Anthropometry of Wheeled Mobility Project: Final Report

Prepared for the U.S. Access Board

December 31st, 2010

Center for Inclusive Design and Environmental Access (IDeA)

School of Architecture and Planning

University at Buffalo

The State University of New York

Buffalo, NY 14214-308

Credits

Authors

Edward Steinfeld, Arch.D. Co-Project Director

Victor Paquet, Sc.D. Co-Project Director

Clive D’Souza, M.S. Research Assistant

Caroline Joseph, M.Sc.A. Research Assistant

Jordana Maisel, M.U.P. Research Associate

Graphics

Jonathan White, M.Arch. Research Intern Architect

Heamchand Subryan, M.A., M.Arch., Research Design Associate

Funding for this project was provided by:

U.S. Access Board

National Institute for Disability and Rehabilitation Research, U.S. Department of Education

Acknowledgement

The authors would like to thank the following people for their foresight in perceiving the value of this work:

William Peterson, RERC Project Manager at NIDDR who perceived the need for the project and insured that it was part of the RERC on Universal Design’s mission.

Katherine Seelman, Director of NIDRR during the time the project was conceived.

Lois Thibault, Research Director of the U.S. Access Board who saw the value of continuing the work.

Lawrence Roffee and David Cappozi, Executive Directors of the Access Board during the project period.

Marsha Mazz, Director, Office of Technical and Information Services, who managed the project for the U.S. Access Board when Lois Thibault retired.

Disclaimer

This report was developed with funding from the U.S. Access Board (contract # TPD-ABA-07-C-001). The research was initially funded by the National Institute on Disability and Rehabilitation Research (NIDRR), U.S. Dept. of Education (grant ). The contents of the report do not necessarily represent the policy of the U.S. Access Board or NIDRR, and readers should not assume any endorsement by the Federal government.

Contact Information

For further information, contact:

Edward Steinfeld, Director

Center for Inclusive Design and Environmental Access (IDeA Center)

School of Architecture and Planning

University at Buffalo

3435 Main Street, 378 Hayes Hall

Buffalo, NY 14214-3087

716.829.5899 (phone)

arced@buffalo.edu (email)

This document is available free of charge from the IDeA Center website at: http://www.udeworld.com/anthropometrics

© Copyright, Center for Inclusive Design and Environmental Access, 2010

Unlimited use of this document for educational and research purposes are permitted without written permission but altering the contents and distribution for sale is not allowed without prior written permission from the IDeA Center.

Executive Summary

Anthropometry is the study of human body characteristics and abilities. Wheeled mobility devices (WhMDs) that are used by people with disabilities include manual wheelchairs, power chairs and scooters. Standards for accessible design include many requirements based on the anthropometry of WhMD users. Key requirements apply to clear floor area, knee and toe clearances, maneuvering clearances, reach limits, grip force requirements and door usability factors. Reference information is also often included on the characteristics of mobility devices like illustrations and dimensions of unoccupied or occupied wheelchairs. This reference information often forms the basis of requirements like clear floor area. Thus, they are as important as the requirements themselves.

The anthropometric data on WhMD users that underlies the technical requirements of the ICC/ANSI A117.1 (1998) Accessible and Usable Buildings and Facilities (ICC/ANSI) were generated from research completed from 1974 −1978 using a research sample that included about 60 individuals who used wheelchairs (see Steinfeld et al., 1979). In 1982, the U.S. Access Board developed the first Federal guidelines for facility accessibility in the U.S. Under the Americans with Disabilities Act of 1990 (ADA), the Board continued this work, publishing the ADA Accessibility Guidelines (ADAAG) in 1991 which were updated in 2004 by the ADA and ABA Accessibility Guidelines for Buildings and Facilities (ADA-ABA Standards). The latter was adopted in place of the ADAAG by the Department of Justice in 2010. Provisions for WhMDs in both guidelines were largely derived from the research conducted in the 1970’s (Steinfeld et al., 1979). Research in other countries, comments from the public, and demographic, social and technological trends indicate that there is a need for new current information on the anthropometry of WhMD users to bring standards up to date. Recognizing this need, the National Institute on Disability and Rehabilitation Research initiated a research study through the Rehabilitation Engineering Research Center on Universal Design at the IDeA Center, University at Buffalo, SUNY, to obtain the needed information in 2000. The initial research activities developed new anthropometric measurement methods and collected data on over 200 WhMD users. In 2006, the U.S. Access Board funded this project to expand the database and develop it further.

This report documents the research conducted at the IDeA Center from the initiation of the project in 2000, including analysis of data on a sample of almost 500 individuals who use WhMDs. Our findings are compared to those in three other countries and to the current standards in all four countries. Many differences exist in both the standards and research studies. Although details of the research results differ from study to study, trends in the data support the need to make many important revisions to the U.S. standards. This report provides a description of the research, an analysis of the results and a discussion of the implications.

The research included the collection of demographic information and WhMD characteristics, and the measurement of structural and functional anthropometry. The demographic and WhMD characteristics were recorded for approximately 30 variables using a checklist, along with digital still photographs of each WhMD user. The structural anthropometric measurements required the measurement of the body and devices size at rest. The methods incorporated the use of a 3-dimensional (3-D) digitizing arm that allowed us to capture the location of body and device landmarks in three dimensions. This technology provided data that we used to develop static 3-D human models. Conventional structural and functional measurements can be also be derived from the 3-D information. The functional anthropometric measurements required measuring reaching ability, grip strength and the minimum space needed for turning. Reaching performance was measured in 3-D with the digitizing arm; grip strength was measured with conventional hand dynamometers; and maneuvering was measured through systematic measured observations of performance and video analysis. We also measured performance during door use tasks via the use of observational rating scales.

We selected measurement variables and procedures for measurements that were based on advice provided by experts in anthropometry and ergonomics, human modelers, architects and designers, and clinicians. Preliminary studies were completed at the University at Buffalo, SUNY to assess and demonstrate the accuracy and reliability of the measurement method. Focus groups with WhMD users were also conducted to ensure that the protocols for the research, which involved intimate contact with the body, were acceptable to the participants. Institutional Review Board approval for the research activities, including recruitment methods and confidentiality, was obtained at three universities.

Software was developed to facilitate expansion of the database and data collection at multiple sites. This software included quality assurance routines to identify errors in datasets and routines to merge other data sets into the database. Most of the research participants came from the Buffalo metropolitan area. But, two other research sites were contracted to provide data during Anthropometry of Wheeled Mobility the research activities to increase the diversity of the overall sample, test the software and test the feasibility of sharing methods. The expansion of the database was quite successful. Thus the database can be augmented over time with new data collection activities.

Data were collected for a total of 495 WhMD users to ensure a diverse sample of WhMD users: Buffalo and its suburbs (n=351), Pittsburgh (n=100) and Ithaca (n=44). The quality assurance software was used to check the quality of the 3-D data collected at each of the sites. All of the acceptable demographic, WhMD and anthropometric information was compiled in a database.

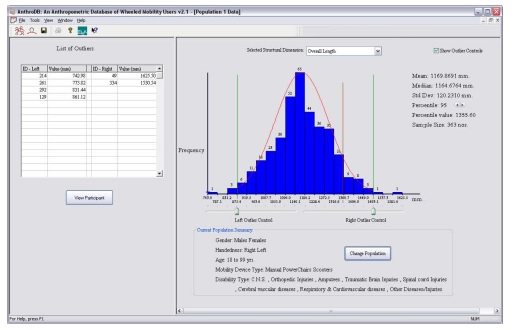

Prototype software was developed to allow designers and standards developers to access the data using a graphical interface. For example, a user can set parameters for width of occupied device and identify the extent of participants accommodated. Menus also provide the ability to display frequency distributions and percentile data for each variable and to access case data. Menu driven settings enable the user to select different groups for analysis, e.g. males or females, to compare the results.

Although the interactive database provides a significant resource for researchers and standards developers, our dissemination activities and other research demonstrated that this tool is unlikely to be utilized by most designers, particularly architects, interior designers and landscape architects. Thus, we also developed information tools in the form of graphic representations of the results that are more consistent with reference materials these professionals utilize in practice. These tools are available on the IDeA Center’s website under design resources (http://udeworld.com/dissemination/design-resources.html). An online educational module has also been completed to explain the research and introduce these design tools to professionals.

This report includes results of analyses of data on the basic aspects of wheeled mobility anthropometry. The topics covered include: selected dimensions of unoccupied and occupied devices, knee and toe clearance, reaching abilities, gripping strength and turning spaces. We also completed a study on the usability of several doors for a sub-sample of our participants. This study provides information on the effectiveness of current standards in meeting the needs of WhMD users.

Dissemination activities included the publication of 8 refereed journal articles, 24 refereed conference papers and one encyclopedia article. Standards development activities have been Anthropometry of Wheeled Mobility initiated with four standards development organization in the U.S., Canada and Ireland. An online self-instructional course on the research has been completed and is now available for the public. A textbook on universal design, under contract with a major commercial publisher, is under development and will include a section describing the research and its implications.

The key findings of the research are:

1. Sample composition: There are important differences in the sample based on recruitment methods. This emphasizes the importance of multi-site studies for this population.

2. Diversity: There are often large differences in the body and chair sizes and in the functional abilities of manual chair, power chair and scooter users, and men and women.

3. Measurement parameters: There are no generally accepted and shared definitions of variables for both anthropometric research and standards development, which impedes integration of research and practice.

4. International comparison: Different countries use different approaches to developing standards based on anthropometry. None of the standards reviewed had a comprehensive and explicit approach to evidence based practice.

5. Landmarks: Some dimensions in standards do not correspond to clear measurement landmarks on the body and device, creating barriers in translating research findings to standards development.

6. Reference WhMD: The U.S. standard reference wheelchair does not represent the sizes of unoccupied wheelchairs in our sample well. Contemporary wheeled mobility devices are much more diverse in size and features than the reference wheelchair.

