Ground and Floor Surfaces [4.5]

Scoping [4.1.2(4), 4.1.3(3)]

Requirements in 4.5 apply to accessible routes and spaces, including ramps, elevators, platform lifts, and clear floor space. These requirements apply to interior and exterior accessible routes and spaces.

General [4.5.1]

Many variables affect the performance of a given walking surface, including slope and cross slope, its material, jointing, texture, and finish, the presence of moisture or contaminants, the material that contacts it and the method of ambulation. Design guidelines cannot encompass all criteria contributing to the safety of a walking surface. ADAAG addresses surface material, texture, and finish and requires them to be "stable," "firm," and "slip-resistant." No standard or method of measurement exists for these characteristics except for slip-resistance.

A "stable" surface is one that is not permanently changed by ordinary contaminants or applied force so that when a contaminant or force is removed, the surface returns to its original condition under normal use. A "firm" surface is resistant to deformation by indentations or particles moving on or across it.

Slip-resistance is based on the frictional force necessary to keep a shoe heel or crutch tip from slipping on a walking surface under conditions likely to be found on the surface. The static coefficient of friction provides a close approximation of a surface's slip-resistance. ADAAG does not require compliance with a specified level of slip-resistance since the static coefficient of fiction, which can be measured in several ways, varies according to the measuring method used. (Recommended levels in the ADAAG appendix of 0.6 for level surfaces and 0.8 for ramps are advisory, not mandatory). Affected industries (floor finishes, ceramic tile, and plumbing fixtures) each employ a different testing method in designating the slip-resistance of their products. In the absence of any specified means of measuring slip-resistance, materials and products can be specified according to the values determined within the industry. ADAAG is not interpreted as prohibiting use of specific materials since texturing or other treatments may sufficiently enhance slip-resistance, though some alternatives, such as applied surfaces, will require greater maintenance (reapplication) than others. Recommendation: Slip-resistance should be specified according to the conditions likely to be found on the surface. Exterior routes and spaces that are not protected, lobbies and entrances, bathing facilities and other areas where floor surfaces are often wet, should have a higher level of slip-resistance.

Exterior Surfaces

Materials such as gravel, wood chips, or sand which are often used for outdoor walkways are neither firm or stable nor are they generally considered slip-resistant. However, some natural surfaces, such as compacted earth, soil treated with consolidants, or materials stabilized and retained by permanent or temporary geotextiles (mesh), gridforms, or similar construction may perform satisfactorily for persons using wheelchairs and walking aids.

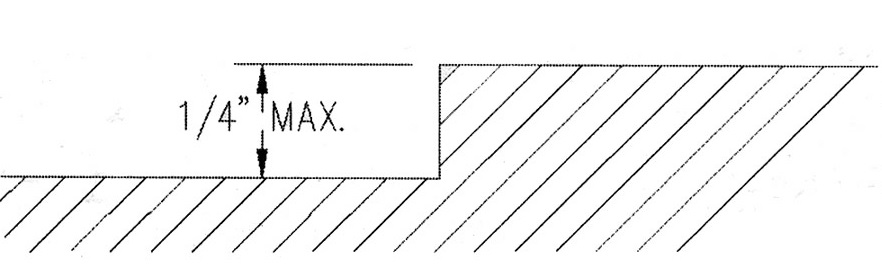

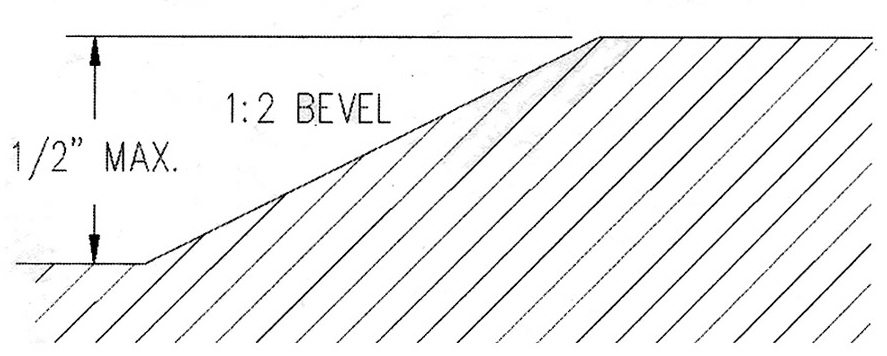

Changes in Level [4.5.2]

Vertical changes in level up to ¼ inch are permitted without treatment along accessible routes. Changes in level ¼ to ½ inch must be beveled with a slope no greater than 1:2. Changes in level greater than ½ inch where the slope is more than 5% must be treated as a curb ramp [4.7] or ramp [4.8].

Carpet [4.5.3]

Carpeting can significantly increase the amount of force needed to propel a wheelchair over a surface. Studies show that the level of roll resistance of carpet, even low-pile carpet that is properly secured, is considerably higher than the roll resistance of firmer surfaces such as concrete and linoleum. The firmer the carpeting (and backing), the lower the roll resistance. A pile thickness up to ½ inch (measured to the backing, cushion, or pad) is allowed, although a lower pile provides easier wheelchair maneuvering. If a backing, cushion or pad is used, it must be firm. Recommendation: Preferably, carpet pad should not be used because the soft padding increases roll resistance.

There should be minimum movement, none if possible, between the cushion or pad and the carpet. In high traffic areas, where this attachment may loosen or where a thick soft (plush) cushion or pad is used, wheelchair travel can become very difficult. Secure attachment to the floor is important to prevent buckling or warping. Trim is required along the full length of any exposed edges. This helps keep carpet from curling which can pose a tripping hazard and make wheelchair traffic difficult. The trim must meet requirements for changes in level.

Mats

Recommendation: ADAAG does not contain provisions for carpet that is not permanently fixed, such as matting placed in lobbies during inclement weather. Where used, it is recommended that they meet the pile height and trim requirements for fixed carpeting, have firm tapered edges for smooth transitions, be firm enough to minimize buckling or rolling and have an underside material or texture that grips the floor.

Gratings [4.5.4]

Gratings can pose a hazard by catching or entrapping the tips of crutches and walkers or narrow wheels of a wheelchair. The spacing between grates and orientation to the direction of travel can reduce these risks. ADAAG requires a maximum opening dimension of ½ inch in one direction and that elongated openings be placed so that the long dimension is perpendicular to the dominant direction of travel. These requirements apply to gratings located in any walking surface, including courtyards and plazas, not just those on accessible routes.

Recommendation: ADAAG does not specifically address other types of openings or gaps in ground or floor surfaces, such as those between pavers or at expansion joints. Irregular paved surfaces where joint surfaces may be recessed below the level, of the paving unit can disrupt wheelchair maneuvering even if the differences in level are less than ¼ inch. The ½ inch horizontal maximum specified for gratings is a good rule of thumb for these openings as well. Gaps or openings wider than ½ inch should be avoided or else treated, especially where they run parallel to a direction of travel.

User Comments/Questions

Add Comment/Question