Doors [4.13]

Scoping [4.1.3(7)]

Doors required to be accessible include:

-

at least one door at each accessible entrance

-

at least one door at each accessible space within a building or facility

-

each door that is an element of an accessible route or an accessible means of egress.

Clear Width [4.13.5] and Vertical Clearance

The clear width of the opening is measured from the face of the door in a 90 degrees open position to the opposite stop. Panic bars and other hardware do not require additional width since they are usually mounted above the widest portion of wheelchairs. In alterations, a projection up to 5/8 inch is permitted for the latch-side stop where it would otherwise be necessary to widen a door. Swing-away or offset hinges can provide additional clearance. Headroom at least 80 inches high is required along all circulation routes, including doorways. Eighty-inch doors, including those equipped with closers, are considered acceptable under this requirement.

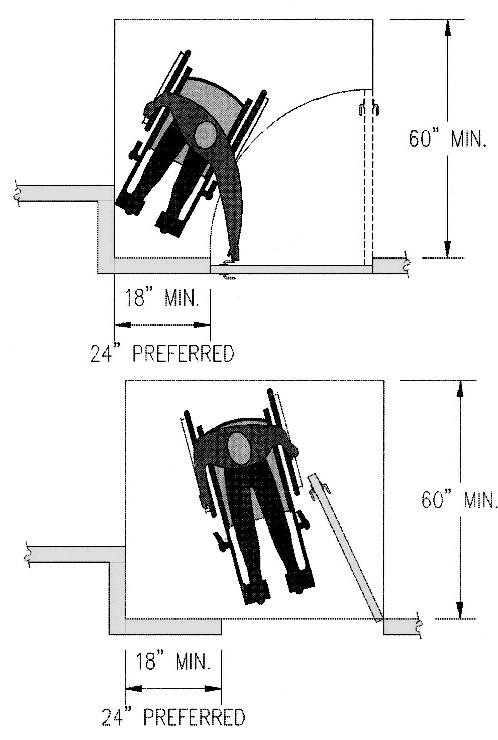

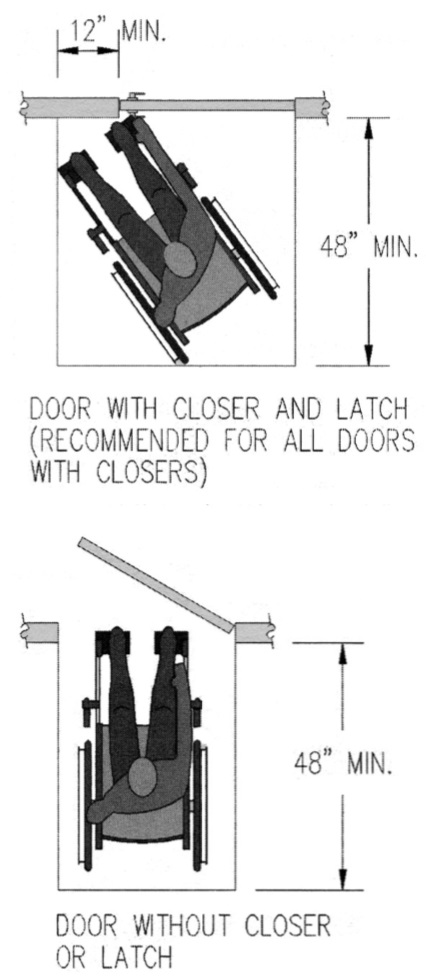

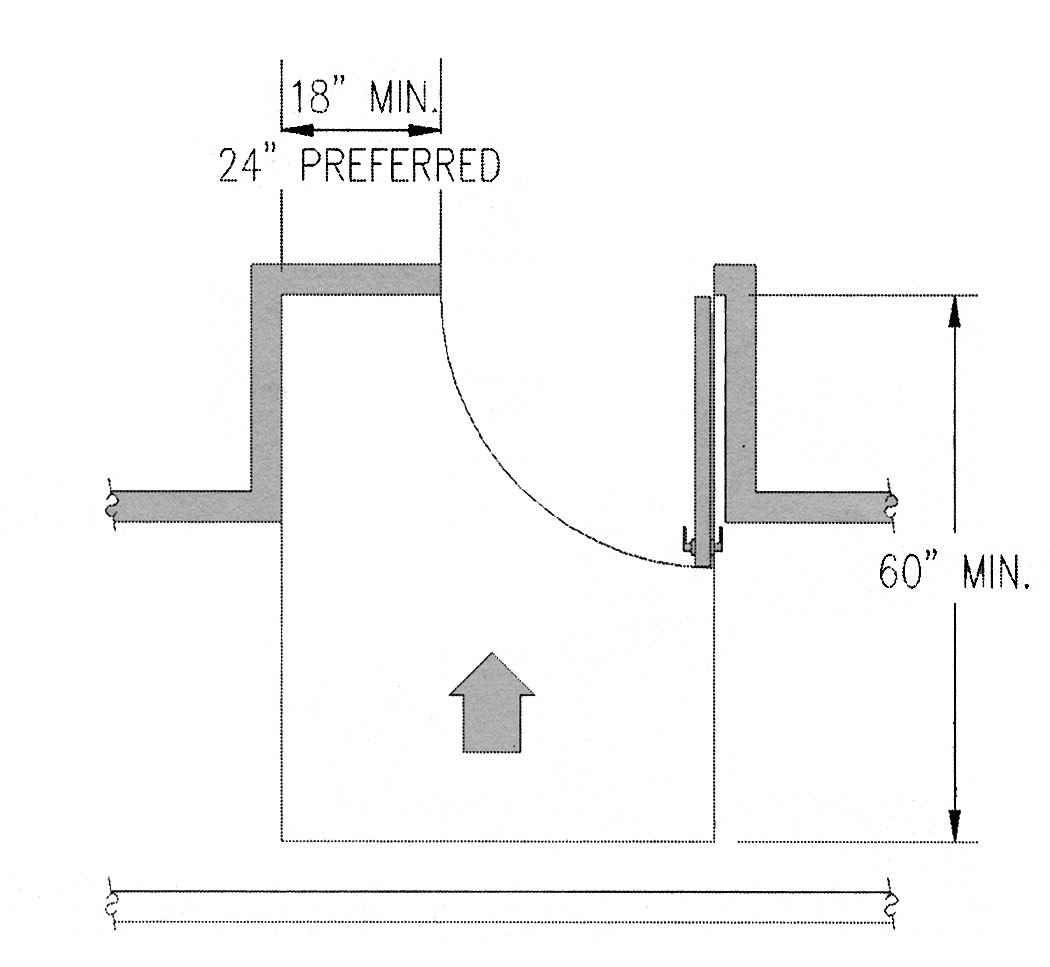

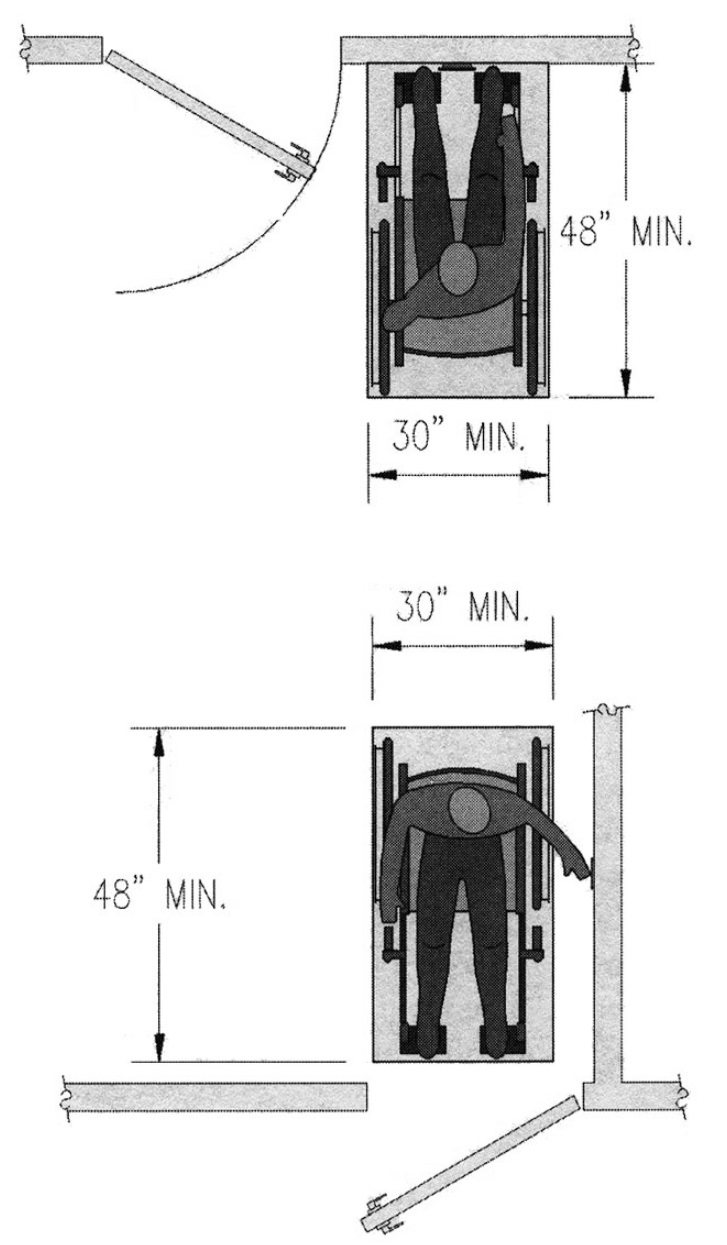

Maneuvering Clearances at Doors [4.13.6]

Pull-side clearance beyond the door swing provides space for a forward reach to door hardware. Maneuvering through doors is often done on an angle, particularly at doors with closers, and the minimum space required is also dependent on how the door may be approached.

Clearance to the wall plane next to the door (even when the door is in a recess) is essential. This maneuvering space is necessary for anyone using a wheelchair or crutches because the person cannot easily move or step back while opening the door. At what point a recess or the thickness of a wall becomes a problem is not clear. However, the clearance at thick walls must be in the plane of the face of the doorway (unless doors are automated). It is also important that wall-mounted elements, including those with knee and toe space, such as lavatories, not overlap this clearance due to the angled maneuvering necessary. However, limited projections, such as wall-mounted handrails are permitted to overlap clearances.

Latch-side clearance is needed on the push side to be able to operate a latch and maneuver through the door against the force of a closer. The minimum required push-side maneuvering space also is dependent on the approach direction.