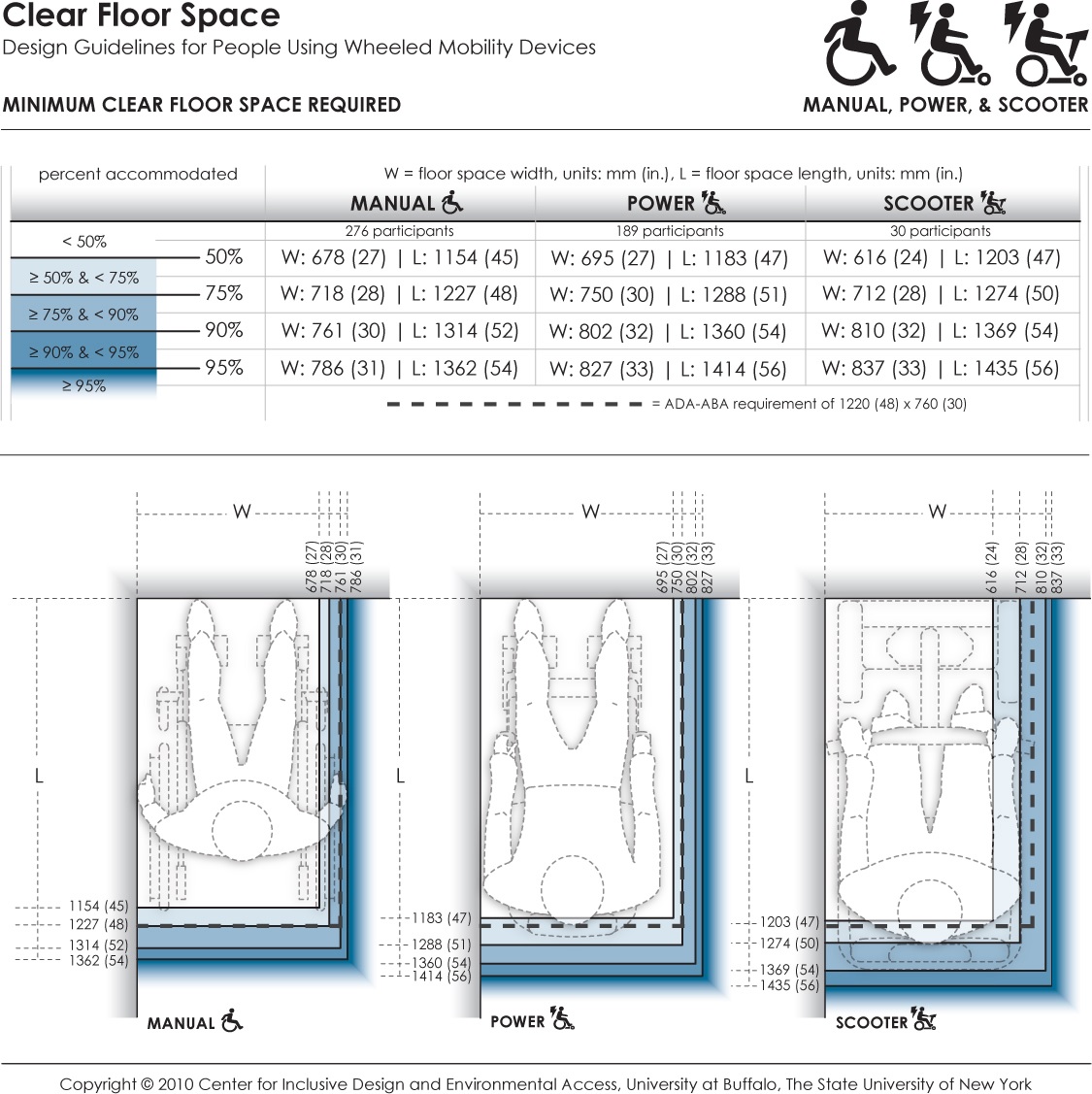

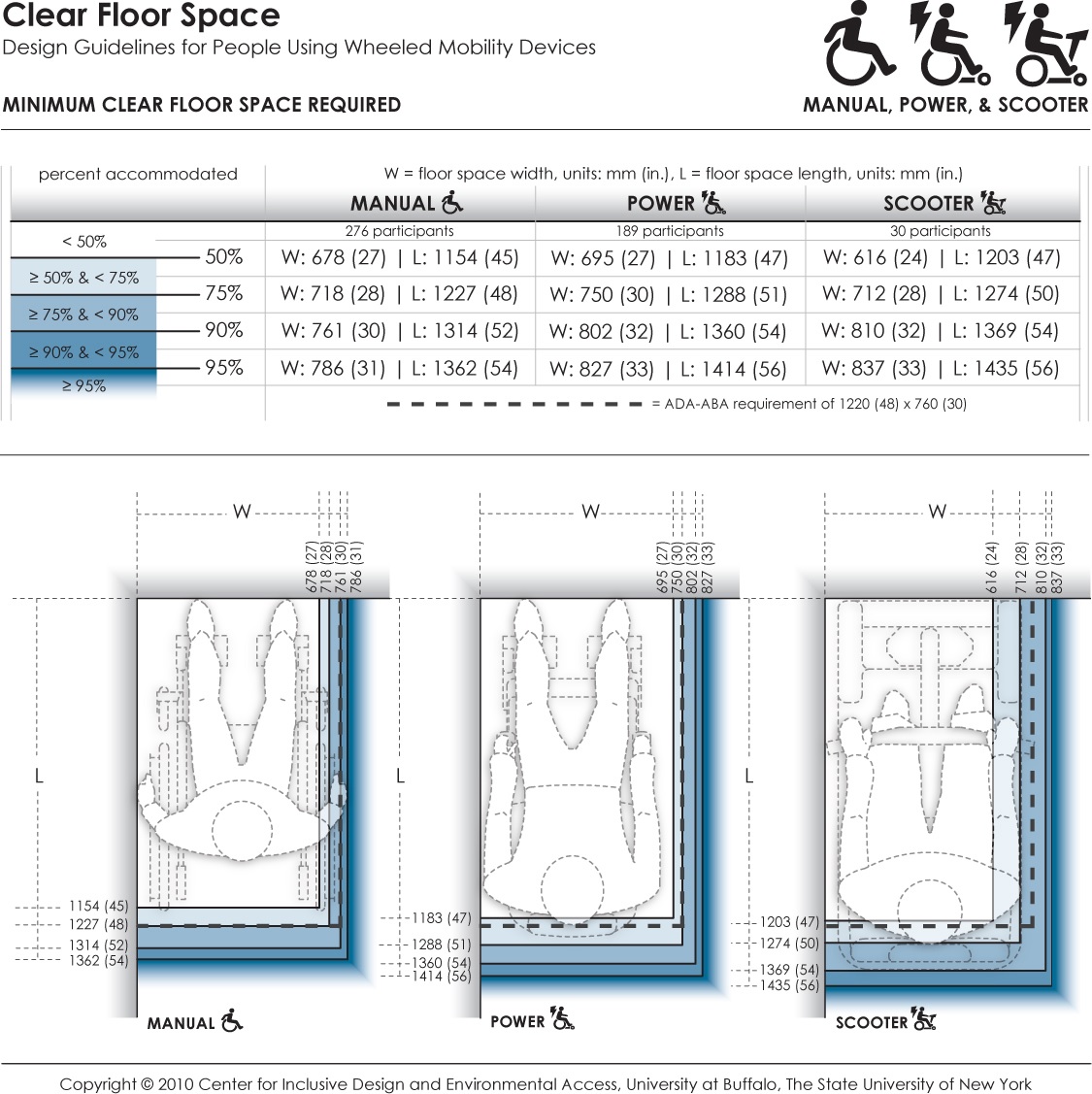

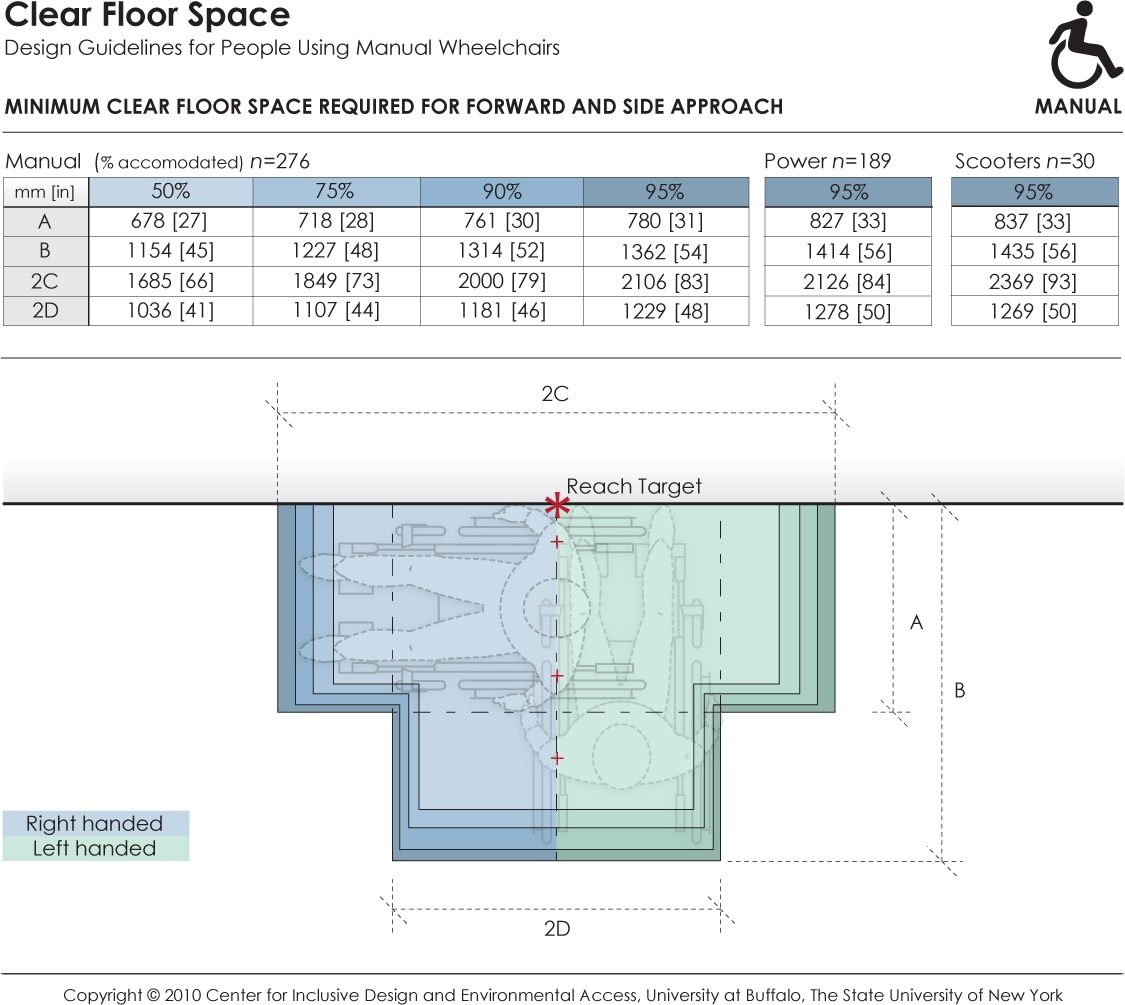

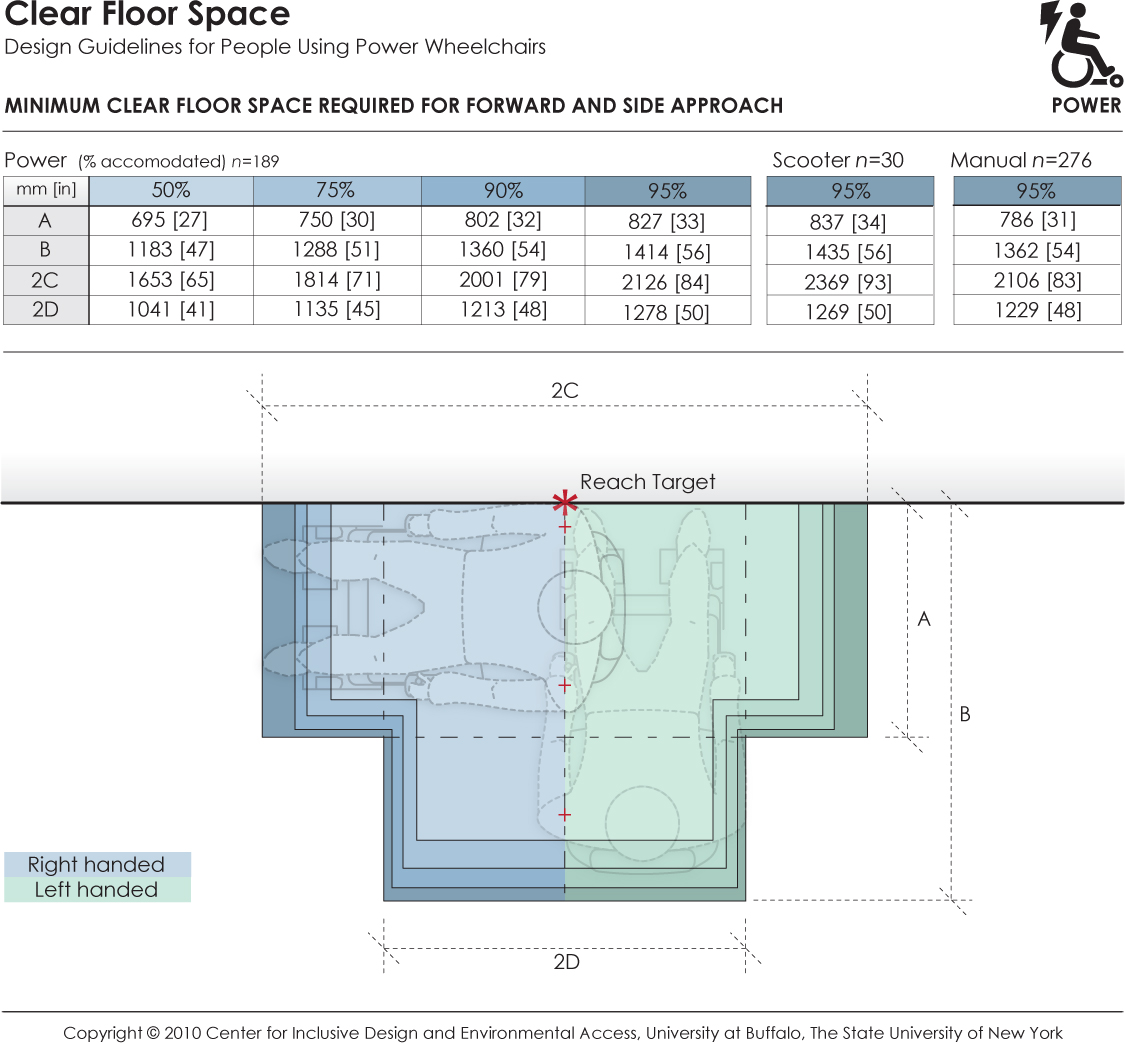

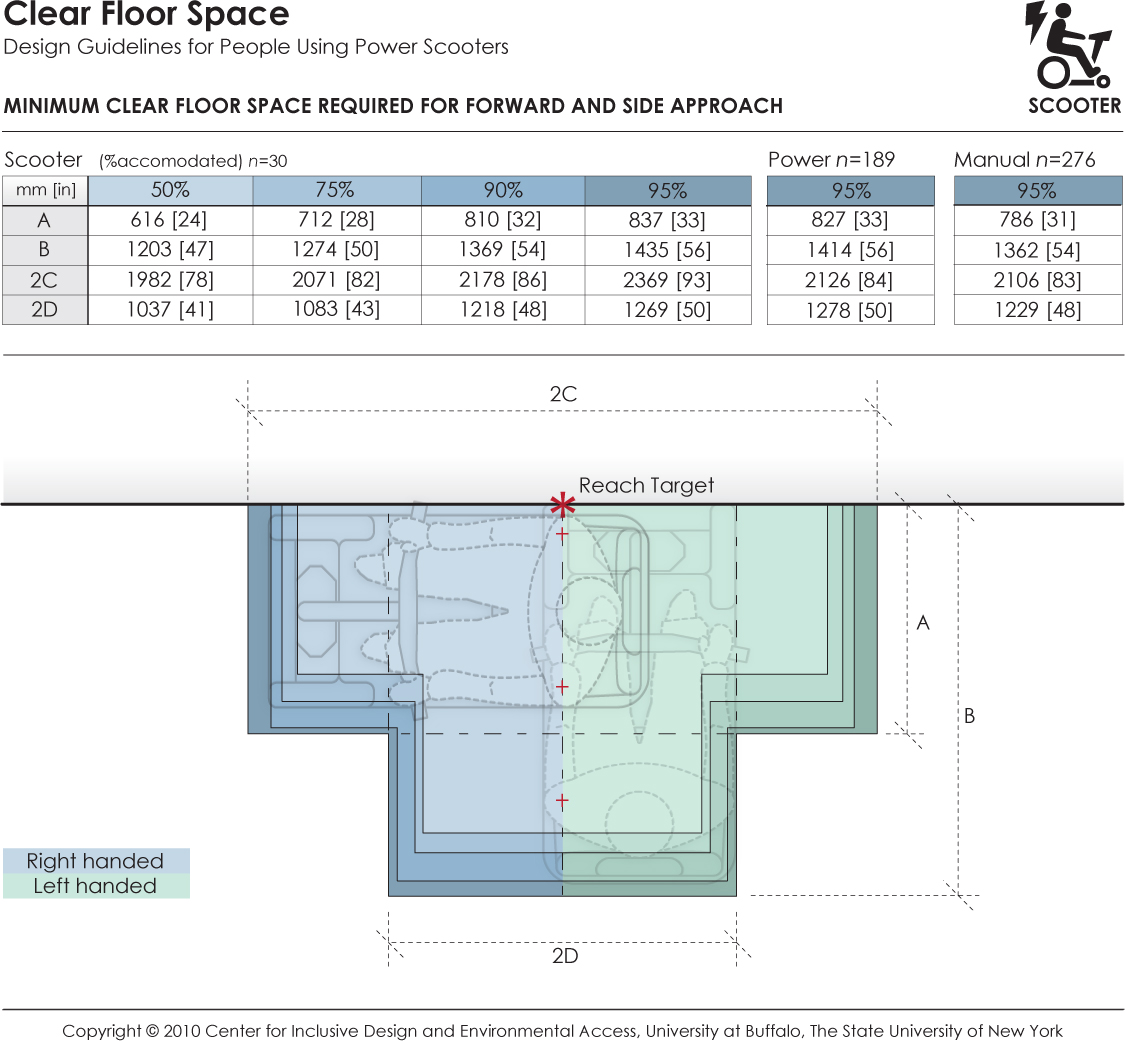

7. Clear floor space: A large minority of participants in our research would not be accommodated by the current U.S. standard for clear floor space, especially for length. The people excluded include those who use any of the three types of WhMD. Other countries have already increased the clear floor space used in their standards.

8. Seat height: Seats for a majority of our sample have seat heights above that shown in the reference wheelchair in the U.S. standard, especially the power chairs and scooters.

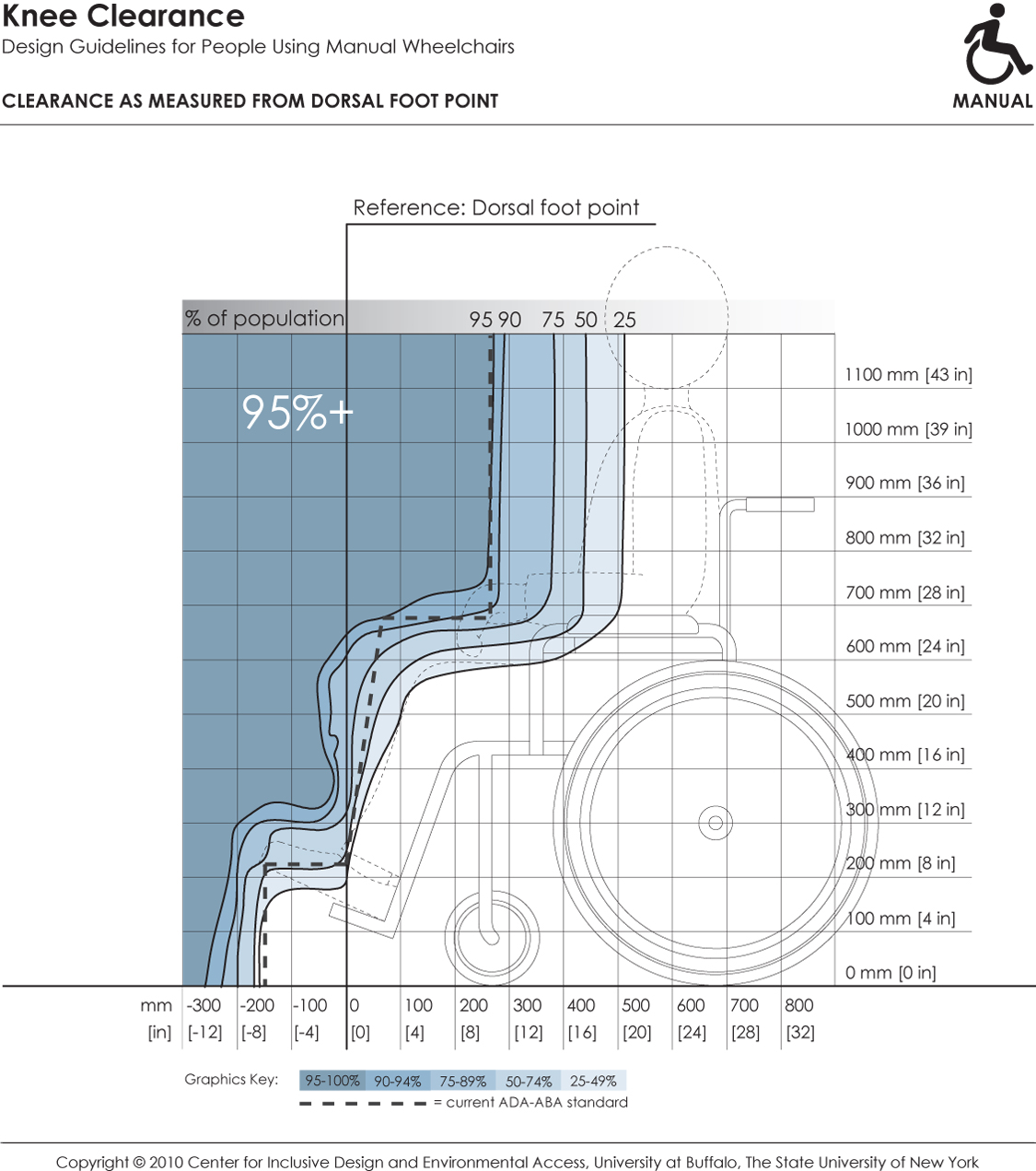

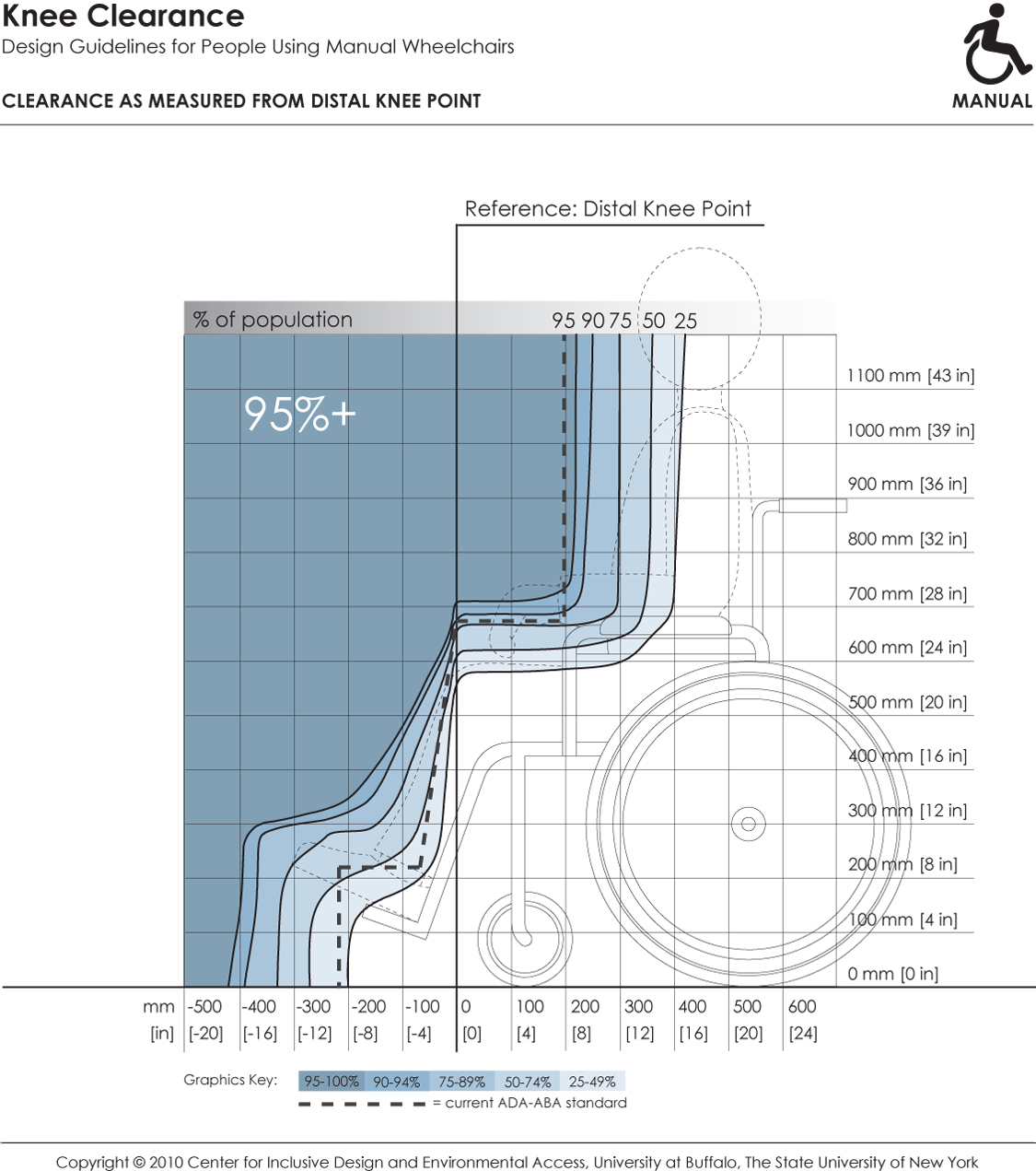

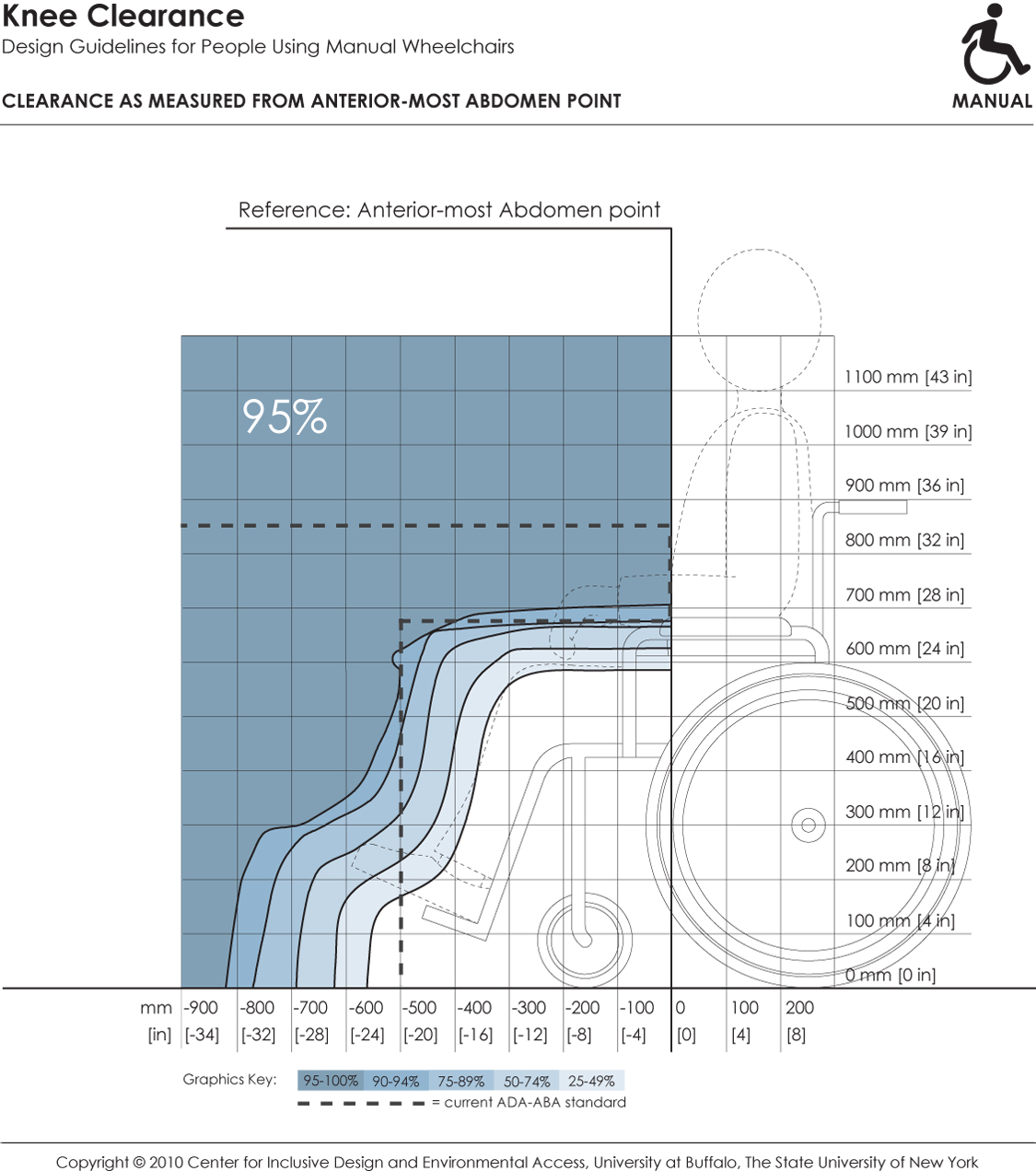

9. Knee and toe clearances: The current U.S. standards for knee and toe clearances do not accommodate a majority of participants in our sample.

