Development of Surface Roughness Standards for Pathways Used by Wheelchair Users: Final Report

1. Background

People with disabilities can participate in the community and have very active lifestyles. A study has shown that people in Pittsburgh who use power WCs as their primary mode of transportation will travel 1.6 km on a normal day. (Cooper, et al., 2002) However, in an active and highly accessible environment, such as the convention centers and cities where they hold the National Veterans Wheelchair Games (NVWG), WC users can travel up to almost 8 km per day. (Cooper, et al., 2002) A similar study of manual WC users revealed that on typical days they travel 2.0 km, and in a highly accessible setting, such as at the NVWG, they will travel an average of 6.5 km per day; one subject in this study traveled 19.4 km in one day. (Tolerico, 2006)

A factor that influences this activity level is the degree to which the WC rider is comfortable and safe during these activities. One measure of comfort and safety is to determine the Whole Body Vibrations (WBV) exposure levels to which WC users are exposed. There is a wide body of occupational hazards research that has demonstrated a correlation from WBV exposure to discomfort and injury to nearly all of the body’s organs. Research suggests that exposure to shock and vibration may be linked to many symptoms such as muscle fatigue (Zimmerman, 1993), back injury (Pope, 1992; Pope, 1999), neck pain (Boninger et al, 2003) and disc degeneration. Literature suggests that the seated posture, which occurs during WC use, is a compromising position for the spine and many associated body tissues. Daily shock and vibration experienced during WC riding can also increase an individual’s rate of fatigue (VanSickle et al, 2001) and limit their functional activity and community participation. Because of these harmful effects, it is critical to understand and attempt to reduce the amount of WBVs that are transmitted when navigating over rough terrains. (Cooper et al, 2004; Requejo et al, 2009)

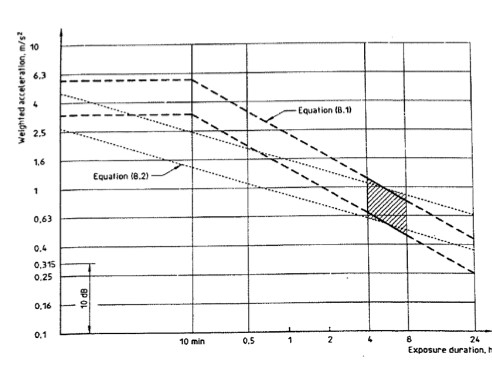

The ISO 2631-1 standard for evaluation of human exposure to whole-body vibration is the most accepted standard for vehicle vibration studies and establishes limits for safety, fatigue and comfort called the exposure caution zone. The exposure caution zone (Figure 1) is based upon the time of exposure and weighted magnitude of acceleration and reflects the maximum allowable limit for human safety. Furthermore, according to the ISO 2631-1, an RMS value of approximately 1.15 m/s2 over a 4-8 hour period is the maximum allowable vibration value. However, exposure of vibration levels within the caution zone may still result in elevated risk of health impairment (ISO, 1997) if they occur repeatedly over a long period of time (e.g. several years).

Figure 1: ISO Standard 2631-1. The health guidance zone is between the dashed lines

Legislation

The Architectural Barriers Act of 1968 (ABA) ensures that buildings which are designed, built or altered by federal funding or leased by federal agencies are accessible to the public. The Americans with Disabilities Act of 1990 (ADA) greatly expands the scope and details of the ABA. The ADA states that "physical or mental disabilities in no way diminish a person’s right to fully participate in all aspects of society…" It is a purpose of the ADA "to provide a clear and comprehensive national mandate for the elimination of discrimination against individuals with disabilities and to provide clear, strong, consistent, enforceable standards addressing discrimination against individuals with disabilities." Title V of the ADA mandated that the Architectural and Transportation Barriers Compliance Board (Access Board) set up minimum guidelines "to ensure that buildings, facilities, rail passenger cars, and vehicles are accessible, in terms of architecture and design, transportation, and communication, to individuals with disabilities." (ADA, 1990)

The Access Board has established ADA Accessibility Guidelines (ADAAG) for Buildings and Facilities that give specific instructions and limitations about what is considered accessible. However, the only guidelines related to floor or ground surfaces are that they "shall be stable, firm, and slip resistant." (ADA, 1990) Unfortunately, these restrictions can be interpreted differently and do not directly address the issue of surface roughness. Typical ADA accessible pathways are made of asphalt, pavement and concrete; however, packed crushed stone, gravel fines compacted with a roller, packed soil and other natural materials bonded with synthetic materials can provide the required degree of stability and firmness. The current ADAAG guidelines (Table 1) provide a description of the suggested width and slope, but do not provide guidance on pathway roughness except that obstacles should be no more than 1/2" high. The frequency (obstacles per unit length), profile, and orientations of safe and passable obstacles are not prescribed. (ADAAG, 2002) The absence of roughness guidelines is an unfortunate limitation to the ADAAG, as there are many stakeholders involved in the development processes and construction of public walkways (city planners, community councils, architects and contractors) each of which are not likely to understand the implications of terrain characteristics on the health, comfort and safety of WC riders.