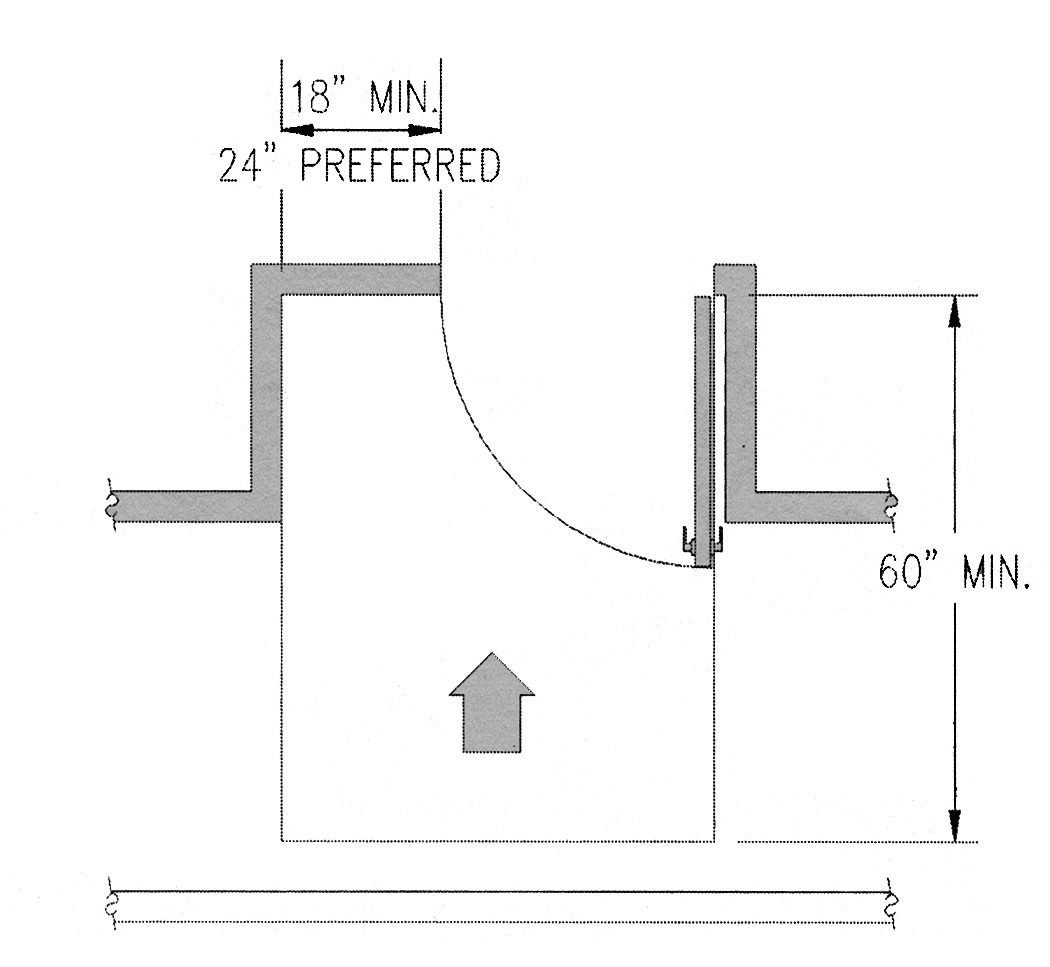

Forward approach clearances are required at doors located in alcoves.