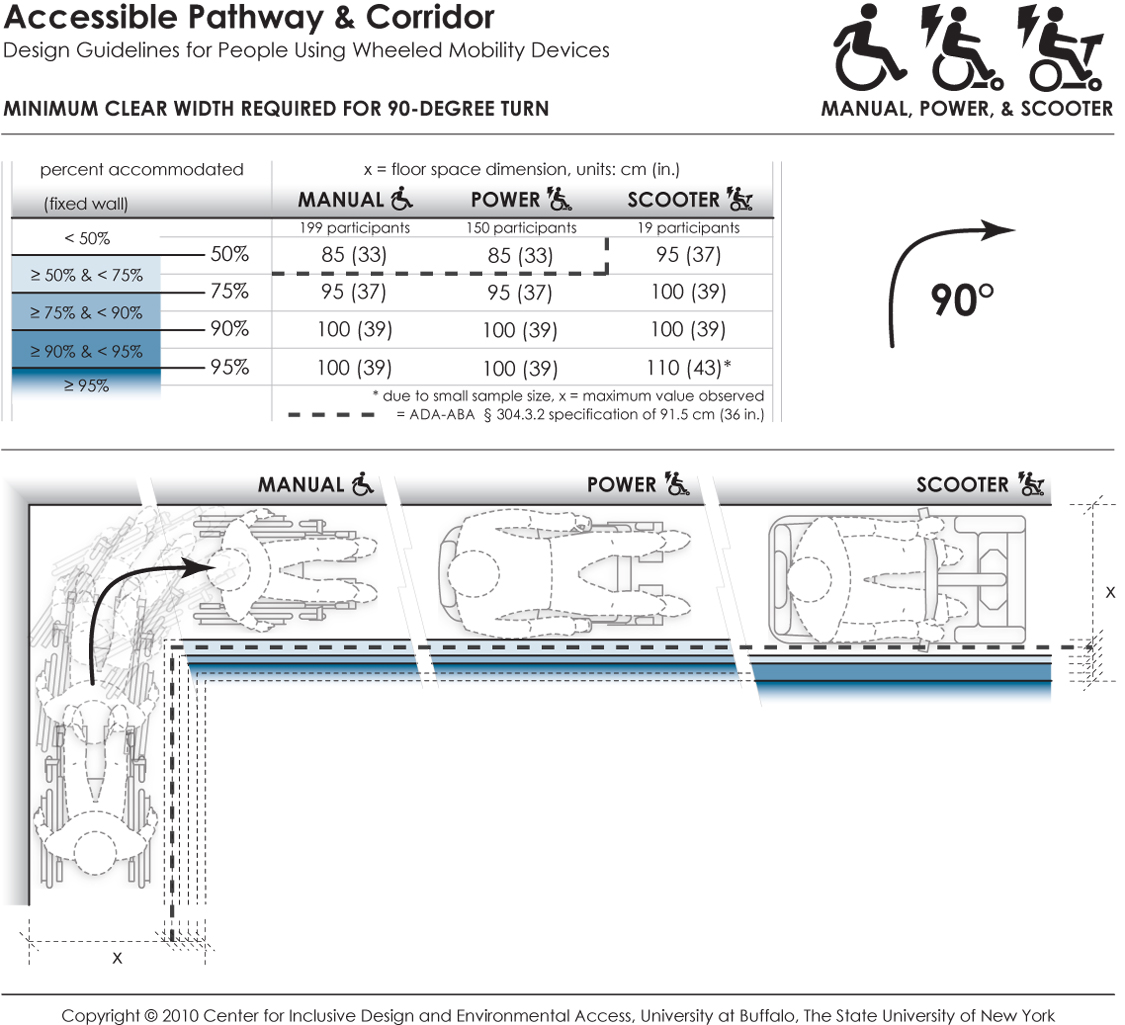

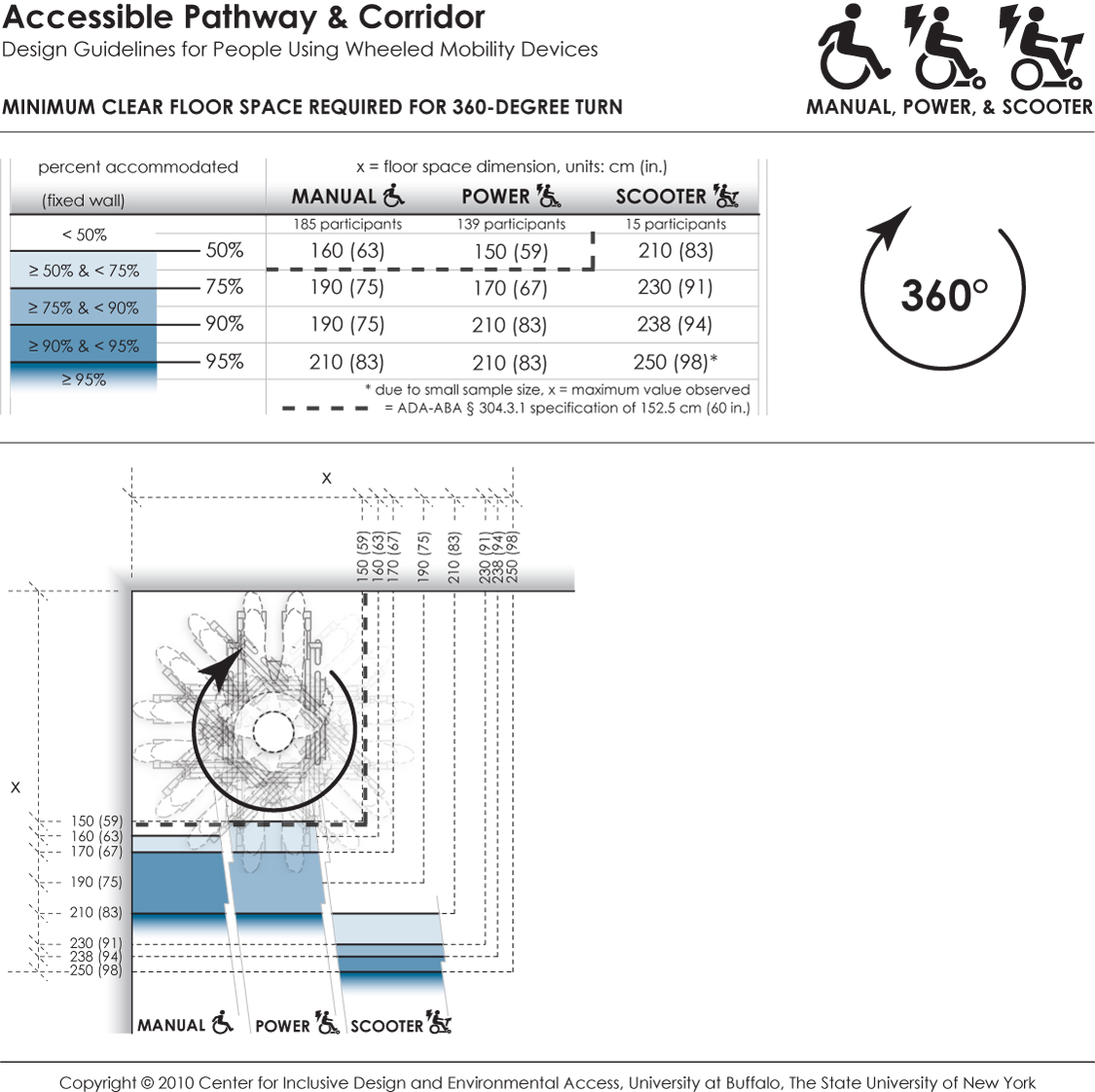

10.Maneuvering clearances: A significant proportion of WhMD users, scooter users in particular, are not accommodated by current maneuvering clearances in U.S. standards, although the proportion differs for different clearances. In particular, the current standards do not accommodate most of our sample for completing a 360-degree turn. There are also a small number of participants in all categories who require much larger clearances than current standards provide.

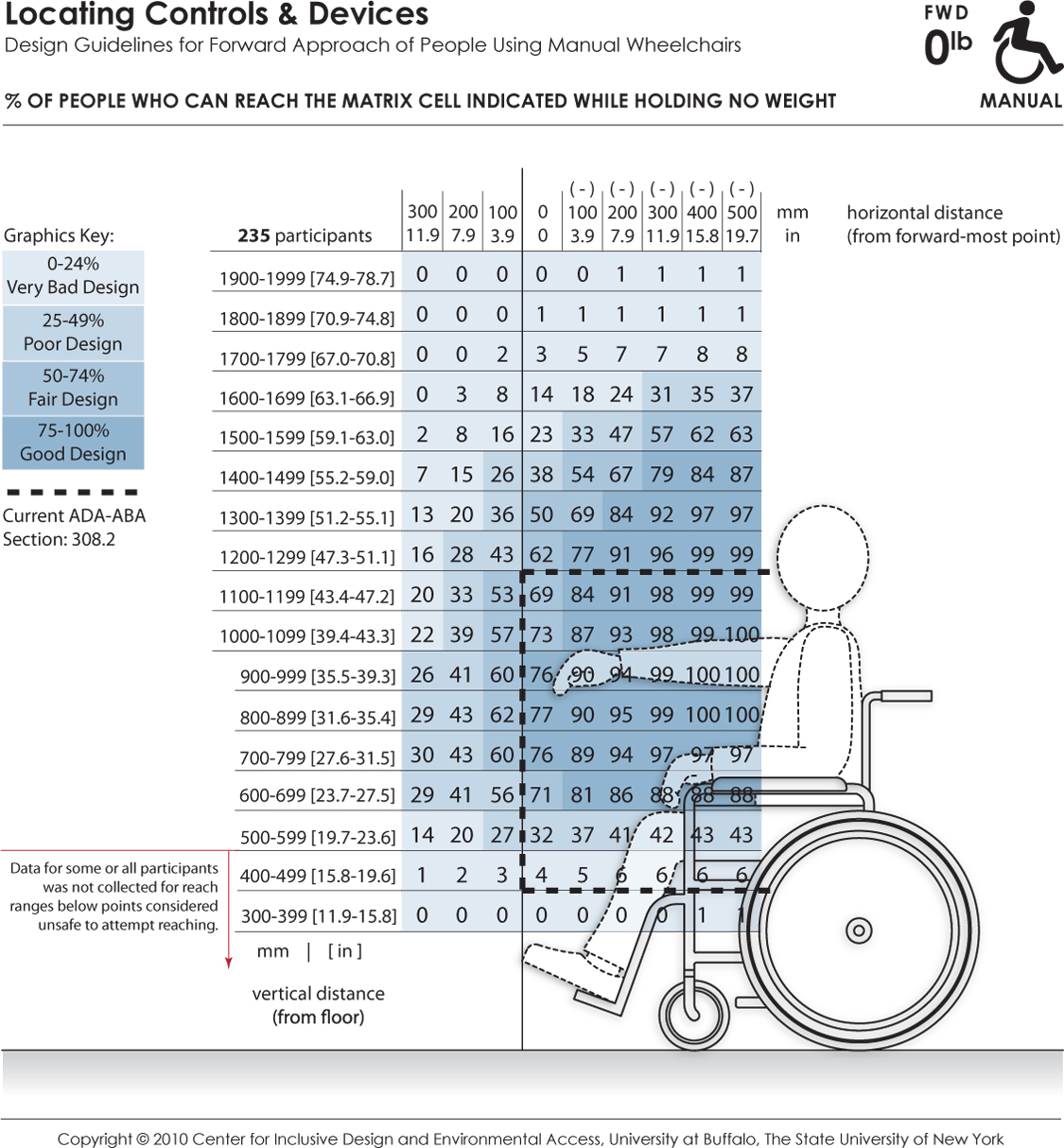

11. Reaching ability: A significant percentage of WhMD users have very limited functional reaching abilities.

12. Reach limits: A majority of WhMD users cannot complete a forward reach to the minimum forward reach height in U.S. standards on a vertical plane in front of their anterior most point (toes or device). The current high side reach limit accommodates WhMD users. The low reach limit, as defined, is currently inappropriate for safety reasons.

13.Operating forces: The maximum operating force in the current standards is too high for the majority of WhMD users.

14. Door usability: The usability study confirmed many of the existing clearance requirements for doors but also identified the need for improving some others, especially the door clearance width. Findings support the increased use of automated doors and the development of improved closer technologies.

The research findings highlight the importance of integrating research with standards development, organizing research collaborations and the need to develop standardized research methods. Now that a foundation of tools and procedures has been developed and extensively tested for systematic scientific research in this field, the cost of implementing future research using these methods is significantly reduced.

There is still much knowledge to be gained from further analysis of the data collected. We intend to continue to analyze and publish the results of this work. We will continue to reach out to human modeling software companies to augment their databases of ambulant people with our database of WhMD users. The research team anticipates the development of future research collaborations, dissemination activities and standards development initiatives to advance the work that has already been completed.

1.0 Background

Relevance

The standards used to ensure accessibility for people who use wheeled mobility devices (WhMDs) like wheelchairs and scooters are based on research in anthropometry, the measurement of body sizes and physical abilities. The anthropometric data on WhMD users that underlies the technical requirements of the ICC/ANSI A117.1 (1998) Accessible and Usable Buildings and Facilities (ICC/ANSI) were generated from research completed from 1974 −1978 using a research sample that included about 60 individuals who used wheelchairs (see Steinfeld et al., 1979). In 1982, the U.S. Access Board developed the first Federal guidelines for facility accessibility in the U.S. Under the Americans with Disabilities Act of 1990 (ADA), the Board continued this work, publishing the ADA Accessibility Guidelines (ADAAG) in 1991, which were updated in 2004 by the ADA and ABA Accessibility Guidelines for Buildings and Facilities (ADA-ABA Standards). The latter was adopted in place of the ADAAG by the Department of Justice in 2010. Provisions for WhMD users in both guidelines were largely derived from the research conducted in the 1970’s (Steinfeld et al., 1979). Comments from people who use powered mobility devices indicate that increases in space and maneuvering requirements and decreases in reach ranges are needed in the Board’s guidelines to accommodate the use of such devices, which are generally larger, heavier, and less finely maneuverable than manual wheelchairs. Since the 1970’s, research on the anthropometry of WhMD users has been conducted in Australia, the United Kingdom (U.K.) and Canada. All of those countries have revised or are revising their standards based on that research.

In 30 years, many changes have occurred in nature of the U.S. population, the characteristics of people who use WhMDs and the characteristics of equipment that they use. Many more power chairs are in use now than in the 1970’s. Significant advances in wheeled mobility technology,health care, public health and demography have occurred that impact the body sizes and functional abilities of those who use wheeled devices for mobility. For example, power wheelchairs and scooters are often larger in size than manual chairs. In addition, improved health care technology has allowed people with more serious disabilities to survive longer than in earlier decades. These individuals may have conditions that affect their abilities to maneuver devices in small spaces or reach objects. A significantly broader range of devices is now available, from highly-adjustable battery-powered wheelchairs to 3- and 4-wheeled scooters with front tillers. Anthropometry of Wheeled Mobility Scooters also are growing in popularity. Yet, the technical requirements in U.S. standards have not changed. It is likely that the current U.S. standards do not reflect the actual dimensions and abilities of contemporary WhMD users.

Very few studies of the anthropometry of WhMD users were conducted in the 1980s and 1990s, especially in the U.S. In response to this lack of current information, the IDeA Center, with funding from the National Institute on Disability and Rehabilitation Research, developed a new set of anthropometric measurement methods and a comprehensive anthropometric data set of over 200 WhMD users was created (Feathers et al., 2002, 2004; Paquet and Feathers, 2004; Steinfeld et al., 2005). Rigorous scientific procedures were used in the development of the research methods and new software was created to organize and analyze the results. While much was accomplished in that study, there were important research needs that were unmet. First, a larger sample was needed to provide a more accurate characterization of the anthropometry of WhMD users. Second, a more diverse sample in terms of ages and WhMD technologies was needed to help improve the representativeness of the sample. Third, new dissemination products were needed to help ensure that the research findings could be translated to design practice and standards development.

Additionally, comparisons of international standards and research were needed to assess the adequacy of the current U.S. accessibility standards and help set priorities for improving regulations. Comparisons are also useful to identify best practices and differences related to cultural factors. Thus, in addition to collecting anthropometric data, we also completed a comparative analysis of research and standards on wheeled mobility in the U.S., the U.K., Australia and Canada. The analysis was limited to WhMD dimensions, minimum clear floor areas, space requirements for maneuvering, knee and toe clearances, and reach limits.

Objectives

The objectives of this study, supported by the U.S. Access Board were to:

1. Collect data on an extended sample with a target of a total of 500 individuals.

2. Collect and compare anthropometric research studies on wheeled mobility in Canada, the U.K. and Australia, with the U.S. standards and the research results from the current study.

3. Develop dissemination products including a final research report, tools for using the database and an online educational module.

The scope of the research analysis was limited to key anthropometric issues in accessibility standards:

-

Unoccupied device width and length

-

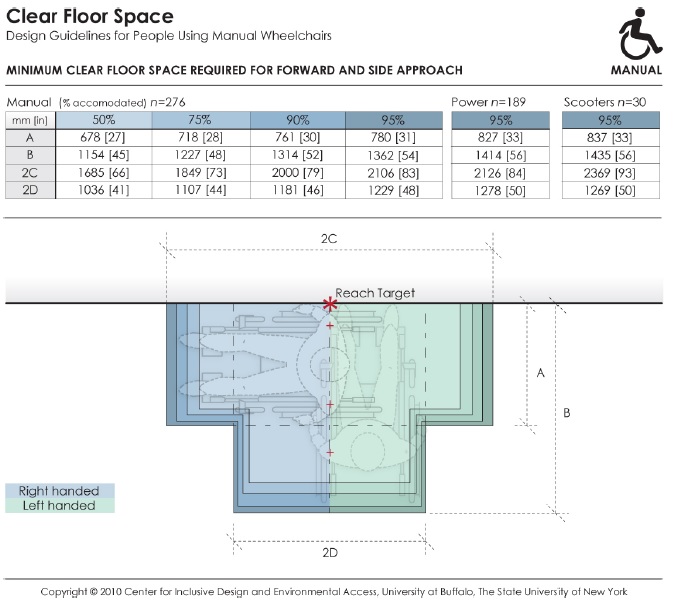

Clear floor space, or occupied footprint

-

Seat height*

-

Knee and toe clearances:

-

Knee height and depth

-

Toe height and depth

-

-

Maneuvering clearances on level surfaces:

