2013 California Standards for Accessible Design Pocket Guide

11B-104 Conventions

11B-104.1 Dimensions.

Dimensions that are not stated as "maximum" or "minimum" are absolute.

11B-104.1.1 Construction and manufacturing tolerances.

All dimensions are subject to conventional industry tolerances except where the requirement is stated as a range with specific minimum and maximum end points.

[2010 ADAS] Advisory 104.1.1 Construction and Manufacturing Tolerances. Conventional industry tolerances recognized by this provision include those for field conditions and those that may be a necessary consequence of a particular manufacturing process. Recognized tolerances are not intended to apply to design work.

It is good practice when specifying dimensions to avoid specifying a tolerance where dimensions are absolute. For example, if this document requires "1½ inches," avoid specifying "1½ inches plus or minus X inches."

Where the requirement states a specified range, such as in 609.4 where grab bars must be installed between 33 inches and 36 inches above the floor, the range provides an adequate tolerance and therefore no tolerance outside of the range at either end point is permitted.

Where a requirement is a minimum or a maximum dimension that does not have two specific minimum and maximum end points, tolerances may apply. Where an element is to be installed at the minimum or maximum permitted dimension, such as "15 inches minimum" or "5 pounds maximum," it would not be good practice to specify "5 pounds (plus X pounds) or 15 inches (minus X inches)." Rather, it would be good practice to specify a dimension less than the required maximum (or more than the required minimum) by the amount of the expected field or manufacturing tolerance and not to state any tolerance in conjunction with the specified dimension.

Specifying dimensions in design in the manner described above will better ensure that facilities and elements accomplish the level of accessibility intended by these requirements. It will also more often produce an end result of strict and literal compliance with the stated requirements and eliminate enforcement difficulties and issues that might otherwise arise. Information on specific tolerances may be available from industry or trade organizations, code groups and building officials, and published references.

Conventional building industry tolerances include those for field conditions and those that may be a necessary consequence of a particular manufacturing process. Recognized tolerances are not intended to apply to design work.

Where accessibility provisions state a dimensional range, such as Section 11B-505.4 which requires the top of stair handrails to be installed between 34 inches and 38 inches above the nosing, the range already provides an adequate tolerance, therefore, no tolerance outside the range at either end point is permitted.

An element designed to be constructed at either the maximum or minimum permitted dimensions puts the construction at risk if construction errors result in a violation of the standards. It is good practice to specify a dimension less than the required maximum (or more than the required minimum) by the amount of the expected field or manufacturing tolerance and not to state any tolerance in conjunction with the specified dimension.

In other words, dimensions noted in accessibility provisions as “maximum” or “minimum” should not be considered dimensions for design, as they represent the limits of a requirement. To be sure that field tolerances result in usable construction, notes and dimensions in construction documents should anticipate expected tolerances so that a required dimensional range is not exceeded by the addition of a finish or a variation in construction practice.

Specifying dimensions in design in the manner described above will better ensure that facilities and elements accomplish the level of accessibility intended by the provision. It will also more often produce an end result of strict and literal compliance with the stated requirements and eliminate enforcement difficulties and issues that might otherwise arise. ◼

ETA Editor’s Note:

For additional information go to ADA Tolerances - Additional Resources or keyword search "Tolerance."

11B-104.2 Calculation of percentages.

Where the required number of elements or facilities to be provided is determined by calculations of ratios or percentages and remainders or fractions result, the next greater whole number of such elements or facilities shall be provided. Where the determination of the required size or dimension of an element or facility involves ratios or percentages, rounding down for values less than one half shall be permitted.