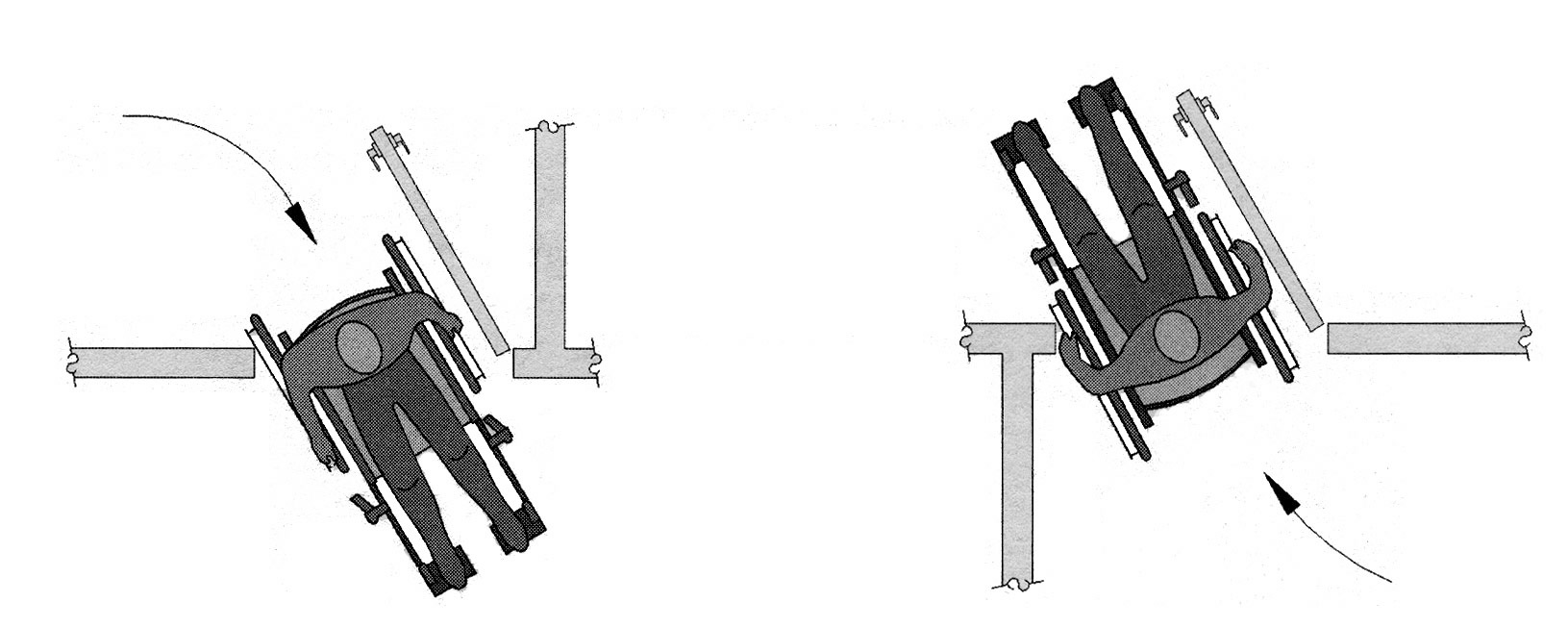

Clearances for Side Approaches

Clearance for side approaches are based on the swing of doors, direction of approach (hinge or latch), and the provision of closers (in some cases latches too). Generally, on the pull side, wheelchair maneuvering is easier from a latch side approach than from a hinge side approach; on the push side, maneuvering is easier from the hinge side than from the latch side.

These clearances, which are permitted to overlap, may determine the width of corridors, including entry alcoves with offset doors. Keep in mind that requirements for accessible routes in 4.3, including those for turns around obstructions, may apply as well.

Thresholds at Doorways [4.13.8]

Thresholds complicate wheelchair maneuvering through doors, especially at doors equipped with closers. Negotiating level changes while simultaneously resisting the force of closers can be difficult. Also, thresholds can be hard to cross on the diagonal as is often the situation encountered by a person using a wheelchair. ADAAG specifies a maximum threshold height of ½ inch, but allows a height up to ¾ inch at exterior sliding doors where necessary to prevent water damage. Thresholds above ¼ inch must be beveled with a slope no greater than 1:2.

Door Hardware [4.13.9]

Hardware used to operate doors, including handles, pulls, latches and locks, must have a shape that is "easy to grasp with one hand" and does not require tight grasping or pinching, or twisting of the wrist to operate (i.e., no round knobs). Various types of hardware are acceptable although those that can be operated with a closed fist (levers, push bars) or a loose grip (pull handles) accommodate the broadest range of users. Thumb turns, which are operated with simultaneous hand and finger movement, require a high degree of dexterity and coordination and are not recommended. When sliding doors are fully open, the hardware must be exposed and usable from both sides.

Locks and Security Devices

Permanently fixed portions of locks, including key locks, bolts, card readers, and push-button devices with number codes for general use by building occupants must comply with ADAAG specifications. (However, locks at store front gates and other security devices used only by employees in job-related tasks are not required to comply.) Keys, magnetic cards, and other devices not permanently fixed are not technically covered by ADAAG although they may need to be adapted for use by certain individuals as an accommodation. Locks activated by magnetic inserts, card swipes, or push-button pads are easier to use than turn-key locks as they require less grasping or twisting of the wrist to operate.

Kickplates

Recommendation: Some people with disabilities may use walkers or wheelchair footrests to push through doors, particularly those with closers. Applied kickplates can help protect the door surface. If provided, it is recommended that they cover almost the full door width up to a height of 16 inches from the bottom edge.

Door Closers [4.13.10]

Because it may be difficult for a person with a disability to open a door against the resistance offered by a closer, it is important that the closing action be slow enough to allow entry and exit. ADAAG requires that the sweep period of the closer be adjusted so that from an open position of 70 degrees, the door will take at least 3 seconds to move to a point 3 inches from the latch, measured to the leading edge of the door.