-

90-degree turn

-

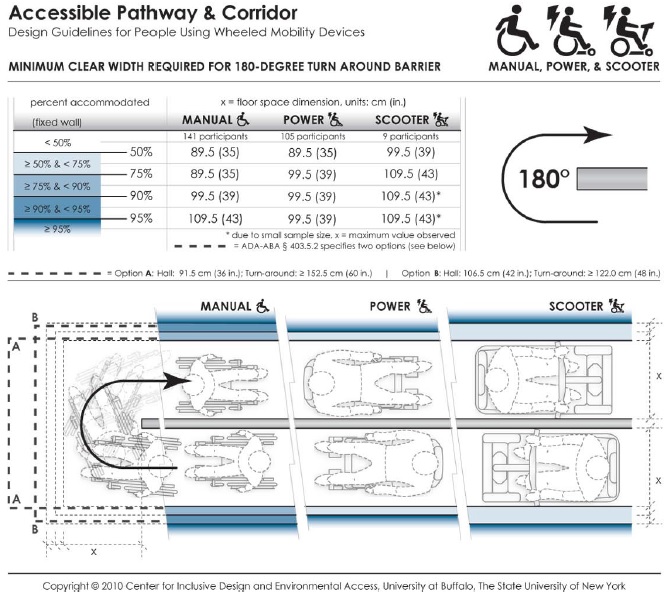

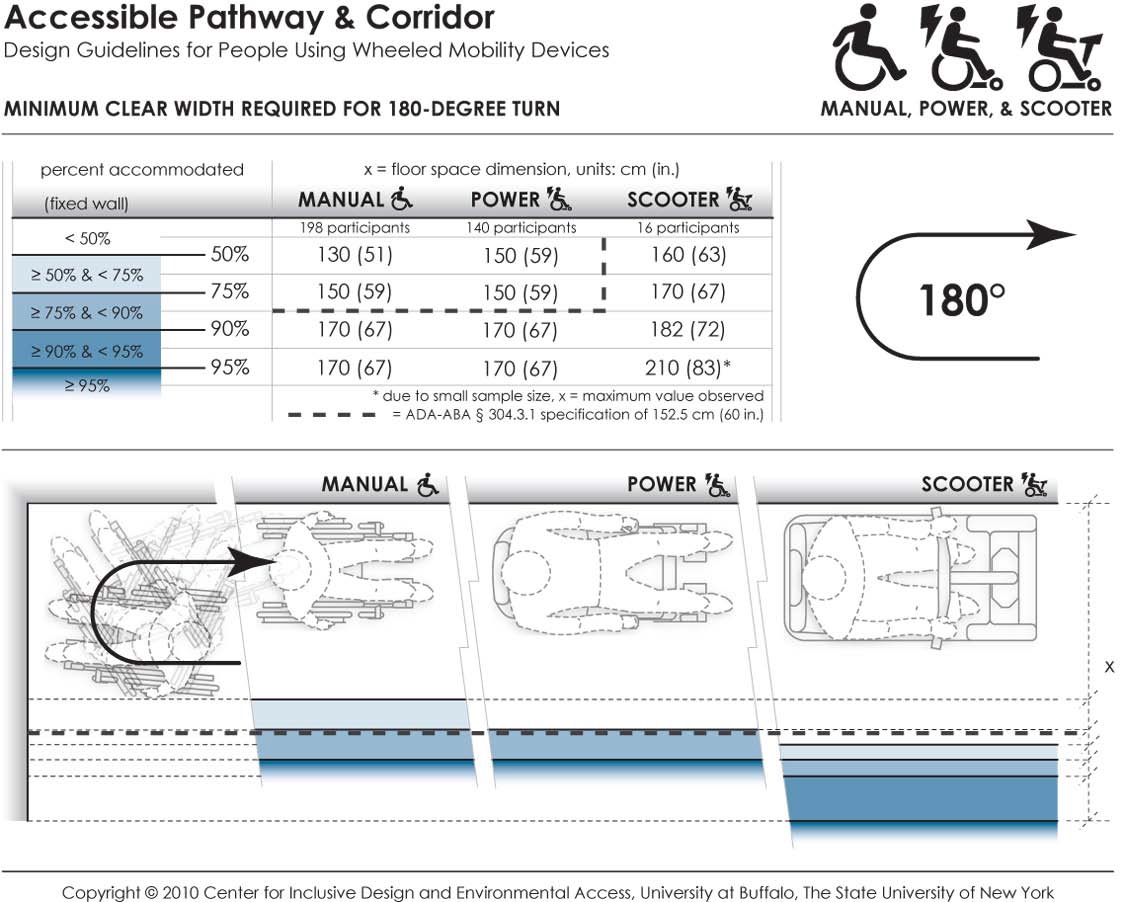

180-degree turn

-

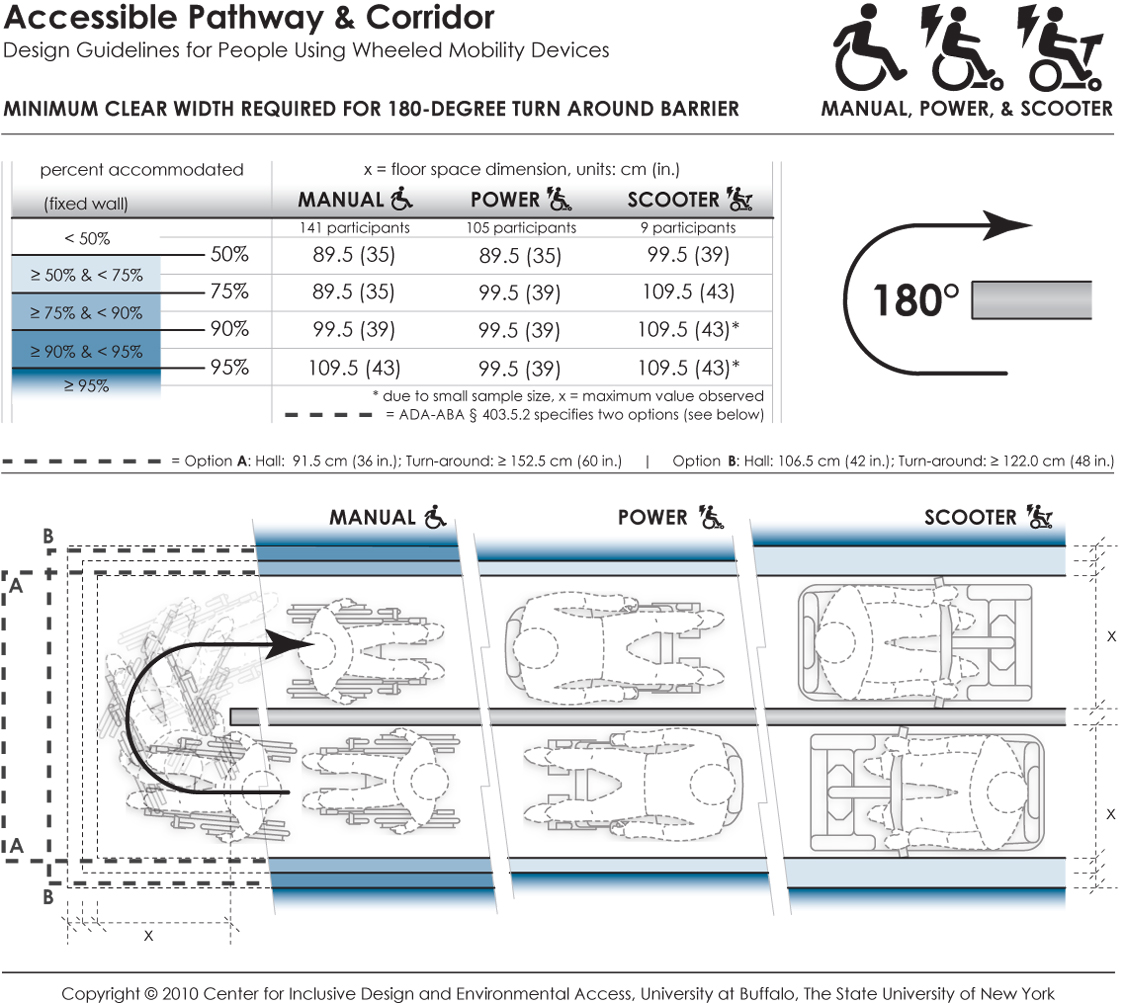

180-degree turn around a barrier*

-

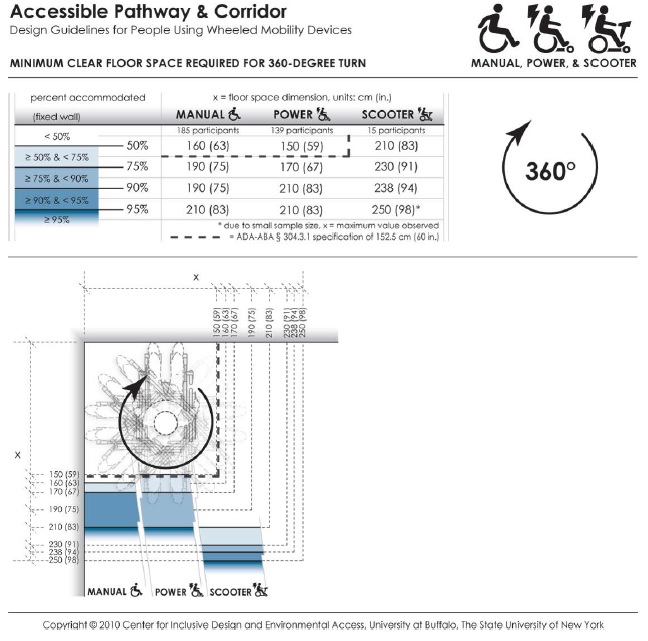

360-degree turn

-

-

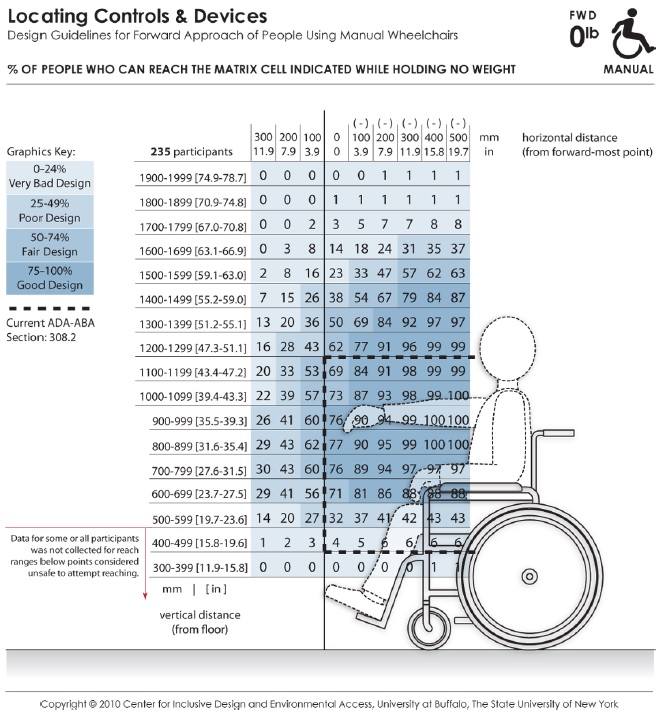

Reach ranges:

-

Forward reach

-

Side reach

-

Side reach over an obstruction

-

-

Grip Forces*

-

Door use

Note, scope items with asterisks were added by IDeA Center.

Report Organization

This report documents the basic findings of the research and compares them to the national standards from the three countries and the U.S. It also compares the research findings to the research underlying the standards of these three other countries. Section 2.0 describes the methods we used to collect the data and make the comparisons. Section 3.0 describes the research results. Section 4.0 discusses the implications of these findings for design and standards development. Section 5.0 describes related dissemination and knowledge translation activities, and Section 6.0 provides some general conclusions, including recommendations for future research and knowledge translation activities. The Appendix includes a list of publications on the project and a set of information tools for designers and standards makers.

Units

The scientific practice of anthropometry is conducted using Metric units. However, in the U.S., accessibility standards are developed in Imperial units. Thus, in this report, we have used Metric units as the primary form for all dimensions. Some tables only have Metric units for space reasons. We included Imperial equivalents in parentheses in the text to assist the reader who is familiar with the dimensions in the standards. The ADA-ABA and other U.S. standards use a “soft’ conversion method in which Metric equivalents are rounded off to the nearest 5 mm except for very small values. Thus, in this report, where we refer to values in the ADA-ABA, we use the soft conversion to avoid confusion with the original source. Elsewhere, including our recommendations for revising the ADA-ABA, we use a “hard” conversion, rounded off to the nearest 1 mm. One exception to the Metric units as primary is in Section 3.0 on grip forces, and these dimensions are reported in pounds-force (lbf) as they were collected.

Text Descriptions

To facilitate comprehension of the report by people who use screen readers, we have included descriptive captions for all figures and tables, alt tags in digital versions and long text descriptions for figures. In Section 3.0, there are graphs of results but, each graph is simply a graphic summary of the data in the accompanying table that appears below it. The tables are readable by screen readers. Thus, there is no need for a further text description of the summary figure since the data is fully accessible to all readers.

2.0 Methodology

2.1 Participant Recruitment and Sampling

A sample of 495 WhMD users was recruited for the study. These included sub-samples of manual wheelchair users, conventional powered wheelchair users and scooter users. We intentionally oversampled powered wheelchair users in order to capture the sizes and space requirements of this group.

It would be useful to know how our sample compares to national estimates of the WhMD population. The most recent published estimates on the type of device are provided by LaPlante and Kaye (2010), and Cooper and Cooper (2003). LaPlante and Kaye (2010) used data from the 1994‒95 National Health Interview Survey on Disability (NHIS-D). More recent data available on the utilization of WhMD’s (e.g. the 2010 U.S. Census Bureau’s Survey of Income and Program Participation) do not distinguish between the types of electric WhMDs. Based on estimates by LaPlante and Kaye (2010), powered wheelchair users and scooter users each comprise about 9% of the WhMD user population not residing in institutions. A representative sample of 495 WhMD users would therefore include only 45 powered wheelchair and 45 scooter users.

In a review on wheeled mobility demographics, Flagg (2009) cites estimates by Cooper and Cooper (2003) on the proportion of mobility devices in the three categories. They estimated powered wheelchairs and scooters each to be about 15% of the WhMDs in use. The estimates by Cooper and Cooper (2003) were based on their own research and experience in the field, and include wheelchairs used in institutional settings like long term care facilities, rehabilitation hospitals and assisted living facilities. In our research, we recruited from assisted living facilities and day care programs for frail older adults but only people who could propel a chair independently were eligible to participate.

Based on this larger estimate, a sample of 495 WhMD users representative of the U.S. in terms types of WhMD used would include only about 74 power wheelchair and 74 scooter users. Even this larger estimate would not allow an accurate characterization of the sizes and functional abilities of these user groups in our study, which we expected to be quite diverse and different than manual wheelchair users.

Our approach allowed us to accurately describe the range of body sizes and functional abilities of conventional powered wheelchair users and manual wheelchair users. A sub-sample of scooter users was recruited to provide us with preliminary anthropometric data for this group but we were not able, despite great efforts, to recruit a large number of scooter users. It should be noted that it is possible to manipulate our current sample with the use of statistical simulation methods to develop samples that representative in terms of device type, age, and gender (Paquet et al., in preparation).

Data were collected in three different locations to help ensure a diverse sample of WhMD users: Buffalo and its suburbs (n=351), Pittsburgh (n=100) and Ithaca (n=44). Researchers at each of these sites were trained in the data collection methods and used the same measurement equipment to ensure consistency in measurement methods across sites.

2.2 Key Measurement Variables and Procedures

We selected measurement variables and procedures for measurements based on advice provided by experts in anthropometry and ergonomics, human modelers, architects and designers, and clinicians.

The measurement variables include the following:

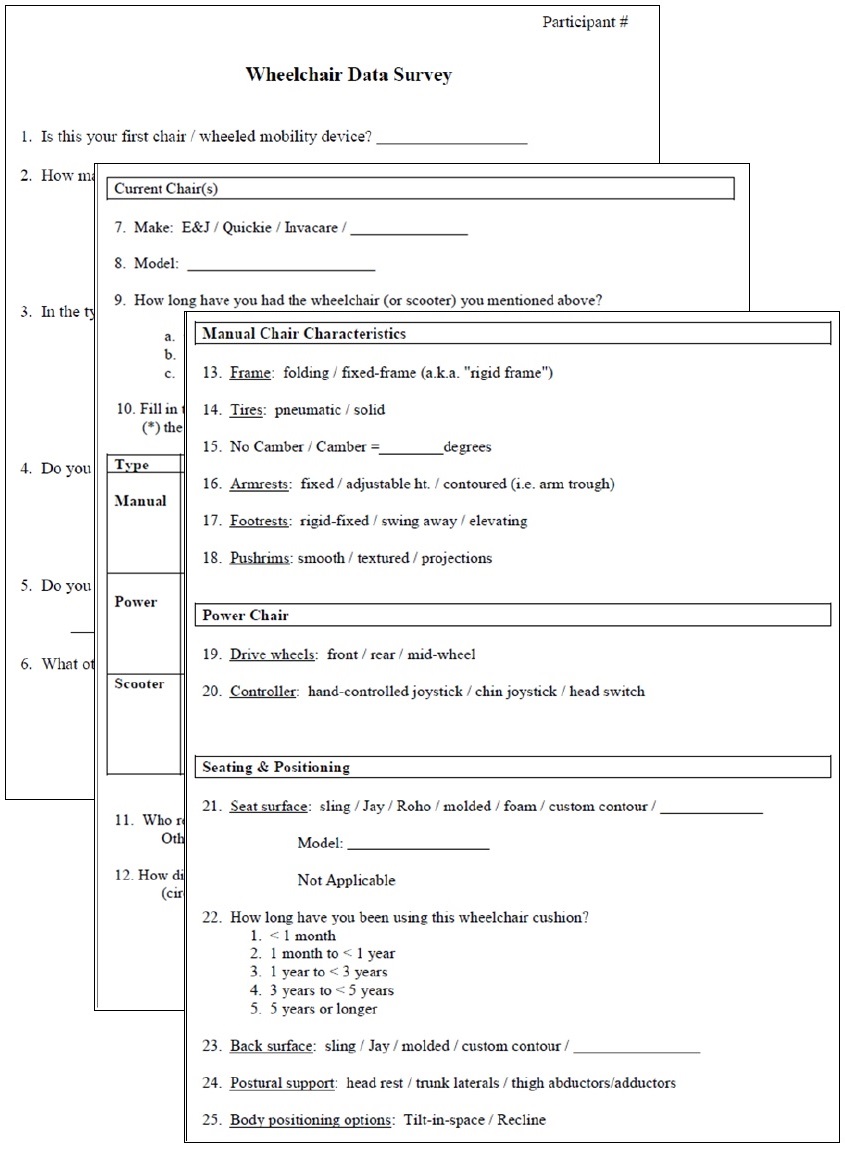

1. Demographic information and wheelchair description: Approximately 30 variables recorded with a checklist, along with digital still photographs of the user and mobility device.

2. Body and wheelchair dimensions: Approximately 125 locations of body and wheelchair points recorded in three dimensions.

3. Reaches and lifts: One-handed maximum reaches recorded at 5 different heights in three different directions for up to four different weight conditions (maximum of 60 reaches total).

4. Maneuverability: Four tasks related to propulsion in confined spaces.

5. Grip Strength: Three repetitions of maximal power grasp recorded for two different upper extremity postures and three repetitions of maximal pinch grip for two types of finger posture (lateral and thumb-forefinger pinches) (12 measurements total).

6. Door use: The level of observed effort was rated as participants used three different doors.

2.2.1 Demographic Information

A survey, checklist and photography were used to capture the demographic and wheelchair characteristics for each WhMD user. Demographic variables included: gender, age, disability status (category), years with the disability, and years using the mobility aid. Key variables associated with the mobility aid included device type (e.g., power chair, scooter), and within each type: make, model, age, armrests, footrests, drive wheels, controller, seat support surfaces and overall condition of the seating surface. A checklist was used to evaluate these device attributes (see Figure 2‒1). Digital photographs of the user and device were taken from the front and side views to document the wheelchair accessories and configurations of WhMD user.

Figure 2-1. Portions of the checklist used to evaluate wheelchair characteristics

2.2.2 Structural Anthropometry (i.e. Body and WhMD Dimensions)

A three-dimensional (3-D) electromechanical probe (i.e. FaroArm, Faro Technologies Inc.) was used to record the 3-D location of body and WhMD device points (Figure 2‒2). The 3-D points were used to estimate body and WhMD heights, widths and depths and to construct static 3-D digital human models of WhMD users.

Figure 2‒2. Data collection with an electromechanical probe allows quick and accurate measurement of the widths, heights and depths of the body and mobility device characteristics.

The 3-D measurements required the measurement of reference points and planes, as well as the measurement of key body and WhMD points with respect to the environment. The IDeA Center has developed a detailed manual that defines each of the points in 3-dimensions, includes illustrations and explains applications for each of the points (Feathers et al., 2004). The reference points and planes, body points and WhMD points, and some of their application are listed in Tables 2‒1 and 2‒2.

Table 2‒1. Wheelchair and environment reference points and planes, and uses.

Table 2‒2. Body points and important anthropometric dimensions associated with each point.

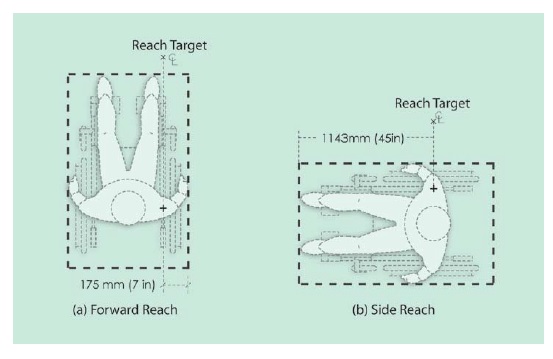

2.2.3 Functional Reach

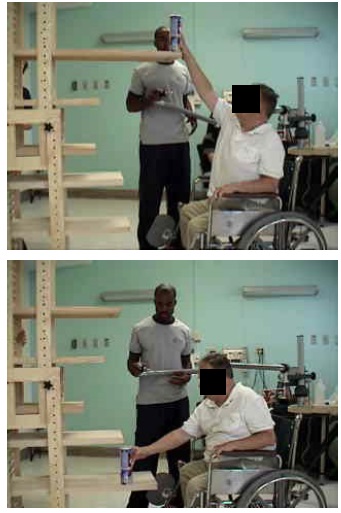

One-handed reach and lift capability data made at different heights, angles and object weights were collected in 3-D. Determining an individual’s 3-D reach envelope required that the reach envelope be measured relative to certain environmental, wheelchair and personal features (e.g. 3-D envelopes measured relative to a point on the floor, forward most portion of a person or wheelchair and/or from a reference point on wheelchair’s arm support surfaces). Data can be presented in 3-D, in the form of 2-D charts along key planes (e.g. sagittal plane to represent forward reach abilities), or described for a standard reach (e.g. maximum forward reach from a reference point).

The one-handed lifting tasks required individuals to move weighted cylinders that were empty or weighted with filler. Cylinders of 75 mm (3 in.) diameter were chosen because they required participants to use one-handed power or lateral pinch grasps, which are commonly used to hold and manipulate products. The size of the cylinders was held constant across conditions and participants. The four weight conditions were no weight, 1 lb, 3 lb and 5 lb.

Those individuals unable to grasp and/or lift any of the cylinders above shoulder height did not complete the reaches. Further, if a particular weighted canister could not be lifted above shoulder height then reaches involving that particular weight were avoided for reasons of participant safety.

Reaches and lifts were completed in 15 different directions (3 different angles of asymmetry from the orientation of the WhMD at 5 different heights). The angles of asymmetry included 0, 45 and 90-degrees from the sagittal plane that passes through the acromion process on the individual’s dominant side (i.e. forward, asymmetric and side reaches, respectively). The five heights were normalized to the individual's vertical reach capabilities so that reaches were performed at, above and below shoulder height.

Three-dimensional reach data were collected with the electromechanical probe (FaroArm, Faro Technologies). Use of the electromechanical probe required manually digitizing the 3-D location of the maximum reach point after the cylinder was positioned (Figure 2‒3). The point data were used to measure reach distances from reference points (e.g. maximum forward reach from the front of the WhMD, or maximum side reach from the lateral-most point of the WhMD), and construct reach envelopes that illustrate the reaching capabilities of the sample in 2-D and 3-D space.

