Visual Detection of Detectable Warning Materials by Pedestrians with Visual Impairments - Final Report

1.5 Materials

Sidewalks. Four different colors of simulated sidewalk surfaces were used in this study. These included white (simulating new concrete), brown (simulating aged, dirty concrete), dark gray (simulating asphalt), and red (actual paving bricks). The four simulated sidewalk sections were constructed on low wooden platforms; each covered a 1.22 m (4 ft) wide x 2.44 m (8 ft) long level area on the ground. The white and brown “concrete” surfaces were simulated by applying several coats of paint and sand mixture to a sheet of OSB plywood (oriented strand board). The surface texture provided by the OSB plywood and paint/sand mixture approximated the surface texture of brushed concrete. Dark gray asphalt rolled roofing material was glued on OSB plywood to simulate dark gray asphalt pavement, and red colored concrete paving bricks were laid (without mortar joints) to simulate the brick sidewalk. The surface of each simulated sidewalk section was raised approximately 76 mm (3 in.) above the ground level. Chromaticity and luminous reflectance measurements of the simulated sidewalk surfaces used in this study are given in Table 3.

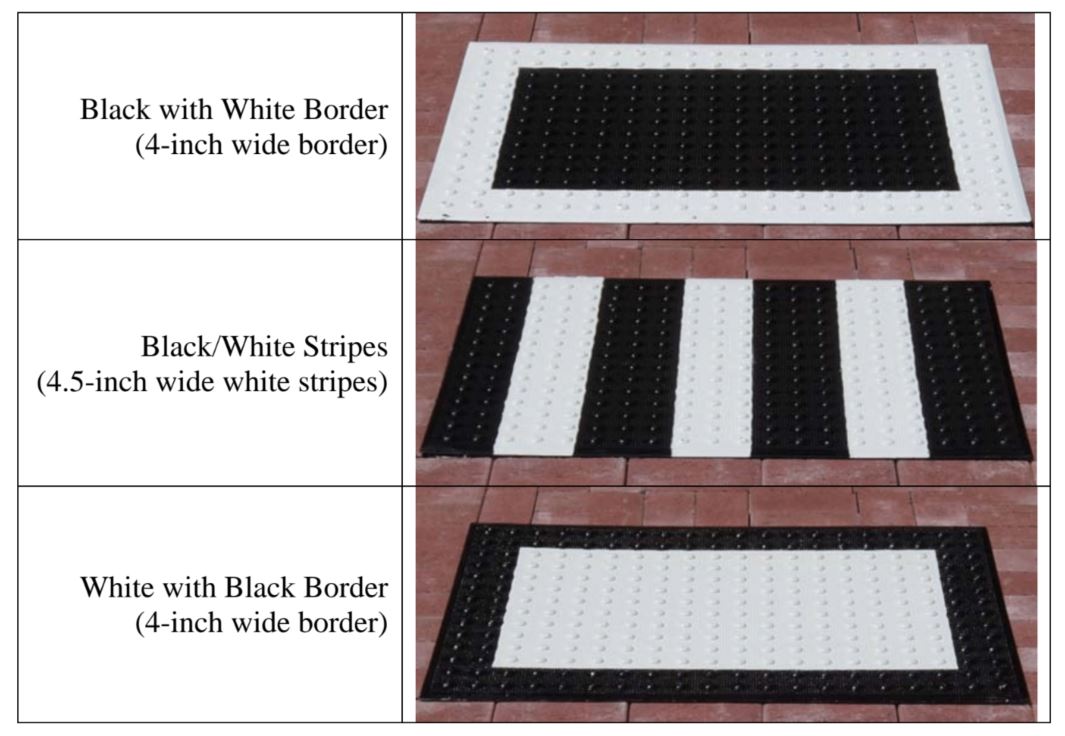

Detectable Warnings. Thirteen different detectable warnings were tested in this study. Ten were uniformly colored and three others had black-and-white patterns. Although two-color detectable warnings are not comm only used, we included a few high contrast patterns in this study to determine if patterns might be more effective than uniformly colored detectable warnings. Other colored patterns might have been tested but we chose to limit the number of detectable warnings used in the study to 13 so a participant could complete a full set of trials in a single two-hour session. The 10 uniformly colored detectable warnings are shown in Figure 2 with color samples. The three black-and- white patterned detectable warnings are shown in Figure 3, photographed against the red brick sidewalk.