Measuring Opening Force

The maximum force pertains to the continuous application of force necessary to fully open a door, not the initial force needed to overcome the inertia of the door. It does not apply to the force required to retract bolts or to disengage other devices used to keep the door in a closed position. In measuring with a push-pull scale, force should be applied gradually so that the applied force does not exceed the resistance of the door. While there are instruments specifically designed for this purpose (e.g., tensionometer), a device as simple as a spring-loaded plunger or "fish" scale is effective in measuring the force required to open a door.

Exterior/ Fire Doors

A maximum opening force is not specified for exterior swing doors because the closing force required by building codes usually exceeds an "accessible" resistance. Factors that affect closing force are the weight of the door, wind and other exterior conditions, gasketing, air pressure, HVAC systems, energy conservation, etc. Research sponsored by the Board ("Automated Doors" by Adaptive Environments Laboratory (1993) indicates that a force of 15 lb is probably the most practicable as a specified maximum. Considering that closing force is 60% efficient, a 15 Ib maximum for opening force provides 9 lb for closure and latching, which may be sufficient for most doors. However, a 15 Ib opening force greatly exceeds the 5 Ib maximum considered suitable for people with disabilities. Providing automatic door openers may be the only practical alternative for ensuring the usability of exterior doors in many cases. Otherwise, the closing force should be set to the lowest level possible. To avoid any conflict with building or life safety codes, ADAAG requires fire doors to have the minimum opening force permitted by the appropriate administrative authority.

Automatic Doors and Power Assisted Doors [4.13.12]

Automated doors are classified by industry standards according to the level of force produced by the door opening. Fully automatic doors, which produce the most force, are usually activated through control mats or sensory devices and are often used in facilities with heavy traffic such as airport terminals and grocery stores where people may be traveling with luggage or shopping carts. Low-powered doors are typically used at entries with lower levels of traffic to provide an alternative to manual doors, including revolving doors, in the same location. Most operate slowly, allow manual opening, and are often activated by a push button or plate. Devices that can be reactivated before the closing cycle is completed are recommended where traffic may be high. Power-assisted doors facilitate door opening by reducing the resistance force of closers. Some power-assists are activated by opening the door manually (and must meet ADAAG requirements for maneuvering clearance in 4.13.6 and opening force in 4.13.11) while others may be activated by a switch.

Controls

Push buttons or plates and switches are subject to relevant requirements for controls and operating mechanisms, including the maximum 5 Ib operating force. Recommendations: Buttons and plates should be raised or flush and at least ¾ inch in diameter (as specified for elevator control panels). Consider push plates at least 3 inches in the least dimension since they do not require fine motor coordination or visual acuity to operate. Clear floor space at controls should be located outside the door swing.

Closers

Automated door closing is addressed by the ANSI/BHMA standards. In addition, ADAAG requires that low-energy doors not open to back check faster than 3 seconds and require no more than 15 Ib, which is consistent with ANSI/BHMA A156.19.