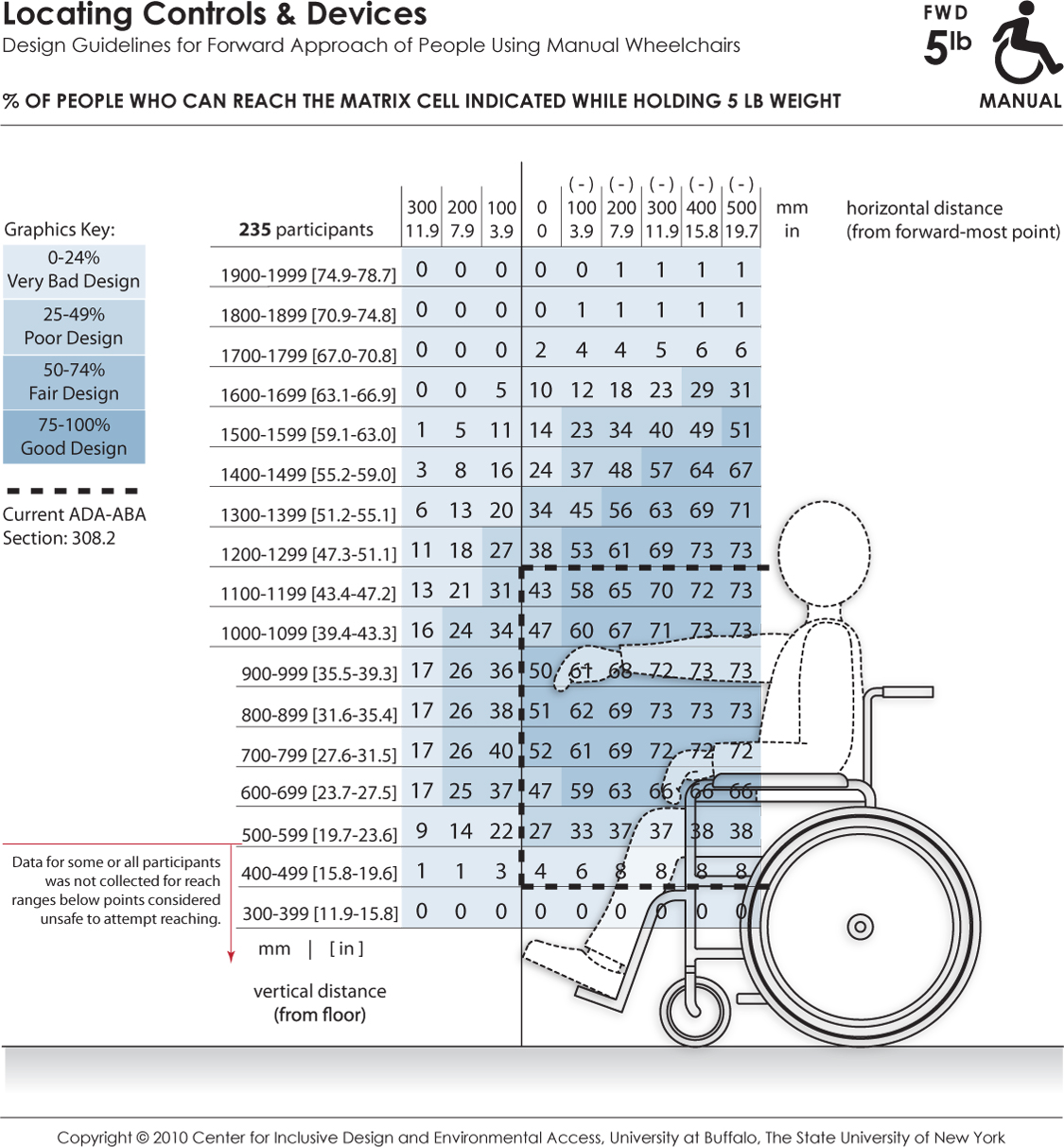

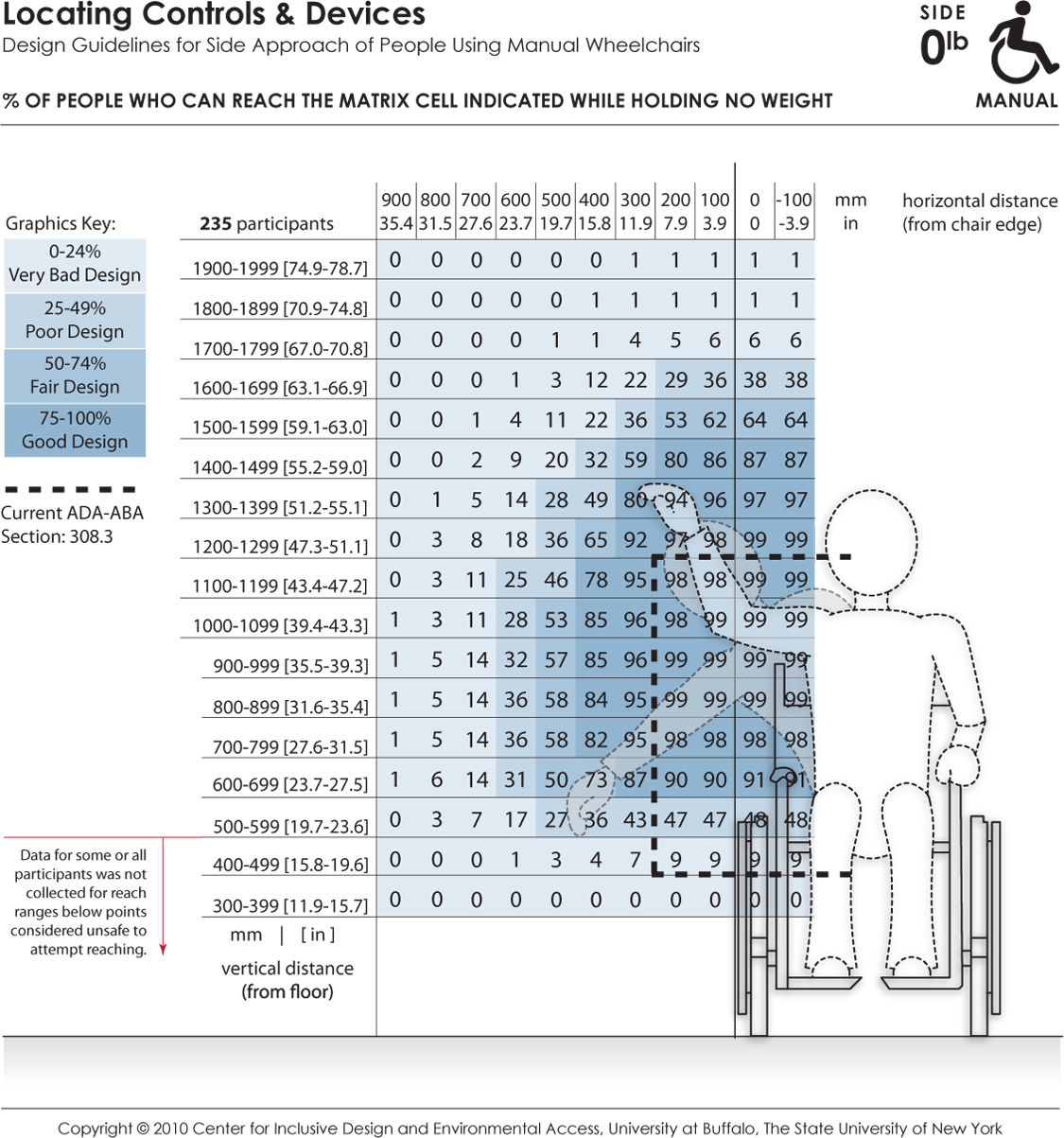

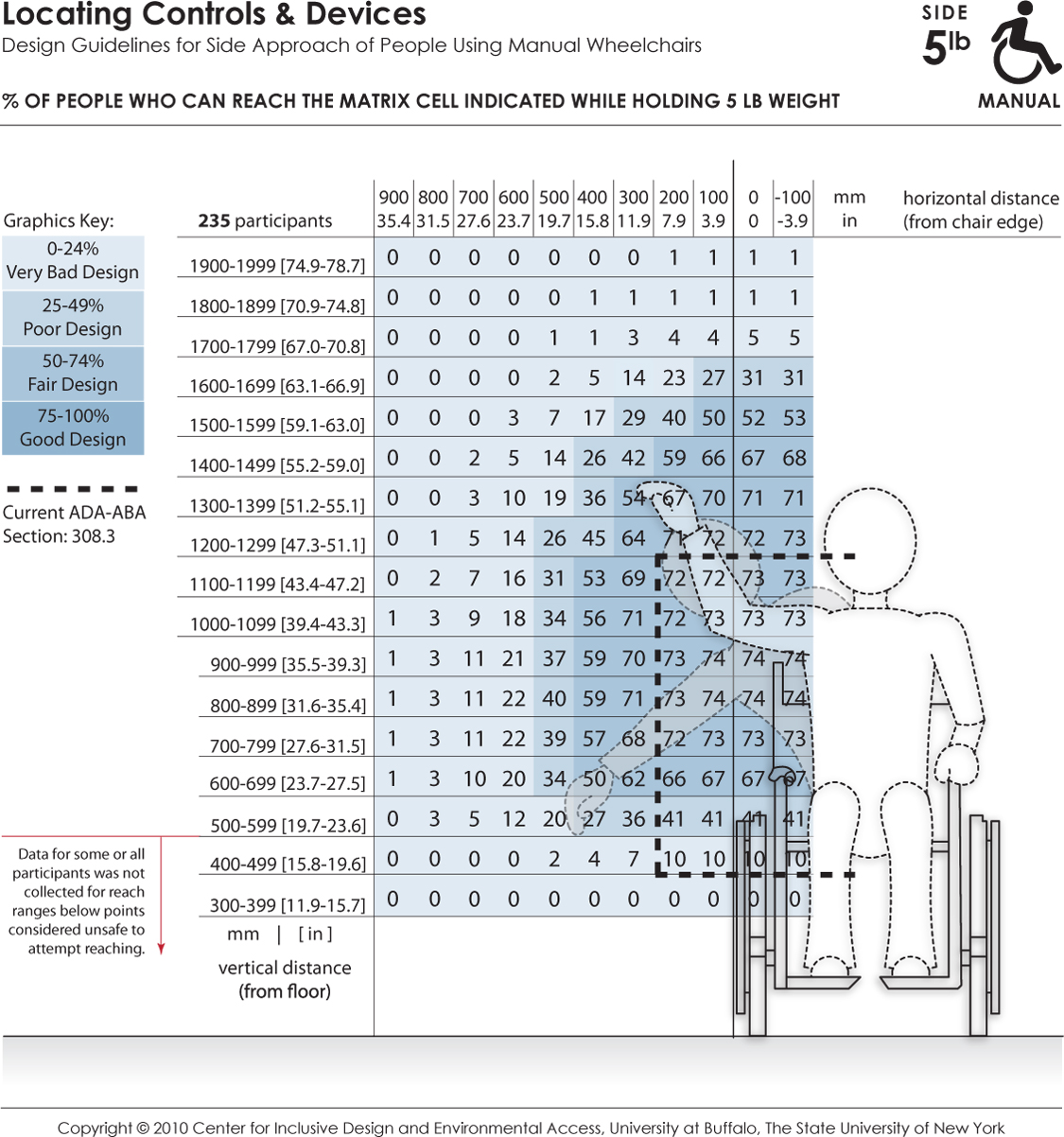

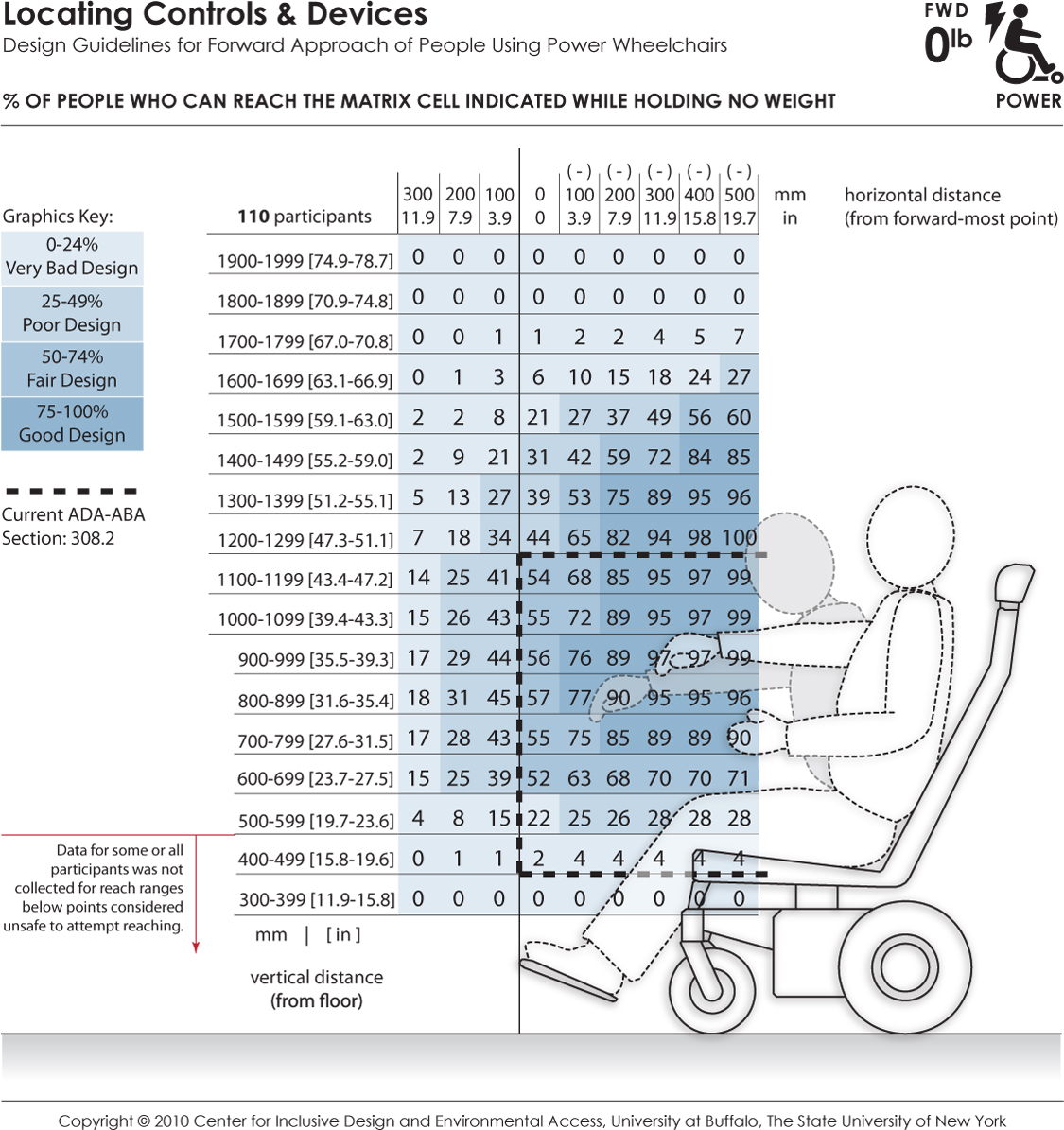

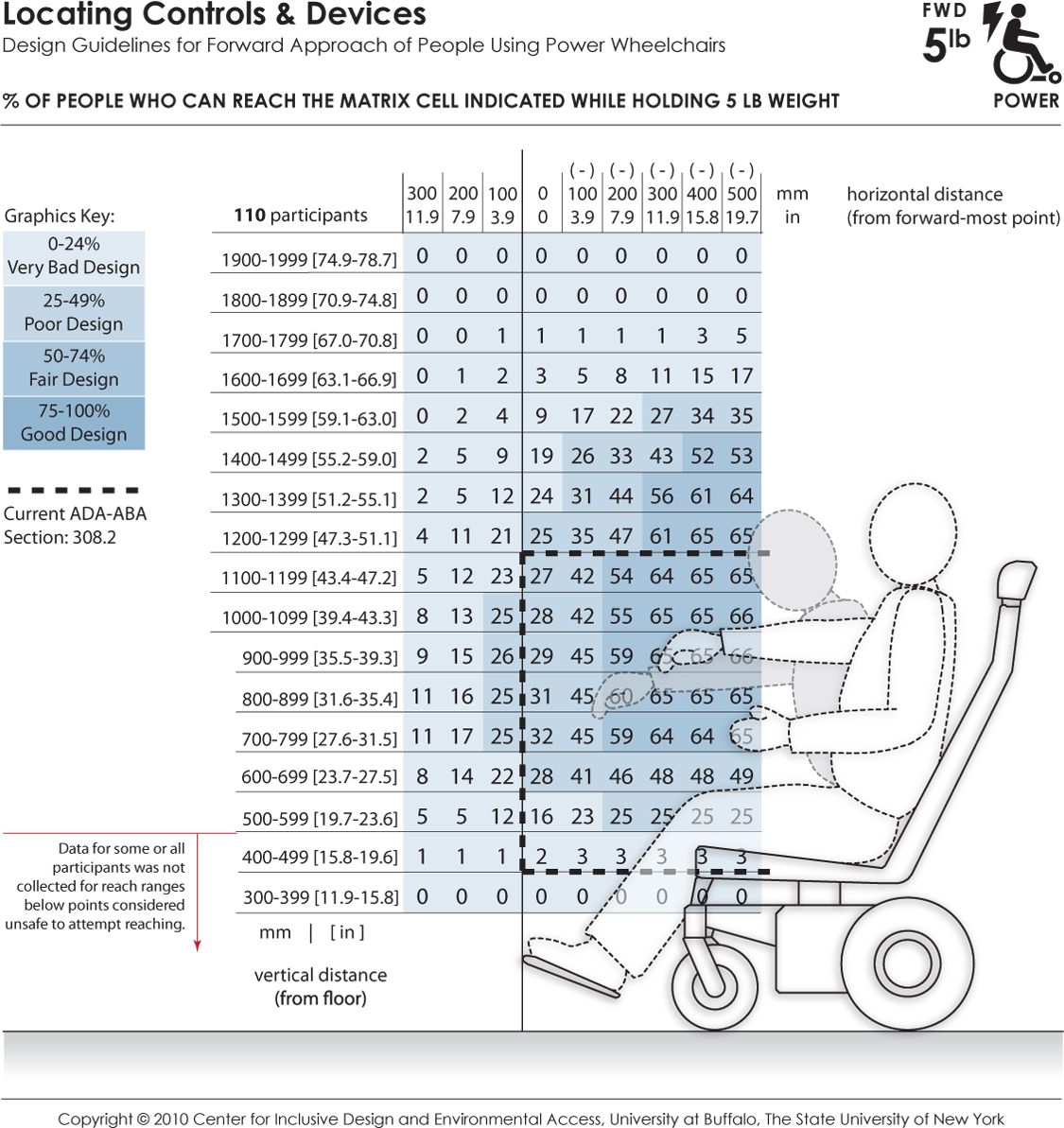

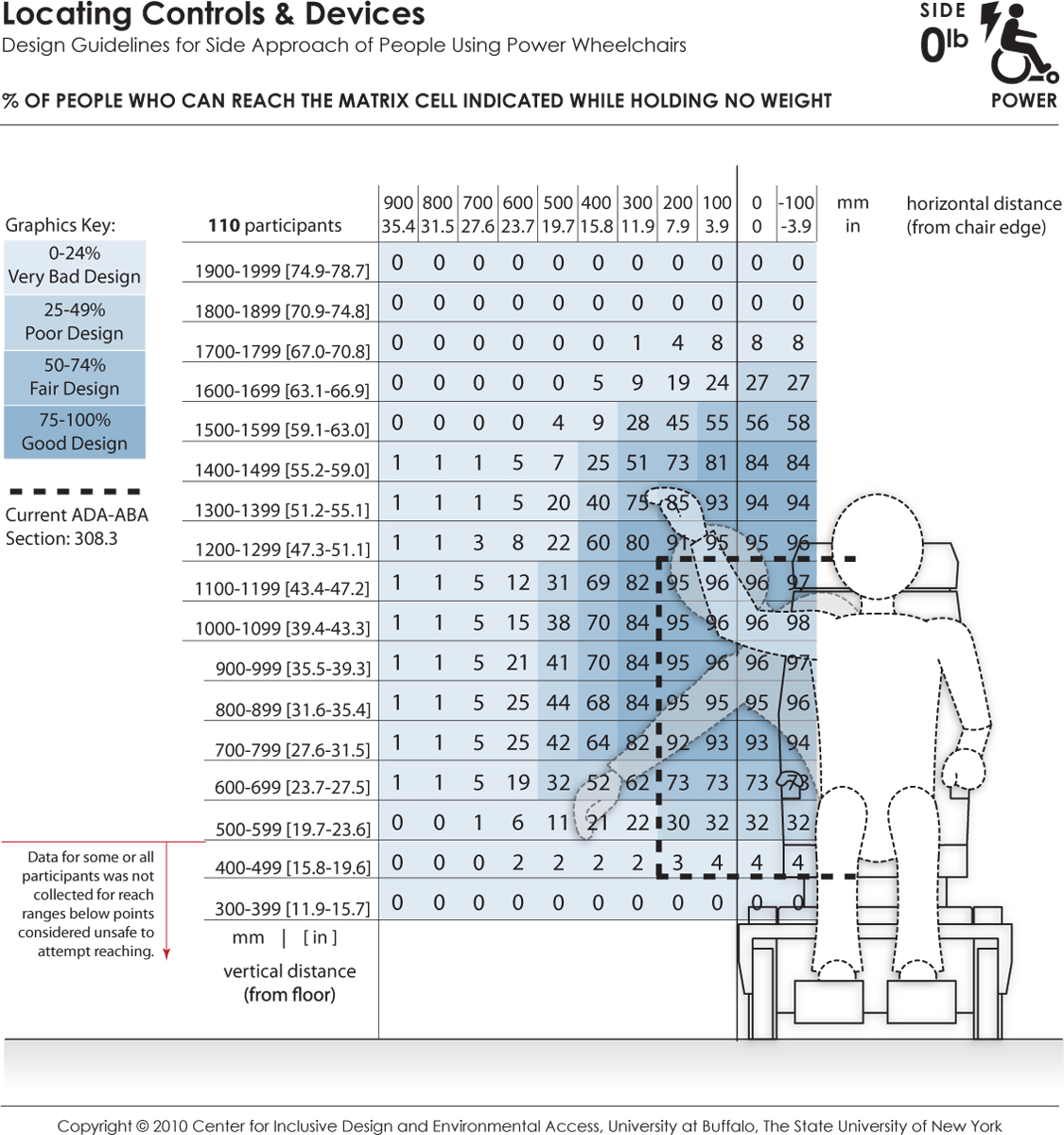

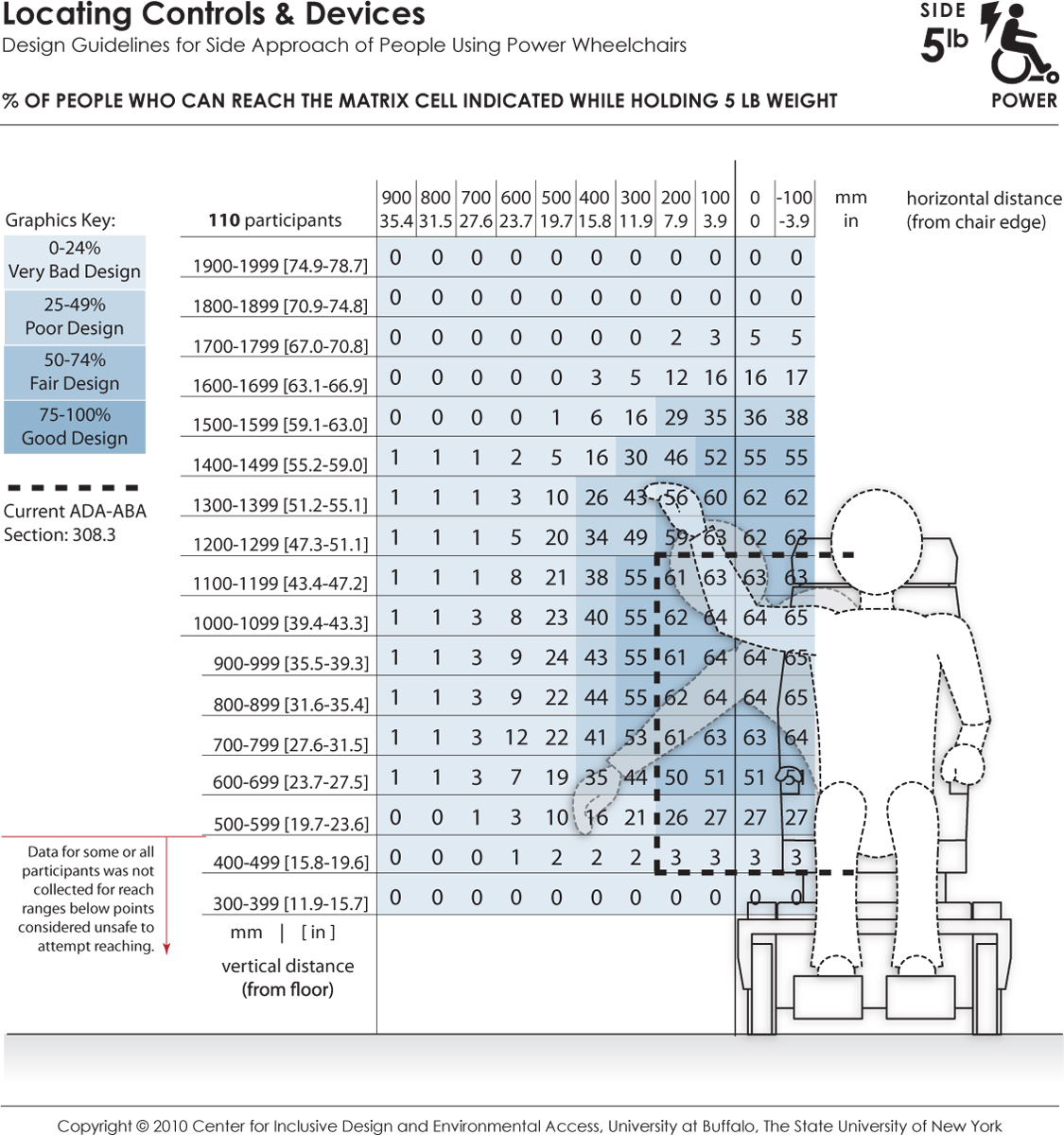

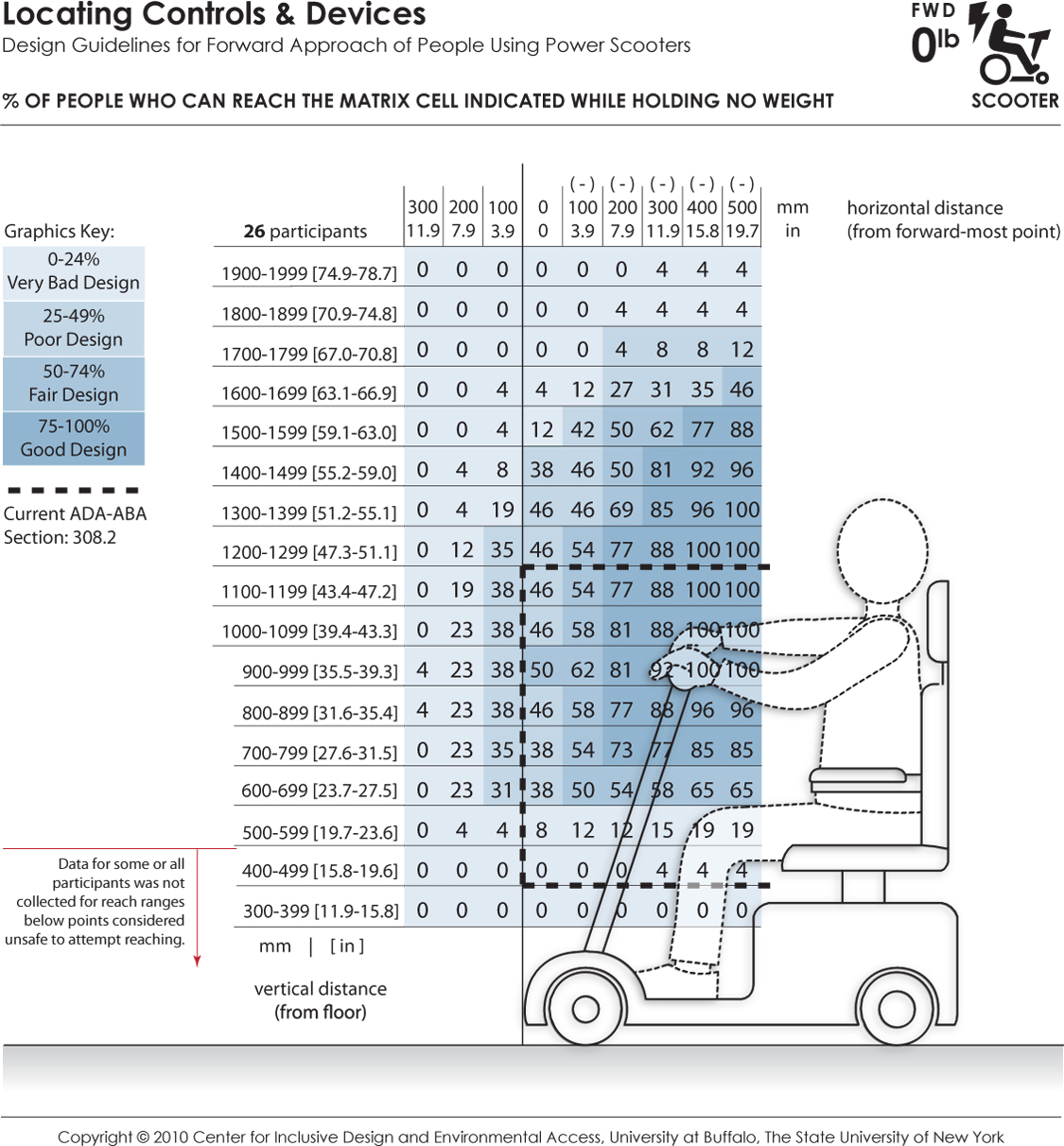

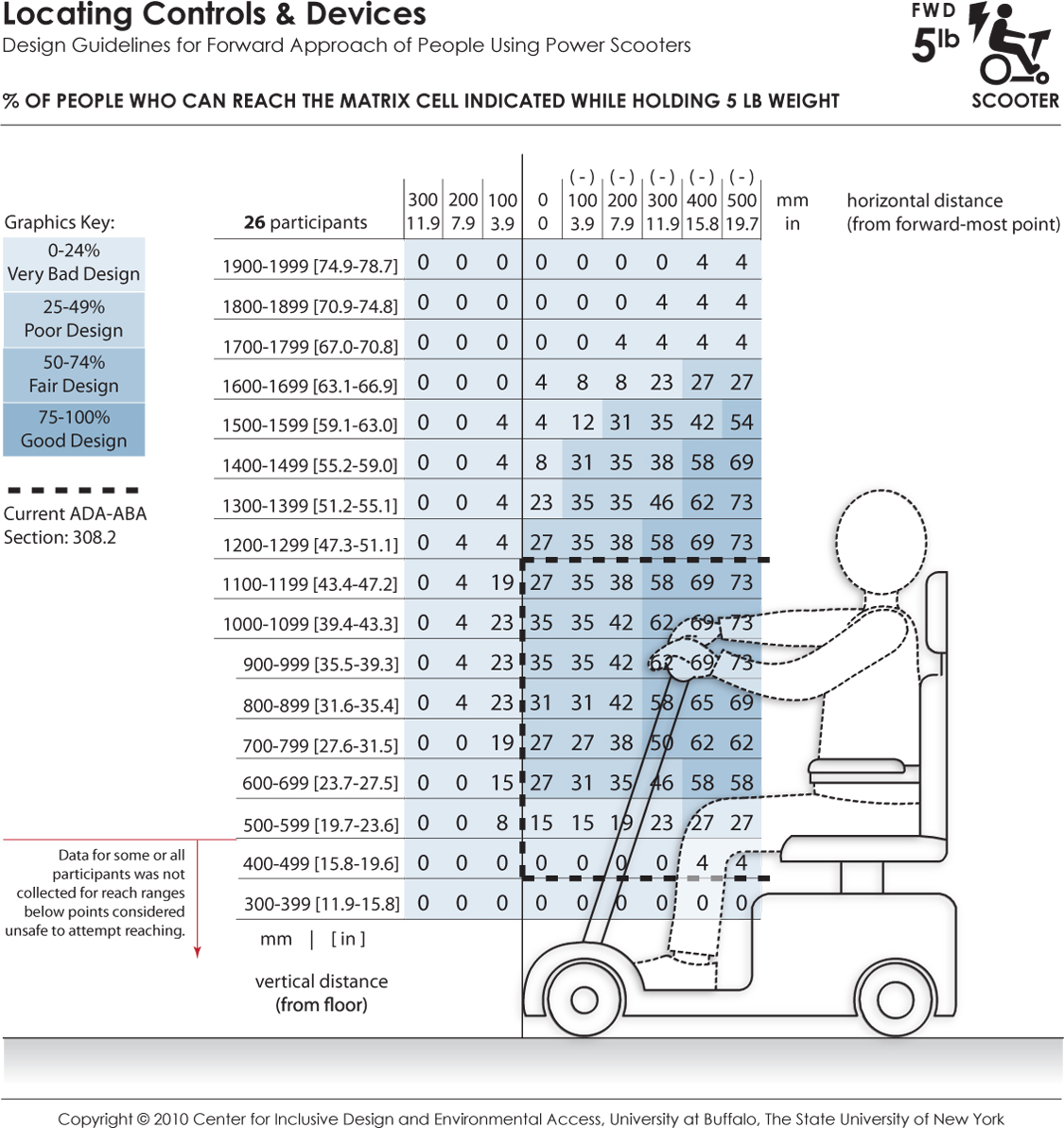

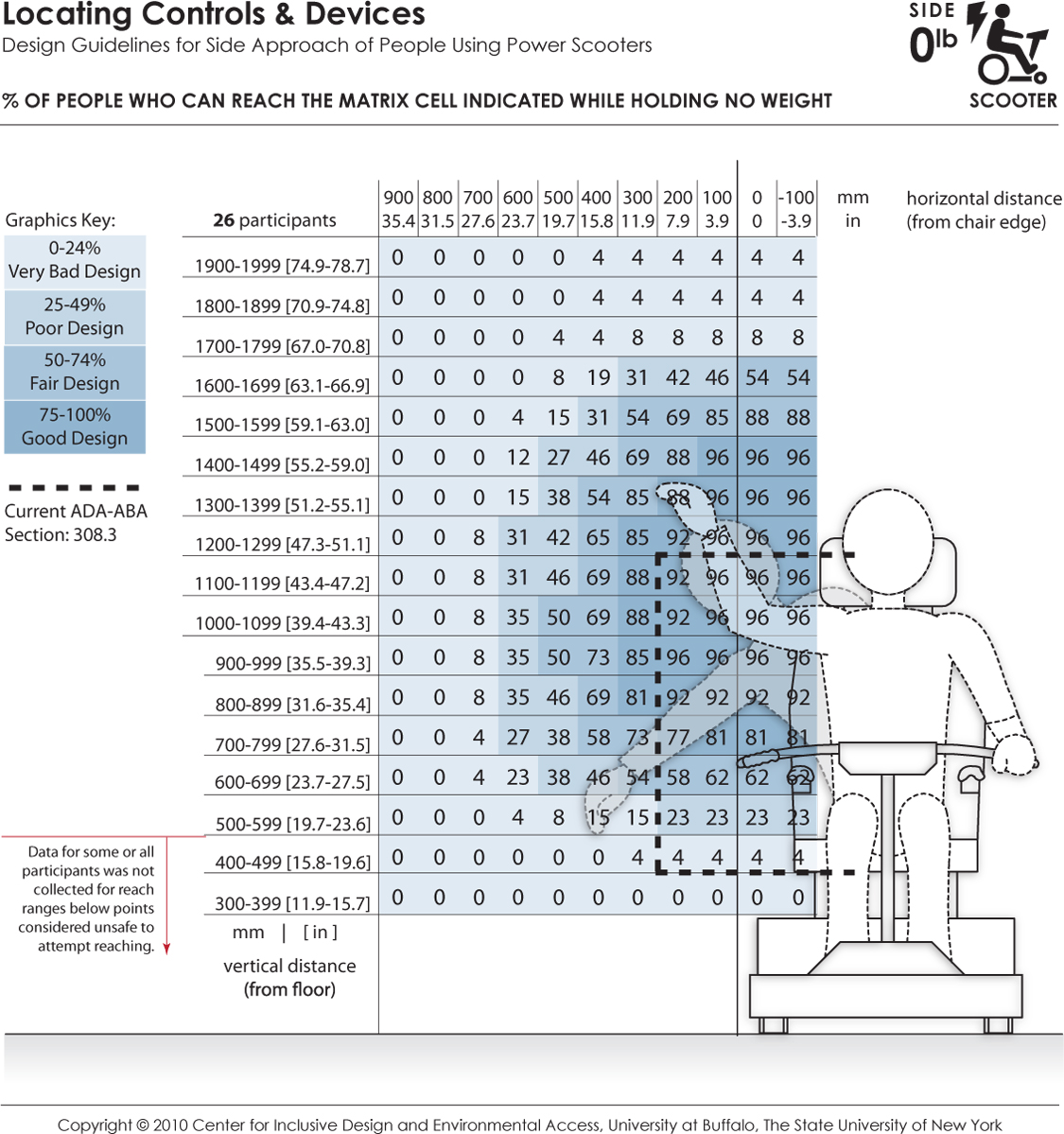

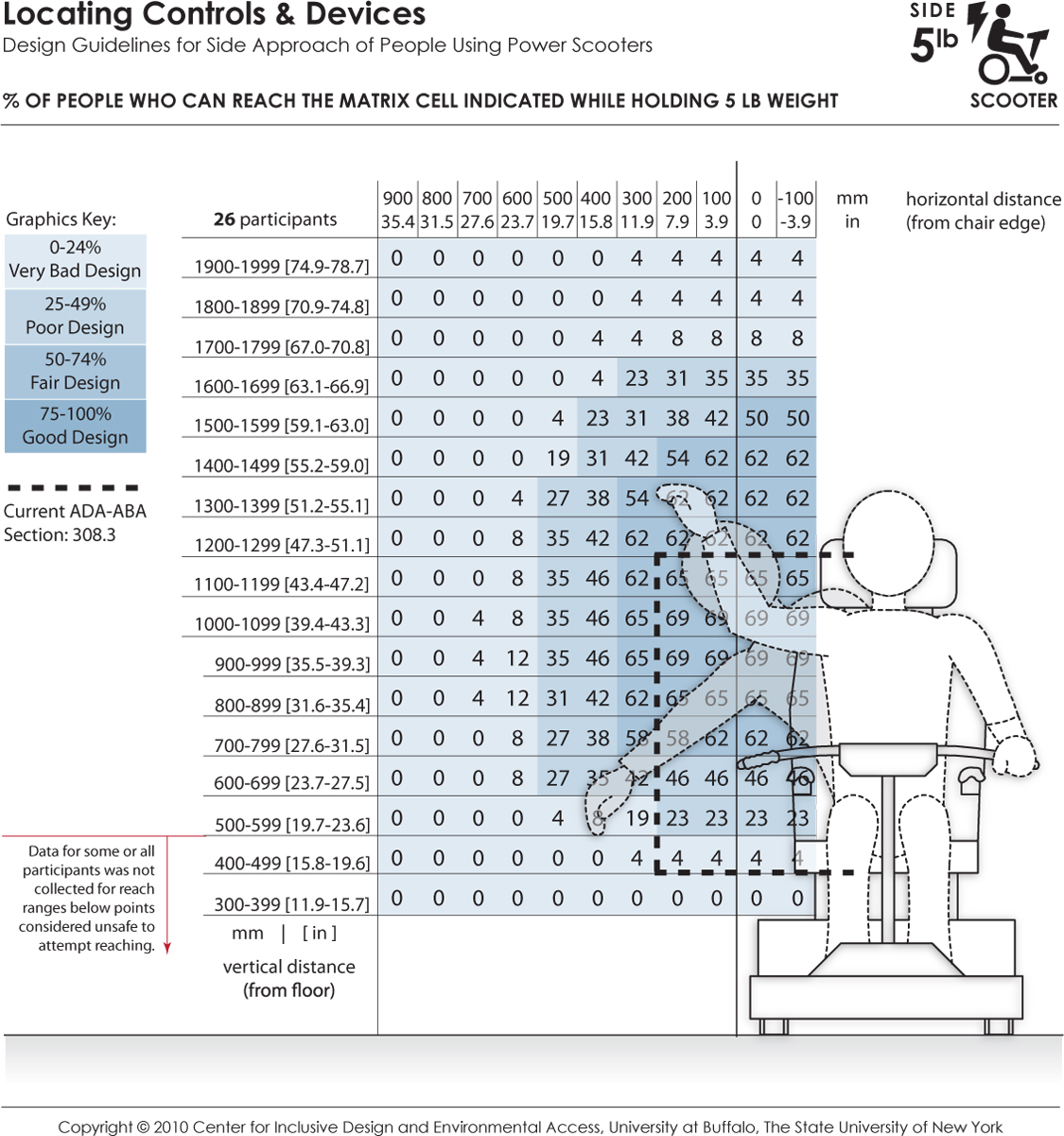

A computation procedure was developed for performing analyses on reaches that involved combining 3-D reach information from the measured WhMD users in relation to a common reference plane. For instance, a vertical plane at the anterior-most point was used a reference to analyze forward reaches. This is similar to a wheelchair occupant facing a wall such that the forward-most aspect of their foot and/or wheelchair was touching the wall. Likewise, a vertical plane at the lateral-most point was used as a reference for analyzing lateral reaches, similar to a situation where a wheelchair occupant were right alongside a wall.

The percentage of WhMD users able to reach to or beyond a particular reference plane (either forward or lateral) was then computed. The data were analyzed in 100 mm (4 in.) increments from the floor. The reference planes could also be moved away or towards the occupant to simulate different obstruction depths to estimate the relative increase or decrease in reach capability. It should be emphasized that our data depict, in percentages, the reaching capabilities of only those individuals who could grasp and lift a particular cylinder above shoulder height.

Figure 2‒3. Participants moved cylinders in 3 different directions at 5 different heights. Shown are forward reaches for two different heights. The electromechanical probe is used to record the 3-D location of the maximum reach distances from body and wheelchair reference points.

2.2.4 Maneuverability

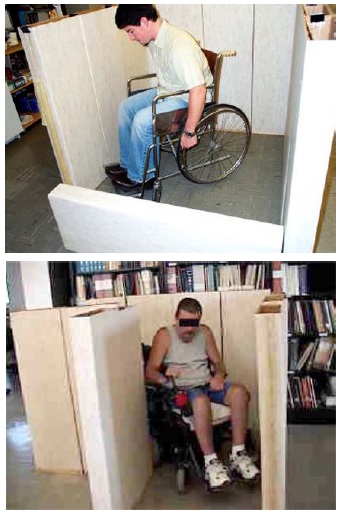

WhMD users were video recorded while completing the following tasks:

• 90-degree turn,

• 180-degree turn with no restrictions on length of the maneuver,

• 180-degree with a center barrier,

• 360-degree rotation within a space with four walls.

The tasks were performed in restricted space conditions with the maneuvering performed within the confines of temporary barriers that are made of cardboard. Widths of the restricted space were set at a minimum of 750 mm (30 in.) for the 90-degree turn, 750 mm (30 in.) passage width for the U-turn with a barrier, and 1300 mm (51 in.) for the 180-degree and 360-degree turning activities.

WhMD users were asked to complete the tasks without touching the walls. The separation between walls was increased at increments of 50 mm (2 in.) if passage through the mock environment was not cleared without touching the walls (Figure 2‒4).

Figure 2‒4. Two examples of WhMD users completing restricted space experimental conditions.

2.2.5 Grip Strength