Figure 2. Photo. Uniformly Colored Detectable Warnings (Color Samples)

Figure 3. Photo. Black-and-white Patterned Detectable Warnings

The detectable warnings were surface-mounted composite panels provided by ADA Armor-Tile. The panels were .89 m (35 in.)x .65 m (25.5 in.) including a 13 mm (0.5 in.) smooth tapered edge on all sides. The spacing and size of the truncated domes were compliant with Federal geometric specifications (see Appendix B). The detectable warnings also had very small bumps located between and on the truncated domes to provide texture for traction. Because this study was designed to examine the relative visibility of different detectable warning colors, materials from a single manufacturer were used so that the geometric characteristics of the truncated dome pattern would be constant for all of the different colors tested. Some of the colors selected for inclusion in the study were standard colors provided by the manufacturer, and some of the colors were created by painting the detectable warning panels. The relatively thin surface-mounted detectable warnings were chosen for use in this study because they could be lifted easily by a single experimenter. However, because they were not permanently mounted according to the manufacturer’s specifications, the detectable warnings had a tendency not to lie completely flat on the sidewalk. To overcome this problem, several thin metal plates were glued to the bottom of each detectable warning and magnets were embedded in the sidewalks, flush with the surface. This system served to hold the detectable warning panels flat against the sidewalk but allowed them to be quickly removed and replaced between different trials during the course of the study. When in place, the front edge of each detectable warning was positioned 1.22 m (4 ft) behind the front edge of the sidewalk and was centered horizontally on the sidewalk section.

Blanks. Blank panels were also created for this study. Blanks were made from thin sheets of painted plastic or asphalt roofing material approximately the same size as the detectable warnings. These blanks were the same color as the sidewalks and had no truncated domes. Blanks provided very little visual contrast against the sidewalk and were included in the study to ensure that participants could not simply assume that a detectable warning was present on every trial. Like the detectable warnings, the blanks cast small shadows along their front edges which ensured that participants could not simply use the presence of a thin shadow as a cue to determine that a detectable warning was present on the sidewalk. Blank panels were used with the white, brown, and asphalt sidewalks, but not with the brick sidewalk.

Chromaticity and Reflectance of Materials. Chromaticity and reflectance are physically measurable qualities that are related to the perceived color and lightness of surfaces. The chromaticity and reflectance of detectable warnings, sidewalks, and blank panel surfaces were measured in place (horizontal) at the testing site. Table 3 shows the chromaticity coordinates and reflectance factors of the materials used in this study. This set of chromaticity measurements was made between 10:00 a.m. and 11:00 a.m. under natural illumination (20% cloud cover) using a SpectraScan PR650 (PhotoResearch) spectrophotometer. The reflectance factors were measured on a different day using a Minolta CS-100 Chroma Meter. All measurements were made from the same direction that the surfaces were viewed by participants: at a downward angle of 45 degrees. Other details about the measurement procedures are given in Appendix D. Additional photometric measurements of real sidewalks at various locations in Rockville, Maryland confirmed that our simulated sidewalks had chromaticities and luminance reflectances that are plausible for actual paving materials.

Chromaticity and reflectance of the actual concrete sidewalks measured varied considerably depending on their age and dirtiness. For example, a new-looking, clean concrete sidewalk had a luminance reflectance of r = 0.49, while an older, much darker concrete sidewalk had a luminance reflectance of r = .09. Three asphalt sidewalks measured had luminance reflectance ranging from r = .06 to r = .10. Thus, from our limited measurements of real sidewalks, we conclude that the white simulated concrete sidewalk section used in the present study is similar to very light new concrete, and the simulated asphalt sidewalk is similar to new dark asphalt. The luminance reflectance of the brown simulated sidewalk is consistent with medium gray concrete sidewalks that we observed, although its appearance is more brownish. The red bricks used in the present study had similar luminance reflectance as bricks measured in existing sidewalks.

| Material |

CIE1931 Chromaticity Coordinates |

Reflectance Factor |

|---|---|---|

| White detectable warning | x = .333, y = .347 | .74 |

| Light Gray detectable warning | x = .326, y = .341 | .24 |

| White "concrete" detectable warning | x = .352, y = .364 | .64 |

| Brown " concrete" detectable warning | x = .390, y = .386 | .17 |

| Dark Gray detectable warning | x = .320, y = .331 | .09 |

| Federal Yellow detectable warning | x = .511, y = .454 | .46 |

| Pale Yellow detectable warning | x = .412, y = .414 | .47 |

| Bright Red detectable warning | x = .587, y = .323 | .11 |

| Orange-Red detectable warning | x = .533, y = .356 | .13 |

| Black detectable warning | x = .324, y = .338 | .02 |

| White paint (used for border & stripe patterns) | x = .330, y = .344 | .82 |

|

Black paint (used for border pattern) |

x = .326, y = .340 | .02 |

| Brick sidewalk (for a typical brick) | x = .417, y = .358 | .15 |

| Asphalt sidewalk | x = .332, y = .346 | .06 |

| Asphalt "blank" panel | x = .335, y = .349 | .05 |

| White sidewalk | x = .351, y = .363 | .57 |

| White "blank" panel | x = .351, y = .363 | .60 |

| Brown sidewalk | x = .385, y = .381 | .17 |

| Brown "blank" panel | x = .384, y = .381 | .17 |

User Comments/Questions

Add Comment/Question