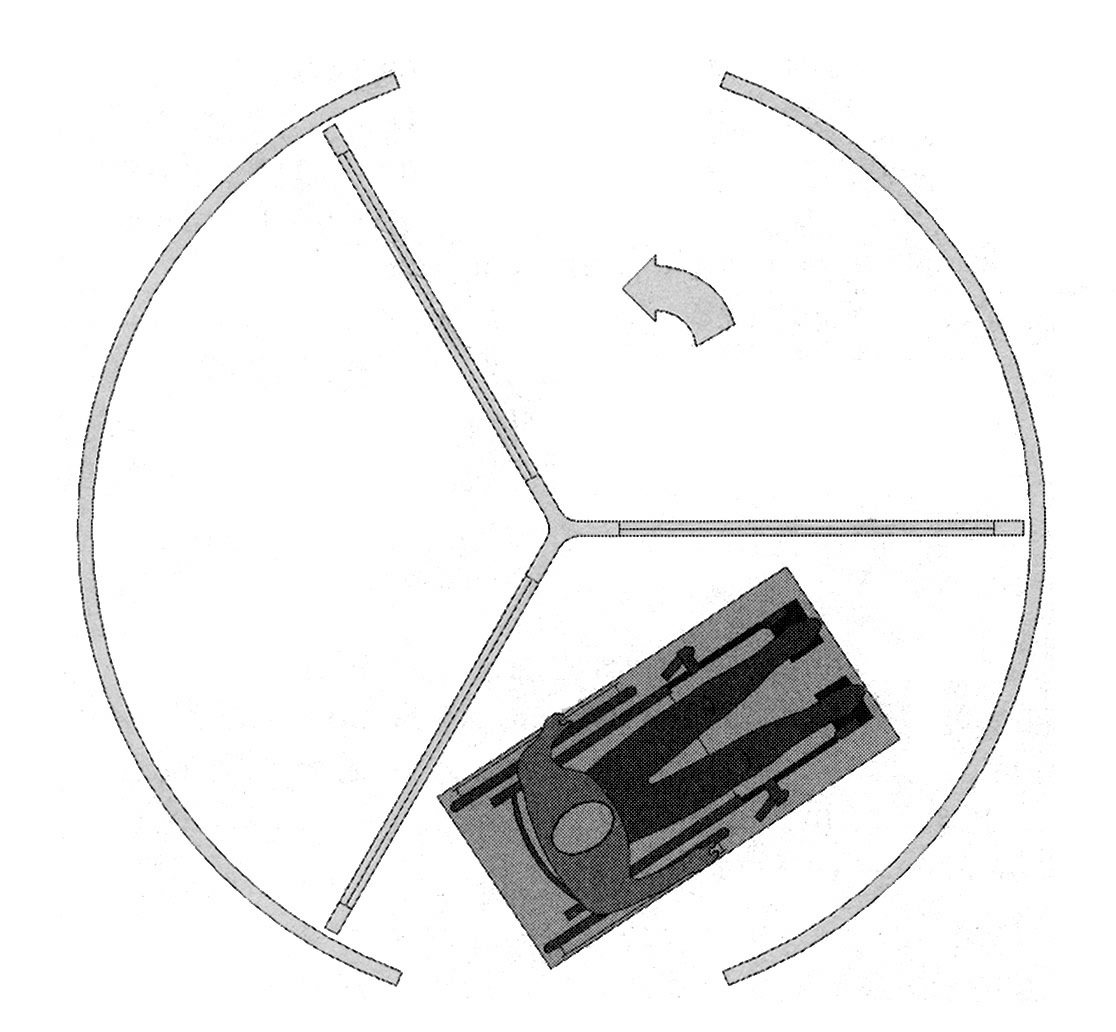

Automated Revolving Doors.

Automated Revolving Doors

Automated revolving doors, if large enough, may be usable by many people who use wheelchairs although ADAAG requires that a revolving door not be the only means of passage at an accessible entrance [4.13.2]. An alternate door in full compliance with 4.13 is considered necessary since some people with disabilities may be uncertain of their usability or may not move quickly enough to use them. (Life safety codes also usually require a secondary swing door). While manufacturers have developed safety criteria, the industry safety code for automated doors referenced by ADAAG does not currently address revolving doors, and certain questions remain, such as the appropriate maximum speed.

Research sponsored by the Board ("Automated Doors" by Adaptive Environments Laboratory (1993)) indicates that automated revolving doors, in order to be wheelchair accessible, must have a diameter of at least 10 to 12 feet depending on the number of compartments so that each compartment provides clear floor space at least 30 by 48 inches. Other recommendations from this study include:

-

a minimum 32 inch clearance for each leaf when hinged out for emergency use

-

safety systems such as motion detectors within compartments and at the door opening that stop door movement without contact

-

a slow mode (2 RPM) that can be activated automatically or by user activation (manufacturers have recommended a maximum speed of 4 RPM maximum for general use)

-

signage indicating slow down features and other user controls

User Comments/Questions

Add Comment/Question