Four types of grip strength measurements for the dominant hand were assessed. These included a power grip with the elbow in full extension (i.e. shoulders flexed 90-degrees and upper extremity fully extended), power grip with the elbow flexed 90-degrees, lateral pinch (i.e. with the pinch gauge between the thumb pulp and the radial aspect of the forefinger), and thumb-forefinger pinch (i.e. with the pinch gauge between the tips of the thumb and forefinger). These measurements are important to the design of and/or standards development for some types of hand tools, hardware and electrical controls (e.g. scissors, some types of door latches, knob controls). Grip strength was recorded with manual hand and pinch dynamometers (Jamar, Inc). WhMD users were required to perform three maximal efforts in each of the four types of grips with their dominant hand, with the mean value considered as the maximal force value for analysis. Force measurements were not obtained for those WhMD users that were unable to perform a grip or exert a grip force, or declined from grip measurements (e.g. due to pain or discomfort in the hand). If the person could not complete all three force repetitions, force data for that particular grip was not included in the analysis.

Prior analysis of a subset of this data (D’Souza et al., in review) showed maximal power grip forces to be greater on average by approximately 1% to 5% with the arm in full extension as compared to with the elbow flexed 90-degrees on average across gender and mobility device type. In light of this marginal difference, only the power grip data measured with the elbow flexed 90-degrees along with data on pinch grips are included in this report. Additional analyses of this data to study potential differences in grip strength capabilities by age and medical condition that may clinical relevance have also been reported (e.g. Joseph et al., 2010).

2.2.6 Door Use

Our study of door use had three main objectives all intended to provide groundwork for future studies aimed at design guidelines and standards that would make doors more accessible to WhMD users:

1. Identify door use tasks that present WhMD users with the most difficulty,

2. Evaluate how different aspects of door design effect door use difficulty, and

3. Identify which WhMD user groups experience the greatest difficulties with doors.

The door use tasks required the use of three different doors in the building housing the IDeA Center. Trials in both directions were performed (i.e. from push and pull sides) using a forward approach. Each door presented different types of challenges to WhMD users. The door characteristics are summarized in Table 2‒3.

For each trial, use of the door was divided into six task components: Opening Maneuver, Operating Latch, Opening, Through Passage, Closing Maneuver and Closing (See Figure 2‒5). For each phase, the level of difficulty experienced during each task was assessed using a 4 point scale and definitions previously developed and tested by Danford and Steinfeld (1999):

1. Minimal effort: The task was performed successfully on the first attempt, without an expression of frustration, smoothly without interruption, and in no more time than it would take for a member of the general population.