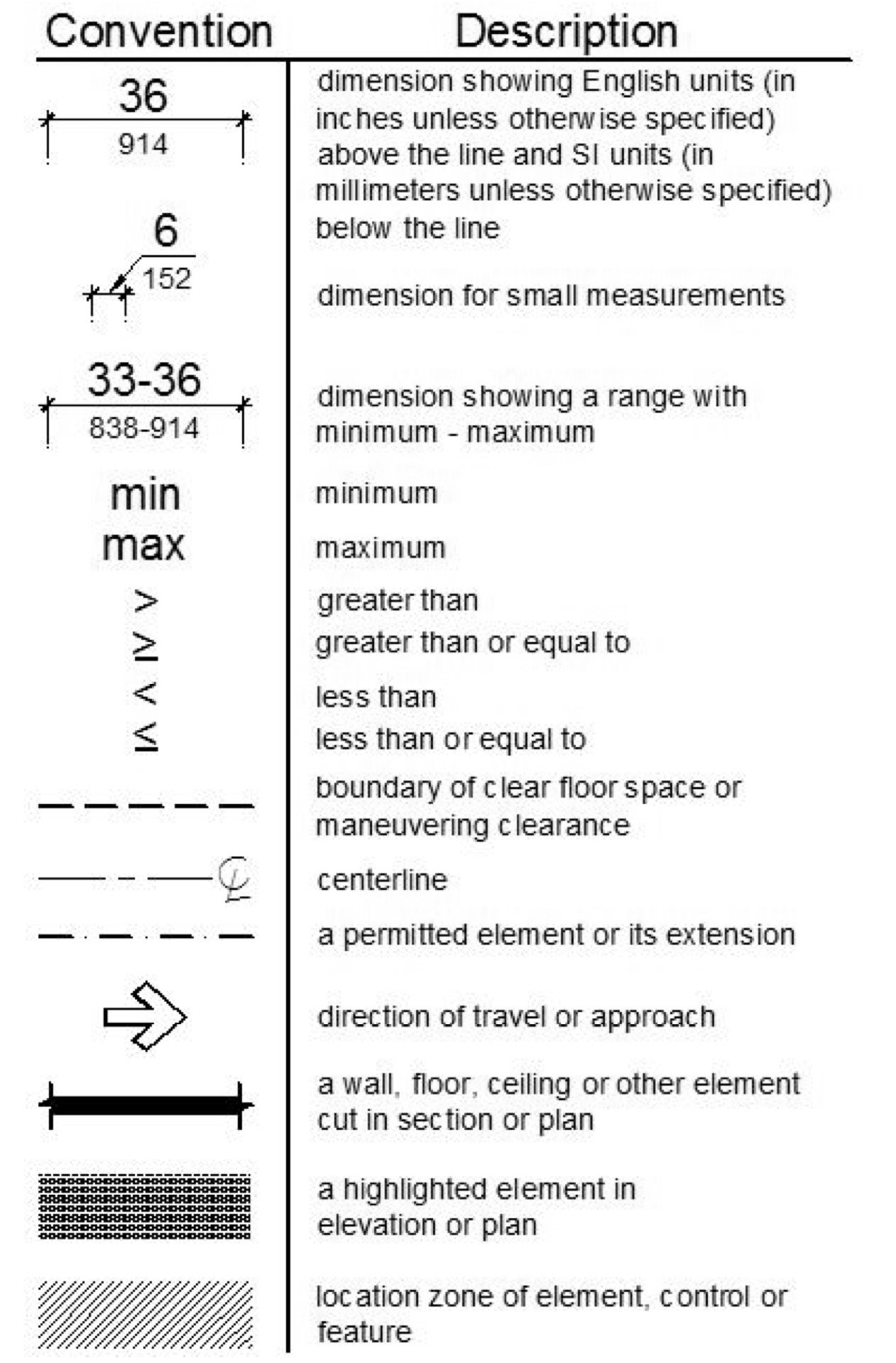

11B-104.3 Figures.

Unless specifically stated otherwise, figures are provided for informational purposes only.

FIGURE 11B-104

GRAPHIC CONVENTION FOR FIGURES

User Comments/Questions

Add Comment/Question