character shall illuminate.

Exception: Reserved.

[2010 ADA Standards] EXCEPTION: Destination-oriented elevators shall not be required to comply with 407.4.8.1.3 provided that the visible indicators extinguish when the call has been answered.

11B-407.4.8.1.4 Reserved

[2010 ADA Standards] 407.4.8.1.4 Destination Indicator. In destination-oriented elevators, a display shall be provided in the car with visible indicators to show car destinations.

11B-407.4.8.2 Audible indicators.

Audible indicators shall comply with Section 11B-407.4.8.2.

11B-407.4.8.2.1 Signal type.

The signal shall be an automatic verbal annunciator which announces the floor at which the car is about to stop.

Exception: For elevators that have a rated speed of 200 feet per minute (1 m/s) or less, a non-verbal audible signal with a frequency of 1500 Hz maximum which sounds as the car passes or is about to stop at a floor served by the elevator shall be permitted.

11B-407.4.8.2.2 Signal level.

The verbal annunciator shall be 10 dB minimum above ambient, but shall not exceed 80 dB, measured at the annunciator.

11B-407.4.8.2.3 Frequency.

The verbal annunciator shall have a frequency of 300 Hz minimum to 3000 Hz maximum.

11B-407.4.9 Emergency communication.

Emergency two-way communication systems shall comply with Section 11B-308. Raised symbols or characters, white on a black background, and Braille shall be provided adjacent to the device and shall comply with Sections 11B-703.2 and 11B-703.3. Emergency two-way communication systems between the elevator and a point outside the hoistway shall comply with ASME A17.1.

[2010 ADA Standards] 407.4.9 Emergency Communication. Emergency two-way communication systems shall comply with 308. Tactile symbols and Characters shall be provided adjacent to the device and shall comply with 703.2.

11B-407.4.10 Support rail.

Support rails shall be provided on at least one wall of the car.

There is no requirement for support rails inside elevator cars in 2010 ADA Standards.

11B-407.4.10.1 Location.

Clearance between support rails and adjacent surfaces shall be 1½ inches (38 mm) minimum. Top of support rails shall be 31 inches (787 mm) minimum to 33 inches (838 mm) maximum above the floor of the car. The ends of the support rail shall be 6 inches (152 mm) maximum from adjacent walls.

11B-407.4.10.2 Surfaces.

Support rails shall be smooth and any surface adjacent to them shall be free of sharp or abrasive elements.

11B-407.4.10.3 Structural strength.

Allowable stresses shall not be exceeded for materials used when a vertical or horizontal force of 250 pounds (1112 N) is applied at any point on the support rail, fastener, mounting device, or supporting structure.

User Comments/Questions

Add Comment/Question