2. Moderate effort: The task was performed successfully on the first attempt, with no more than a brief expression of frustration and infrequent pauses or slight difficulties that increase the task time slightly as compared to a member of the general population.

3. Maximal effort: The task was performed successfully after multiple attempts, often with some expression of frustration and frequent pauses or difficulties that dramatically increases task time as compared to a member of the general population.

4. Impossible: The task was not performed successfully or there was a refusal to complete the task.

5. Blocked View: The effort could not be assessed due to visual obstruction between observer and WhMD user (e.g., door in the way for closing maneuvers, the WhMD user’s body orientation with the observer prevents an assessment).

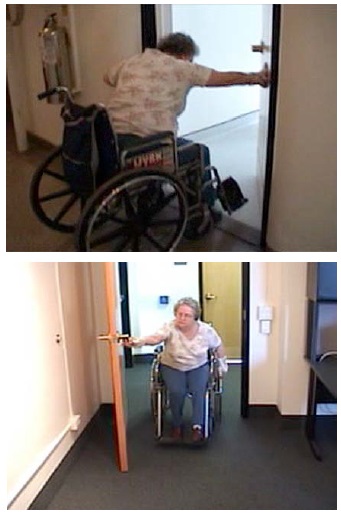

Figure 2‒5. Two examples showing physical requirements of door use for two of the doors used by WhMD users.

2.3 Analysis

2.3.1 Comparison of Demographic Characteristics of Our Sample and U.S. Population of WhMD Users

The size and functional abilities of WhMD users was hypothesized to differ significantly across gender, device type and age of the individual. A comparative analysis between our sample and the population of U.S. WhMD users provided information about the generalizability of our pooled results with the U.S. population of WhMD users. Demographic information about the U.S. population of WhMD users was obtained through summary reports of the 1994‒95 National Health Interview Survey on Disability (Flagg, 2009; Kaye et al., 2000).

The relative percentages of WhMD users stratified by gender, device type and age categories were compared between our sample and the U.S. population of WhMD users. Cases in which our sample was not considered representative on these variables suggest a “stratified analysis” (i.e. presentation of results for sub-samples, rather than the pooled data set) or other statistical modeling methods (e.g. Paquet et al., in preparation) would provide opportunities for a more valid application of our results to U.S. standards. Population-based data about percentage of WhMDs users with different types of disability were not available for the analyses.

2.3.2 Comparison of Demographic Characteristics of Subsamples by Data Collection Location

Because each of the data collection sites had access to different sub-populations of WhMD users and slightly different methods of participant recruitment, we believed it would be important to understand the differences in the demographic characteristics of the sub-samples of each site.

Therefore the relative percentages of WhMD users stratified by gender, device type and age categories were compared across the study’s three data collection sites.

2.3.3 Comparison of Dimensions with Standards and other Anthropometric Studies

The results of our study were compared to the Americans with Disabilities Act Accessibility Guidelines (ADAAG) and the Americans with Disabilities Act – Architectural Barriers Act Accessibility (ADA-ABA) Guidelines for Buildings and Facilities, standards of several countries and findings from several other large non-U.S. anthropometric studies of WhMD users. To identify the dimensions to compare, we first identified the relevant item in the U.S. standards to identify the common underlying anthropometric variables. Our analysis then focused only on those variables. The list below identifies the items in the standards and the anthropometric variables which were used for comparison:

• Unoccupied Device Width: Compared to the horizontal distance between the most extreme lateral points of the WhMD.

• Unoccupied Device Length: Compared to the horizontal distance between the most extreme posterior and anterior points of the WhMD.

• Clear Floor Space Width: Compared to Occupied Width.

• Clear Floor Space Length: Compared to Occupied Length.

• Seat Height, maximum: Compared to the vertical distance measured from the floor to the height of the seat support surface when occupied.

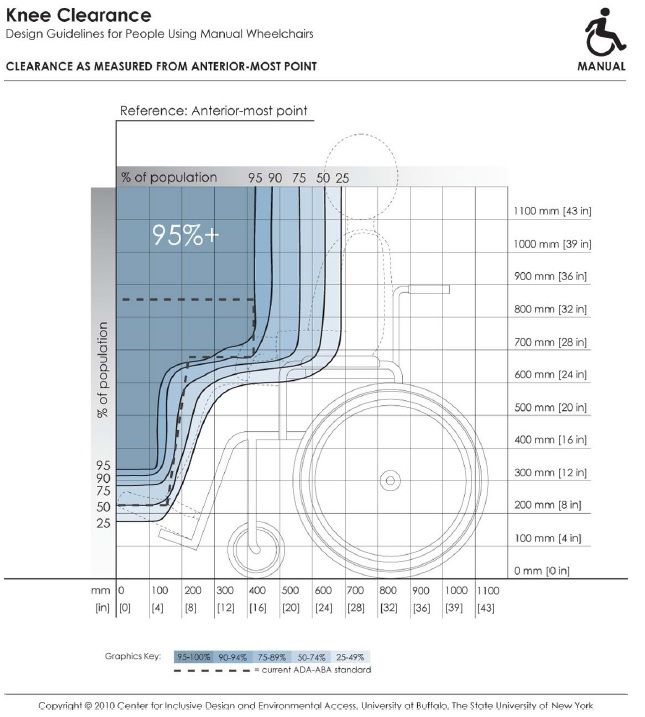

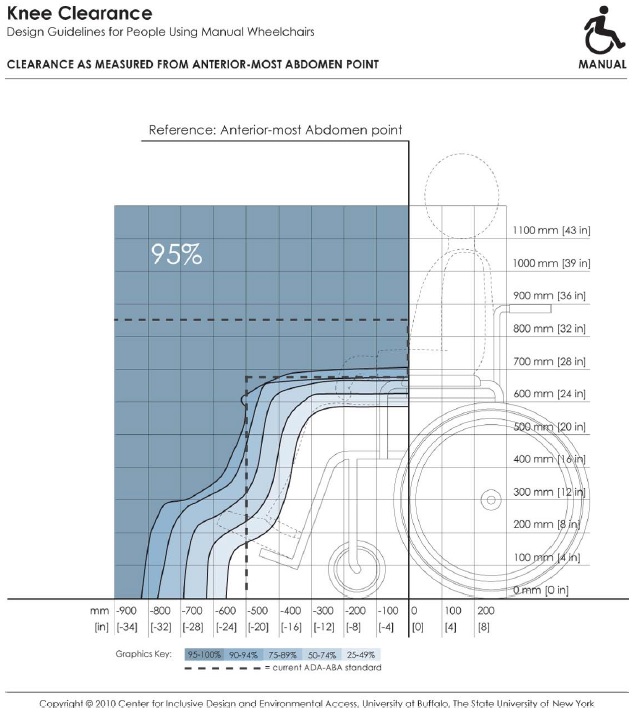

• Knee Clearance Height, minimum: Compared to the vertical distance measured from the floor to the superior aspect of the right knee.

• Toe Clearance Height, minimum: Compared to the vertical distance measured from the floor to the highest point on the right foot (i.e. higher of either the dorsal or distal foot point). This measure was only considered for manual and power wheelchair users.

• Knee Clearance Depth, minimum: Compared to the horizontal distance measured from the distal aspect of the right knee to the anterior-most point on the occupant and/or wheelchair. This measure was only considered for manual and power wheelchair users.

• Toe Clearance Depth, maximum: Compared to the horizontal distance measured from the dorsal aspect of the foot (i.e. crease of the foot and lower leg) to the anterior-most point on the occupant and/or wheelchair. This measure was only considered for manual and power wheelchair users.

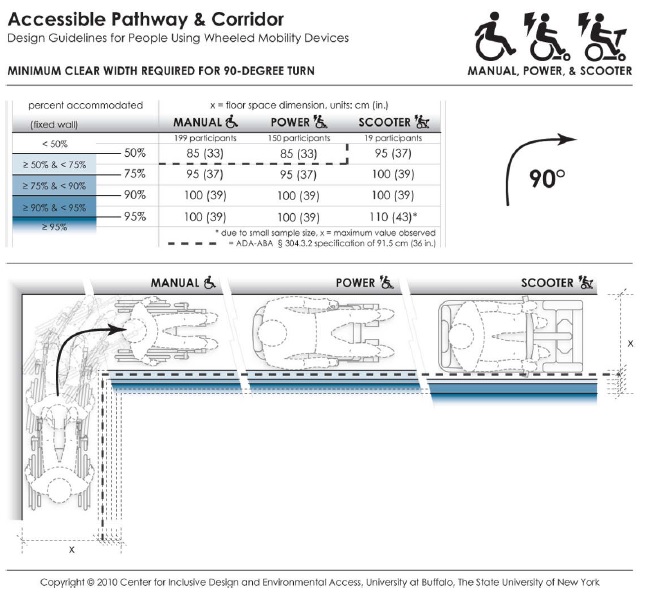

• Wheelchair Turning Space to make a 90-Degree Turn: Compared to the maneuvering clearances required for performing a 90-degree (L-shaped) turn.

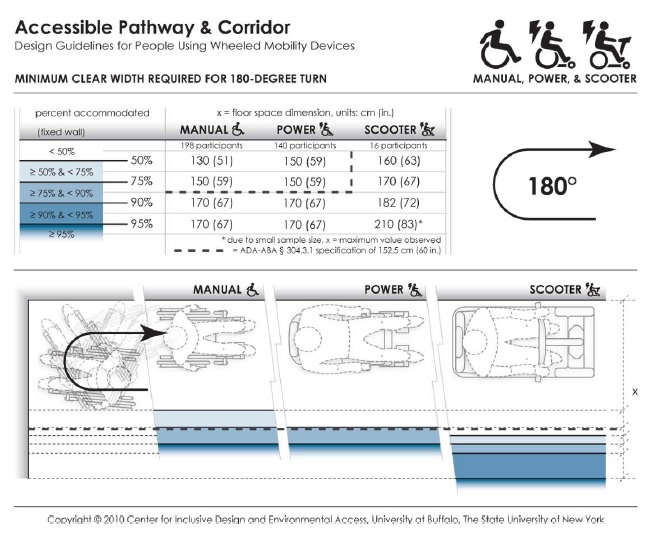

• Circular and T-shaped Wheelchair Turning Space: Compared to the maneuvering clearances required to make a 180-degree turn in a space confined on three sides.

• Wheelchair Turning Space to make a 180-Degree Turn around an Obstacle: Compared to the maneuvering clearances required to make a 180-degree turn around a center barrier.

• Circular and T-shaped Wheelchair Turning Space: Compared to the maneuvering clearances required to make a 360-degree turn in a space confined on all four sides.

• Forward Reach Height Lower and Upper Limits: Compared to the measured heights that WhMD user could reach beyond the anterior (forward) most point of the WhMD user or device.

• Side Reach Height Lower and Upper Limits: Compared to the measured heights that WhMD user could reach beyond the most lateral point of the WhMD user or device.

• Side Reach Height Lower and Upper Limits over an obstruction of 610 mm: Compared to the measured heights that WhMD user could reach 610 mm beyond the most lateral point of the WhMD user or device.

• Maximum Forces for Hand-operated Controls: Compared to the maximum hand grip strength in a power grip, and lateral and thumb-forefinger pinch grips.

In order to accomplish the comparative analysis with the standards and other studies, we reviewed ICC/ANSI A117.1 (2003) Accessible and Usable Buildings and Facilities, which serves as the model for the technical requirements in the federal guidelines in the U.S., the Americans with Disabilities Act Accessibility Guidelines (ADAAG) and its eventual replacement, the Americans with Disabilities Act – Architectural Barriers Act Guidelines (ADA-ABA). For the United Kingdom (U.K.), we reviewed BS 8300:2001 Design of Buildings and Their Approaches to Meet the Needs of Disabled People – Code of Practice. For Canada (CA), we reviewed B651‒04 Accessible Design for the Built Environment. For Australia (AUS), we reviewed AS 1428.2 – 1992 Design for Access and Mobility Part 2: Enhanced and Additional Requirements – Buildings and Facilities. Table 2.4 summarizes Accessibility Standards that were used for the comparisons.

Table 2.4 Comparison of Accessibility Standards across Four Countries.

* This standard also includes an appendix with information on device size and maneuvering spaces for power chairs and scooters derived from the UDI research.

Since the findings of anthropometric research are often voluminous, journal articles and book chapters do not usually include a full documentation. Thus, we obtained the original research reports from Ringaert et al. (2001) from Canada, Stait et al. (2000) from the United Kingdom, Bails (1983) and Seeger et al. (1994) from Australia. The research underlying BS8300:2001 in the U.K. was summarized in an Annex to the standard itself but we were unable to obtain a more comprehensive report that described the details of the methodology. Each of the studies is briefly described below. See Steinfeld et al. (2010c) for a more complete summary of each.

In his study, Bails (1983) recruited participants from attendees at disability support centers and institutions. Eligible participants were between 18 and 60 years of age and used a manual or powered wheelchair. Scooter users were not included in the study. The research focused primarily on testing of full-size simulations of elements found in the built environment, such as doorways, environmental controls, furniture and fixtures that were configured to meet the Australian standards at the time.

Seeger et al. (1994) studied only device size. About 73% of the 240 individuals in the sample lived in nursing homes and other institutions. Forty-five percent were over 65 years old. Eleven percent used power chairs and 2% used scooters. Both unoccupied and occupied dimensions of device width and length were measured as well as a set of other basic dimensions. Measurements were taken manually using conventional measuring tools including a tape measure, steel square and spirit level.

The Department of Environment Transport and the Regions (DETR) (Stait et al., 2000) and the Department for Transport (DfT) (Hitchcock et al., 2006) studies were the two most recent in a series of three large-scale wheelchair anthropometry surveys conducted in the U.K. The studies were limited to the measurement of device size and weight. The DETR survey conducted in 1999, recruited participants solely at an exposition of equipment for people who use wheeled mobility devices for traveling around the community. The subsequent DfT survey was widened to include 12 schools and retail centers in the U.K., in addition to the 2005 Mobility Roadshow. Of the 745 participants in the DETR study whose data was acceptable, 59% used self-propelled manual chairs, 9% used attendant powered chairs, 25% used power chairs and 9% used scooters. Nine percent of the sample were judged to be 16 years of age or younger. The DfT study sample comprised of 1098 adults and 247 children. Among adults, 41% used self-propelled manual chairs, 10% used attendant-propelled wheelchairs, 27% used power chairs, and 22% used scooters. The DETR study used two photographs of each participant, while the DfT study employed seven photographs taken with a camera from pre-determined angles after participants wheeled into position on a scale. A checkerboard pattern on the floor and wall provided references to take measurements off the photographs. Although a wide variety of accessories were observed on the devices, they were not measured as part of the width calculation.

The research used as a basis for revisions to the U.K. BS8300:2001 standards covered clear floor area space requirements, knee clearances and maneuvering clearances. A total of 164 individuals were included in the sample but only 90 participated in the research on space allowances. Due to the lack of a full research report, it is not clear how the measurements were collected and, in many cases, the landmarks used to define them. From the information available, it appears that some scooters and attendant propelled chairs were included in the sample but it is not clear whether these individuals were included in the device or body measurements.

The Universal Design Institute (UDI) study (Ringaert et al., 2001) included a sample of individuals recruited from disability and senior organizations in Winnipeg by written invitation. Of the 50 participants, 35 (70%) used power chairs and 15 (30%) used scooters. The cause of disability for individuals in the sample included a wide range of conditions. Device size and maneuvering spaces were measured. All dimensions were taken to the extremes of the equipment including any object attached to the device like a ventilator. However, the actual landmarks on the devices were not well documented. Measurements were made with rulers and tape measures but no information is given on the accuracy and reliability of these techniques. Maneuvering trials were recorded using overhead video cameras while participants completed standardized movements in simulated environments built with plywood floors and wood framed dividers. Measurements were later taken off the videotapes although the method used to extract the measurements and the reliability of the technique was not described. An observer rating was used to determine successful trials.

The common variables were defined graphically in illustrations and with abbreviations, e.g. Knee Clearance Height (KCH), Knee Clearance Depth – Upper (KCD), and Extended Depth (ED). In many cases, variables underlying the U.S. standards are not included in other standards. Thus, in our comparisons, we omitted values for those variables. We did not, however, report variables from other standards that are not included in the U.S. standards.

The standards did not always use the same variables (or parameters), terminology or measurement conventions. For example, the U.S. standards include both Imperial and “soft” conversions to Metric units, but all the other standards are in Metric units only; there are at least three different terms used for a “wheelchair turning space”, and the U.K. standards report reach ranges for both a “maximum” and “minimum” reach while the U.S. standards have only one range delimited by a minimum and a maximum value.

These differences present several problems to researchers. For example, the definition of a “wheelchair turning space” determines the protocol used to study the clearance needed. Different results are obtained if that space is bounded or unbounded or whether the protocol calls for a smooth continuous turn or includes a series of smaller movements or allows either. Since the standards do not define variables clearly, researchers have made their own interpretations and developed different protocols to study the same variables. Thus, to make comparisons, we standardized all the values from standards and research as much as possible based on a common definition of variables and measurement conventions. We reported the U.S. values in both Imperial and Metric units but did not convert the other countries’ values to Imperial nor did we do “hard” conversions of the Imperial values found in the U.S. standards.

We then reviewed the research completed in each study. In many cases, this required some interpretation because the research studies did not always use the same terms or definitions as the standards in the respective country. Different approaches were also used to report findings. Some results were reported in percentiles. Other results were reported as minimum or maximum values. Still others were reported as the “percentage of subjects accommodated” – those who could perform a task at a certain criterion level.

We devised a graphic method to compare the results of the research studies to each other including our own and to the standards. Most of the studies reported at least a minimum or maximum value and a mean value for each variable studied. These three points were displayed on a graph and coded by study. Where available, percentile data were added to the graph in between the minimum and maximum values and the mean to provide more detail. All the values for each study that represented a distribution were connected by line segments.

For clarity, we pooled data for all mobility devices. However, this can confound comparisons across studies due to differences in the proportion of manual wheelchairs, power chairs, and scooters. Therefore, we also provided tabular data stratified by mobility device type.

2.3.4 Analysis of Door Use Difficulty

The measurement of door use performance was designed as a quasi-experimental study that involved systematically observing and coding WhMD user performance during door use tasks. It therefore required different analysis and comparison approaches.

First, an analysis of the demographic variables for the subset of WhMD users who completed the door use tasks was completed to describe the percentages of men and women, and types of WhMDs used in this sub-group. The mean, median and range of WhMD user age, occupied width, occupied length and maximum power grip were also reported as we thought that these variables might help explain the door use performance among the sub-group.

The level of difficulty experienced for each of the phases of door use was then compared across the three different doors and WhMD types for each of the tasks. Specifically, the percentage of each of the rating scores (minimum effort, moderate effort, maximum effort and impossible) was calculated for each of the three doors and six door use tasks. Those doors and door use tasks having a relatively large percentage of scores exceeding minimum effort were identified as potentially problematic, and a follow-up analysis of these conditions was performed to determine which WhMD user groups had the greatest difficulty with these tasks.

3.0 Study Findings

3.1 Comparison of Our Sample to U.S. Population of WhMD Users

Our sample of WhMD users was younger in age, had a much higher percentage of powered wheelchair users and a somewhat larger sample of male WhMD users than the estimated U.S. population of WhMD users (Table 3‒1). As stated in the previous section, we deliberately over-sampled powered device users in order to be able to accurately describe the anthropometric characteristics of this group. The higher frequency of male WhMD users recruited for this study is not very surprising as two of our data collection sites (Buffalo and Pittsburgh) recruited some of their study participants through VA medical centers that had extremely high percentages of male patients. As a result, our overall sample, when compared to the overall population of WhMD users is likely to have lower upper extremity and torso function, and be somewhat larger (i.e., taller, longer arms, wider, etc.). As stated in the previous chapter, these sample differences can be accounted for by stratifying the data by WhMD and/or by gender, or through the use of statistical modeling methods (Paquet et al., in preparation).

In terms of the medical conditions, Kaye et al. (2000) reported orthopedic impairments of the lower extremity (17% when combined with arthritis and other polyarthritis to conform with the classification used in the current study), cerebral vascular diseases (e.g. stroke, 11%), and central nervous system disorders (8%, including multiple sclerosis and cerebral palsy) as being the most frequently reported conditions leading to the use of a WhMD in the U.S. population. The most frequently reported medical conditions in our study were found to be central nervous system disorders (32%, including multiple sclerosis and cerebral palsy), spinal cord injuries (20%), cerebral vascular diseases (16%), followed by orthopedic impairments of the lower extremity (12%). The higher prevalence of spinal cord injuries in our study sample is expected given that two of the study locations recruited substantially through local VA medical centers.

Table 3‒1. Comparison of the percentages of WhMD users by gender, device type and age based on the estimated U.S. population of non-institutionalized WhMD users (Kaye et al., 2000) and our sample of WhMD users (n=495).

3.2 Comparison of Sub-samples across Data Collection Sites

The primary purpose of expanding data collection to different sites was to increase the diversity of the overall sample. The Buffalo site, having recruited participants for close to 10 years had a relatively diverse sample of individuals recruited through the local Independent Living Center, a local VA medical center, and local adult care facilities. The Pittsburgh site recruited primarily through a local VA medical center. The Ithaca site recruited through local adult care facilities.