Table 1: ADAAG- Accessible Route Guidelines

|

Parameter |

Requirement |

|

Clear Width |

Minimum 36" |

|

Openings |

Maximum 1/2" |

|

Obstacle Height |

|

|

1/4" |

No slope required |

|

1/4"-1/2" |

Beveled with Maximum 1:2 slope |

|

Ramps Max Slope |

|

|

1:12-1:16 |

maximum 30" high, 30' long |

|

1:16-1:20 |

Maximum 30" high, 40' long |

|

Cross Slope |

Maximum 1:50 |

A study done by Wolf et al. looked at the effects of roughness of nine different sidewalk surfaces; six studied over three years and three surfaces added in the last year. Wolf et al. compared poured concrete (control) to different types of brick sidewalks. They varied in composition (Concrete, Clay), spacing (bevel size, no bevel) and degree of herringbone placement (45, 90) as shown in Table 2. Sidewalks were installed by an Interlocking Concrete Pavement Institute (ICPI) certified contractor. Ten nondisabled subjects were recruited over the three year period. Accelerations were recorded on the seat and footrest of the chair as the subjects drove over the surfaces. They concluded that for manual WCs, the 90 degree surfaces with 0 and 2mm bevels resulted in significantly lower WBV than the standard poured concrete surface. For power WCs, the 90 degree surface with no bevel resulted in significantly less WBV at the seat and the 90 degree surfaces with 0, 2 and 4mm bevels resulted in significantly less WBV at the footrest than the poured concrete surface. The results also showed that the 90 degree surface with an 8mm bevel had the highest WBV while the 90 degree surface with no bevel resulted in the lowest WBV. The fact that the poured concrete surface resulted in significantly higher vibrations than some brick surfaces was most likely caused by the large gaps between the slabs of concrete. (Wolf et al, 2007)

Table 2: Specifications of Surfaces Tested

| Dimension (mm) | |||||||

| Surface | Name | Edge Detail | Compo-sition | Length | Width | Height |

Installed Pattern |

|

1 |

Poured Concrete |

— |

Concrete |

— |

— |

— |

Smooth |

|

2 |

Holland Paver |

Square (no bevel) |

Concrete |

198 |

98 |

60 |

90° |

|

3 |

Holland Paver |

2 mm bevel |

Concrete |

198 |

98 |

80 |

90° |

|

4 |

Holland Paver |

8 mm bevel |

Concrete |

198 |

98 |

60 |

90° |

|

5 |

Whitacre-Greer |

4 mm bevel |

Clay |

204 |

102 |

57 |

45° |

|

6 |

Pathway Paver |

Square (no bevel) |

Clay |

204 |

102 |

57 |

45° |

|

7 |

Holland Paver |

6 mm bevel |

Concrete |

198 |

98 |

60 |

90° |

|

8 |

Holland Paver |

6 mm bevel |

Concrete |

198 |

98 |

60 |

45° |

|

9 |

Holland Paver |

4 mm bevel |

Concrete |

198 |

98 |

60 |

90° |

Another study conducted on 6 of the same surfaces (Poured concrete; 90 degree with 0, 2, and 8mm bevels; 45 degree with 0 and 4mm bevels) showed that for power WCs traveling at a speed of 1 m/s, the ISO 2631 limit for an 8-hour exposure to vibrations was exceeded by the 90-degree, 8mm bevel surface and the 45-degree, 4mm bevel surface. At a speed of 2 m/s the exposure limit would be exceeded in less than 3 hours of continuous driving on all surfaces. (Cooper et al, 2004) While WC users do not typically drive continuously for 3 hours, they do travel above 8 hours a day on average and experience some amount of vibrations during all movement. (Tolerico, 2006)

To see the extent of whole body vibration exposure that WCs users feel during a typical day, Garcia-Mendez, et al. conducted a study on health risks of vibration exposure to WC users in the community. By attaching vibration data loggers, wheel encoders and seat occupancy sensors to manual WCs, they were able to record vibrations on the WC for two weeks while the users were at a national WC event and at home in their community. The results showed that all of the participants were exposed to vibration levels at the seat surface that were within or above the health caution zone set by the ISO 2631-1 standard. (Garcia-Mendez, 2012)

User Comments/Questions

Add Comment/Question