Not unexpectedly, large differences in WhMD users in terms of gender, age, years with disability and device type used were found (Table 3‒2). Pittsburgh had a much higher percentage of men WhMD users (73%) as compared to Ithaca (57%) and Buffalo (46%). It has been our experience that men are more likely to participate in the study, and the Buffalo site specifically targeted female WhMD users in our last phase of data collection to improve the representativeness of the data set in terms of gender. The median age of WhMD users was highest for the Ithaca site (74 years) followed by Buffalo (57 years) and Pittsburgh (44 years). Ithaca, and Buffalo in the later stages of data collection, recruited primarily from adult care facilities in order ensure that older WhMD users were well represented in the sample.

The disparities in the time WhMD users had their disabilities can also be explained by the differences in sampling approaches across the sites. By concentrating on veterans, the Pittsburgh site recruited WhMD users with disabilities for the largest number of median years (20 years) as compared to Buffalo (15 years) and Ithaca (10 years). This illustrates that the WhMD users recruited by Pittsburgh were more likely to experience their disability at an earlier age than the other two sites, while the WhMD users recruited by Ithaca were likely to have first experienced their disabilities at a much older age.

Table 3‒2: Gender, age and number of years with disability across sites.

There were also large differences in the medical condition reported as being responsible for the need to use a WhMD across data collection sites (Table 3‒3). Pittsburgh by far had the largest percentage of spinal cord injured WhMD users and lowest percentage of orthopedic injuries and deformities. The greater percentage of acute injury related mobility impairments such as spinal cord injuries for the Pittsburgh site is expected given that most of its sample was recruited through a VA medical center. The Buffalo and Pittsburgh sites each had sub-samples with a diverse set of medical conditions.

Table 3‒3: Reported primary medical conditions among WhMD users across sites.

* “Other” includes amputations, traumatic brain injuries, respiratory diseases and diabetes.

The disparities across the three sites in terms of the percentages of WhMD technologies were largest between the Ithaca and the other two sites (Table 3‒4). The Ithaca site measured a much higher percentage of manual wheelchair users than Pittsburgh and Buffalo, which is not surprising given the distribution ages and reported medical conditions for the Ithaca site.

Table 3‒4. Primary mobility device used among WhMD users across sites.

Some of the research participants could not complete all of the functional anthropometric tests (i.e. grip strength, reach and maneuvering). The participation rates in these tests were evaluated for each of the sites. The participation rates for the reach and grip tests are summarized in Table 3‒5. Participation rates for the reach tests were lowest in Ithaca where the WhMD users tended to be much older than those of the other sites. The participation rates for the power grips were lowest in Pittsburgh, where there was the highest percentage of WhMD users with spinal cord injury.

Table 3‒5: Participation rates in the functional anthropometric tests for each site.

3.3 Comparison of Dimensions with Standards and other Anthropometric Studies

3.3.1 Unoccupied Device Width

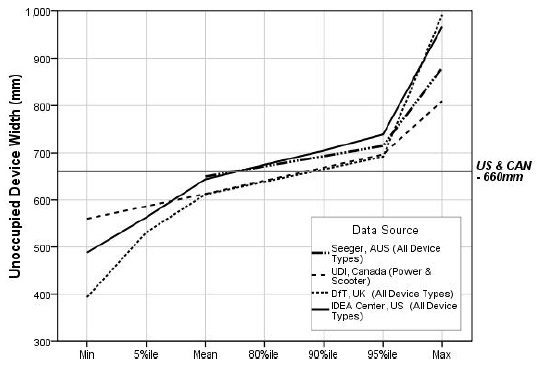

The unoccupied widths of devices were similar for the mean and 80th percentile values across research findings from different countries (Figure 3‒1). Our sample overall had, on average, larger mean and 80th percentile values for unoccupied device width than other countries. This was in part due to the larger percentage of powered wheelchair users and manual bariatric wheelchair users that were included in our study.

The unoccupied widths of devices used for the “reference wheelchair” described in the U.S. and Canadian standards are smaller than many of the WhMD users in our sample. For example, our results for mean unoccupied width are just under the U.S. standard reference wheelchair of 660 mm (26 in.). But, the widest device measured (a manual wheelchair) was over 300 mm (12 in.) wider than the U.S. standard’s reference wheelchair. The U.S. standards, generally accepted by the other countries, were derived from manufacturers’ data in the 1970’s and did not include many of WhMD technologies that are in use today.

* Indicates data plotted in the graph.

Figure 3-1. Unoccupied WhMD width: research findings versus the standards.

3.3.2 Unoccupied Device Length

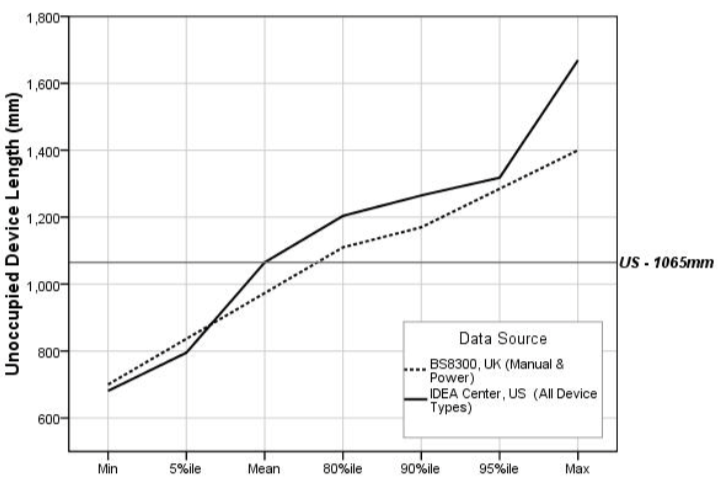

The unoccupied length of devices could be compared only between our study and the U.K. study (Stait et al., 2000). Our findings for mean, 80th percentile and 90th percentile values were somewhat larger than those of the comparison study (Figure 3‒2). This again was likely due to the larger percentage of powered wheelchairs and manual bariatric wheelchairs that were included in our study.

The unoccupied lengths of devices used for the “reference wheelchair” described in the U.S. standard equals the average value obtained from our overall sample. The mean unoccupied length for a powered wheelchair in our sample was 52 mm (2 in.) greater than the unoccupied length of the reference chair given in the standards, and the longest unoccupied length measured in our study was over 600 mm (23.6 in.) greater than the unoccupied length of the “reference wheelchair”!

There are a few reasons for the disparity in our unoccupied length data and the unoccupied length of the “reference wheelchair” currently provided in the standards. First, the available WhMD technologies of today are structurally different than those from which the standards were derived. For example, powered wheelchairs and scooters are generally longer than manual wheelchairs. Second, we measured the unoccupied length of the WhMD while it was in use; thus devices measured with elevated leg supports would be “lengthened.” Third, many of today’s mobility users attach accessories to the back of their device; we included the accessories in our length measurements.

* Indicates data plotted in the graph.

Figure 3-2. Unoccupied WhMD length: research findings versus the U.S. standards.

3.3.3 Clear Floor Width

The findings on clear floor width are based on the findings on occupied width from anthropometric studies shown in Figure 3‒3. Neither the DfT or DETR studies collected data on occupied width but did measure the unoccupied device width. The authors argued that individuals can bring their arms and legs inboard when entering transportation vehicles and passing through doorways. We found, however, that many individuals do not have the physical ability to position their upper and lower extremities “inboard”. Moreover, in situations where an individual might remain stationery for a relatively long time, for example, at a concert or sporting event, it is unrealistic to assume that an individual would keep their upper and lower extremities in such a constraining position. The BS8300 research did not report occupied widths larger than 800 mm but the BS8300 standard, as we interpret it, requires an additional 100 mm (4 in.) more than that for the clear floor area width (900 mm). The BS8300 standard’s developers may have added 100 mm to provide additional maneuvering room at clear floor areas.

Due to recent revisions, the minimum required clear floor width standard in Australia and the U.K. now exceeds that in U.S. and Canada (Figure 3‒3). The U.K. standard accommodates the occupied widths of most everyone in all of the studies, except for a small sample of the largest widths measured in our study. Approximately 90% of manual wheelchair users, 85% of scooter users and 80% of powered chair users in our sample had occupied widths that were less than the U.S. clear floor width standard. Therefore, 10‒20% of individuals measured in our study have an occupied width that is greater than the U.S. standard of 760 mm (30 in.).

* Indicates data plotted in the graph.

Figure 3-3. Clear floor width (occupied width): research findings versus the standards.

3.3.4 Clear Floor Length

The mean value of clear floor length for our study (1250 mm or 49 in.) is above the clear floor length provided in the U.S. standards (1220 mm or 48 in.). Australian and U.K. have also recently increased the clear floor length standards (Figure 3‒4). The U.K. requirements for clear floor length exceed the U.S. by 130 mm (5 in.). The results of our study and other anthropometric studies support larger lengths to accommodate the vast majority of occupied WhMD lengths. The largest occupied lengths reported in all the anthropometric studies exceed the current standards, even the U.K. BS8300 standard of 1350 mm (53 in.). However, the results show that the 95th percentile values of occupied length are between 1250 mm. (49 in.) and 1480 mm (58 in.).

The difference between the maximum length in the UDI and Seeger studies and the others is so great that they are probably due to the presence of unusually large people and/or devices, or measurement error. The maximum length (occupied) recorded in the UDI study, for example, was over 2000 mm (6 ft.- 8 in.)! In the case of Seeger et al.’s work, we know that most of the sample was recruited from institutions and many may have had extended foot-rests or reclined backs on their chairs. No information was provided in the reports to assess whether individuals in either study could be considered outliers. For example, since the other studies together included over 1200 individuals and no other study reported a device as long as 2000 mm (78 in.), such a large value is likely a measurement error or a very rare occurrence. In fact, by coincidence, we met an individual who served as an advisor and participant in the UDI research. She recalled that there was one individual who had a “trailer” attached to her wheelchair that carried ventilator equipment which would not be required anymore due to advances in technology.

* Indicates data plotted in the graph.

Figure 3-4. Clear floor length (occupied length): research findings versus the standards.

3.3.5 Seat Height

Height dimension standards for seats prescribed in the Australian, Canadian and U.S. standards were very similar (480 mm or 18.9 in., 480 mm or 18.9 in. and 485 mm or 19 in., respectively). The values in the current standards for seat height are below the means for people we measured and those in the UDI study (Figure 3‒5). This is probably due to the increasing use of positioning systems, thick cushions and the availability of a wider range of wheel sizes since the 1970’s.

Comparisons of research findings on the seat heights for power chairs and scooters showed that mean seat heights measured in the UDI study were comparable to seat heights for the power chairs and scooters of our study; however, the differences grew larger toward the higher percentiles. Further, our study findings also revealed that occupied seat heights for manual chairs were much lower than seat heights for power chairs and scooters.

The reference points used for measurement can yield quite different results for seat height. The height of the seat can be measured at the edge and at the middle, under the cushion, on top of the cushion, etc. Thus, specifying exactly how it is measured is important for comparing results. We computed the occupied seat height by measuring a point underneath an individual’s buttocks using an extension of the electromechanical probe that we slipped in from the side between the occupant and seat interface. Our results would be different compared to other measurements not made in a similar manner.

* indicates data plotted in the graph

Figure 3-5. Seat height: research findings versus the standards.

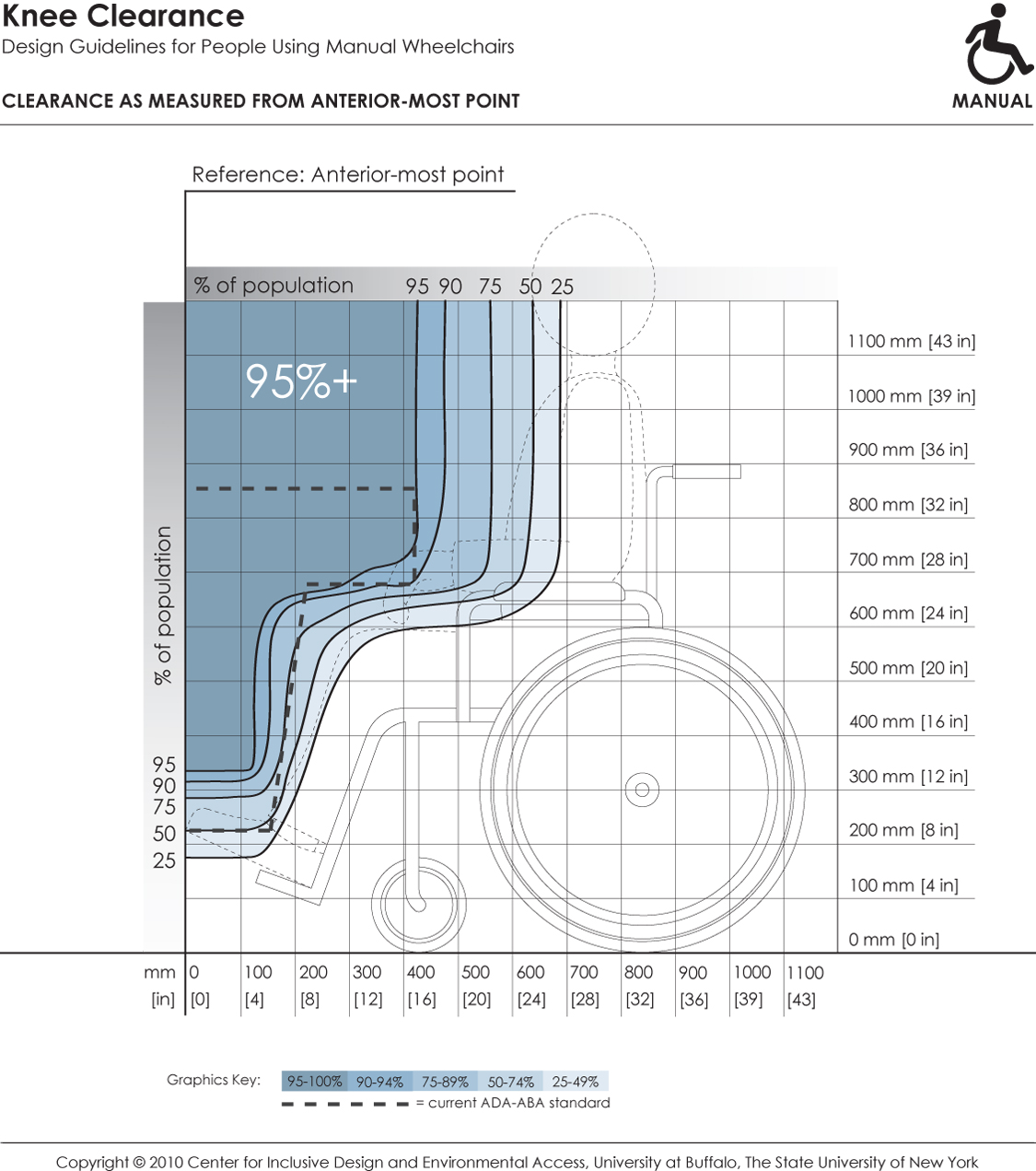

3.3.6 Knee Clearance Height, minimum

Knee clearance heights for the four sets of standards range from 650 mm (25.6 in.) (Australia) to 700 mm (27.6 in.) (U.K.) (Figure 3‒6). The U.S. standard for knee clearance height is 685 mm (27 in.). The U.K. BS8300 results for knee clearance height suggest that current U.K. standard generally accommodates most wheelchair users in that country. In the case of the U.S. and Canadian standards, however, the level of accommodation drops to 80% in relation to measured knee heights among wheelchair users in their respective countries.

A review of photographs of participants in the IDeA sample indicated that the largest individuals are not always the ones who need the greatest knee clearances. Smaller individuals who have large thighs, those with high seats and scooter users also have high lap heights. Individuals with extended footrests and scooter users have deep knee clearances but not necessarily high knee clearances.

* Indicates data plotted in the graph.

** Does not include individuals with an above-knee right leg amputation (n=6) or with the right leg constrained in fully extended position (n=3) such as in an orthopedic cast.

Figure 3-6. Knee clearance height: research findings versus the standards.

3.3.7 Toe Clearance Height, minimum

There is relatively large disparity between the standards for toe clearance height, with the U.S. having the lowest (230 mm or 9 in.), followed by Australia (280 mm or 11 in.) and the U.K. (300 mm or 12 in.) (Figure 3‒7). Our study suggests that the standards required in each of the countries, do not accommodate the vast majority of WhMD users, especially in the U.S. The mean toe height for the overall sample of WhMD users in our study was 230 mm (9 in.).

In particular, the 80th percentile of toe clearance height for manual chairs (276 mm or 10 in.) suggests that over 20% of manual chair users exceed the minimum required toe clearance height of 230 mm (9 in.). Corresponding clearance heights for power chair users were typically greater than manual chair users, and with over half the sample exceeding the minimum toe clearance height requirement.

* indicates data plotted in the graph

** does not include individuals with a below-knee right leg amputation (n=10) or with the right leg constrained in fully extended position (n=3) such as in an orthopedic cast

Figure 3-7. Toe clearance height: research findings versus the standards.

3.3.8 Knee Clearance Depth, minimum

Knee clearance depths for the four sets of standards range from 200 mm (8 in.) in Canada to 280 mm (11 in.) in the U.S. (Figure 3‒8). None of the comparison studies used for this report provided anthropometric information about knee clearance depth. The results of our study suggest that a large percentage of WhMD users are not accommodated by the standards. The U.S. standard on knee clearance depth accommodated just over 50% of our overall sample, and was well below the 80th percentile values of maximum knee height for manual wheelchair users (369 mm or 14.5 in.) and power chair users (345 mm or 13.5 in.). Even fewer would be accommodated by the standards of the U.K., Australia and Canada. A knee clearance depth of over 400 mm (16 in.) is needed to accommodate close to 95% of our sample’s manual and powered wheelchair users.

* indicates data plotted in the graph

** does not include individuals with an above-knee right leg amputation (n=7) or with the right leg constrained in fully extended position (n=3) such as in an orthopedic cast.

Figure 3-8. Knee clearance depth: research findings versus the standards

3.3.9 Toe Clearance Depth, minimum

Toe clearance depths for the standards range from 150 mm (6 in.) in the U.S. to 230 mm (9 in.) in Canada (Figure 3‒9). None of the comparison studies used for this report provided anthropometric information about toe clearance depth. While the Canadian standard accommodates over 85% of our WhMD users, the U.S. standard accommodates fewer than 50% of our sample.

* Indicates data plotted in the graph.

** Does not include individuals with a below-knee right leg amputation (n=10) or with the right leg constrained in fully extended position (n=3) such as in an orthopedic cast.

Figure 3-9. Toe clearance depth: research findings versus the standards.

3.3.10 90-Degree Turn

While all of the standards compared in this report have requirements for “wheelchair turning spaces”, only the U.S. and Canada have requirements specifically for 90-degree or L-Turn clearances. These are similar for both countries, 915 mm (36 in.) and 920 mm (36.2 in.) for the U.S. and Canada, respectively.

The width required for all participants to complete a 90-degree turn in our sample was much smaller than the UDI findings (Figure 3‒10), due to differences in the abilities of people or/and WhMD technologies included in each of the studies or due to the different measurement procedures employed.

An increase in the 90-degree turning width criterion from 915 mm (36 in.) to 1000 mm (39 in.) would accommodate at least 95% of our sample. It also appears that there are some manual chair, power chair and scooter users who require much larger spaces than the 95th percentile values.

* indicates data plotted in the graph

Figure 3-10. 90-degree turning width: research findings versus the standards.

3.3.11 180-Degree Turn

The mean width required for all participants to complete a 180-degree turn in our sample was smaller than the UDI findings (Figure 3‒10), but our 95th percentile values for power chair and scooters users were larger than the maximum values obtained in the UDI study. The disparities are likely due to the differences in the studies described previously.

The space requirements for a 180-degree turn are similar across countries, ranging from 1500 mm (59 in.) in the U.K. and Canada to 1540 mm (60.6 in.) in Australia. The U.S. standard of 1525 mm (60 in.) accommodates just over 80% of the manual and powered wheelchair users, but less than 50% of the scooter users in our sample. An increase in the 180-degree turning width of at least 175 mm (7 in.) would be needed to accommodate 95% of manual and powered wheelchair users and 90% of the scooter users. Again, there are some manual chair users, power chair users and scooter users who require much larger spaces than the 95th percentile values, exceeding 500 mm (almost 20 in.) beyond the current U.S. standards!

* indicates data plotted in the graph

Figure 3-11. 180-degree turning width: research findings versus the standards.

3.3.12 180-Degree Turn around a Barrier

The U.S. has requirements for a 180-degree turn around a barrier that makes the width of the turn-around space dependent on the width of the passageway. If the barrier is less than 1220 mm (48 in.) wide, the standard calls for a minimum passage width of 1065 mm (42 in.) and a minimum turn-around space depth of 1220 mm (48 in.). If the passageway is narrower, the turn-around depth must be 1525 mm. (60 in.).

Our study was the only one of those compared in this report to evaluate 180-degree turning performance around the barrier. The results show that the current standards accommodate at least 90% of the powered chair users and manual wheelchair users, and almost 80% of the scooter users in our sample. However, they also demonstrate that the depth of the turn-around space could be reduced if the passageway width is at least 1095 mm. (43 in.).

* indicates data plotted in the graph

Figure 3-12. 180-degree turning width around barrier: research findings versus the standards.

3.3.13 360-Degree Turn

The standards on the space requirements for a 360-degree turn are quite similar across countries, ranging from 1500 mm (59 in.) in Canada and the U.K. to 1525 mm (60 in.) in the U.S.

Less than 50% of our manual and powered wheelchair users completed a 360-degree turn within the United States standard turning diameter (Figure 3‒12). None of our sample’s scooter users were able to complete a turn within the U.S. standard. In fact, the tightest 360 turn performed by a scooter user was 1900 mm (75 in.) in diameter! The 360-degree turning diameter would have to be increased to 2500 mm (a little over 98 in.) to accommodate our entire study sample.