Subpart E—Commuter Rail Cars and Systems

(a) New, used and remanufactured commuter rail cars, to be considered accessible by regulations in part 37 of this title, shall comply with this subpart.

(b) If portions of the car are modified in such a way that it affects or could affect accessibility, each such portion shall comply, to the extent practicable, with the applicable provisions of this subpart. This provision does not require that inaccessible cars be retrofitted with lifts, ramps or other boarding devices.

(c)

(1) Commuter rail cars shall comply with §§38.93(d) and 38.109 of this part for level boarding unless structurally or operationally impracticable.

(2) Where level boarding is structurally or operationally impracticable, commuter rail cars shall comply §38.95 of this part.

(d) Existing vehicles retrofitted to comply with the “one-car-per-train rule” at §37.93 of this title shall comply with §§38.93(e), 38.95(a) and 38.107 of this part and shall have, in new and key stations at least one door on each side from which passengers board which complies with §38.93(d) of this part. Vehicles previously designed and manufactured in accordance with the program accessibility requirements of section 504 of the Rehabilitation Act of 1973, or implementing regulations of the Secretary of Transportation that were in effect before October 7, 1991; and which can be entered and used from stations in which they are to be operated, may be used to satisfy the requirements of §37.93 of this title.

(a) Clear width.

(1) At least one door on each side of the car from which passengers board opening onto station platforms and at least one adjacent doorway into the passenger coach compartment, if provided, shall have a minimum clear opening of 32 inches.

(2) If doorways connecting adjoining cars in a multi-car train are provided, and if such doorway is connected by an aisle with a minimum clear width of 30 inches to one or more spaces where wheelchair or mobility aid users can be accommodated, then such doorway shall have, to the maximum extent practicable in accordance with the regulations issued under the Federal Railroad Safety Act of 1970 (49 CFR parts 229 and 231), a clear opening of 30 inches.

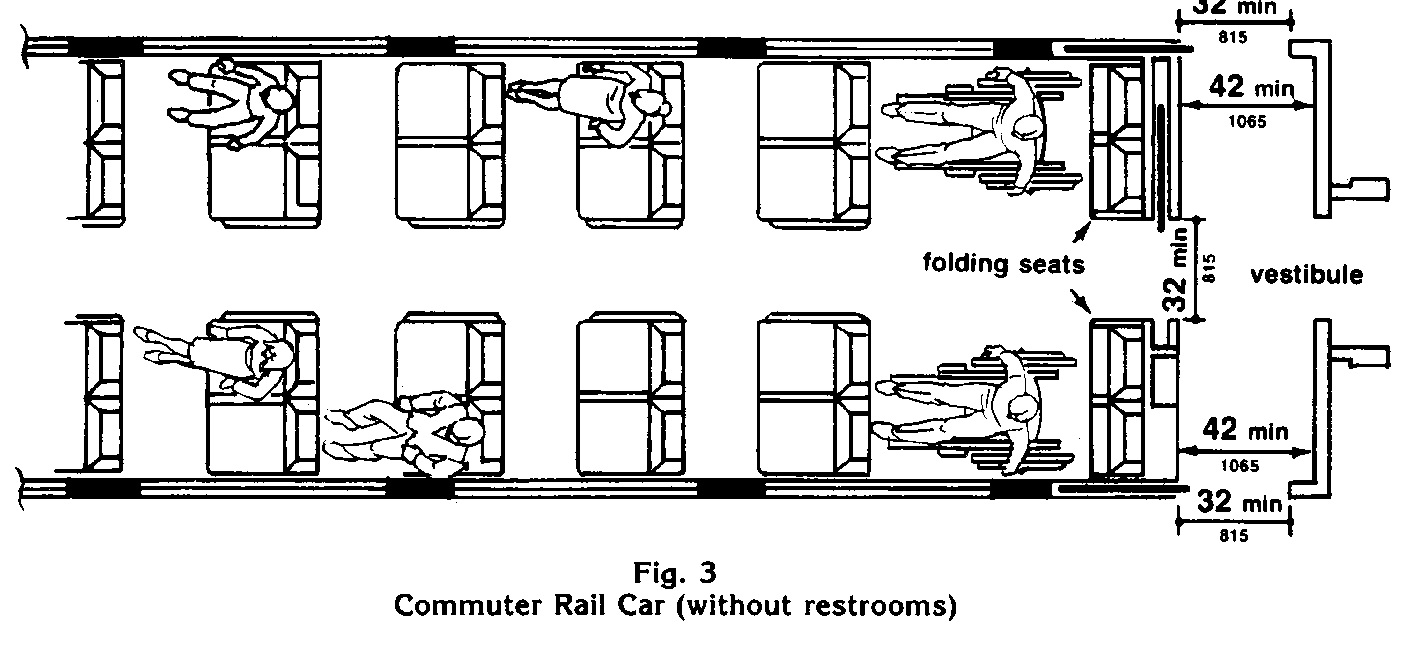

(b) Passageways. A route at least 32 inches wide shall be provided from doors required to be accessible by paragraph (a)(1) of this section to seating locations complying with §38.95(d) of this part. In cars where such doorways require passage through a vestibule, such vestibule shall have a minimum width of 42 inches. (See Fig. 3.)

(c) Signals. If doors to the platform close automatically or from a remote location, auditory and visual warning signals shall be provided to alert passengers or closing doors.

(d) Coordination with boarding platform—

(1) Requirements. Cars operating in stations with high platforms, or mini-high platforms, shall be coordinated with the boarding platform design such that the horizontal gap between a car at rest and the platform shall be no greater than 3 inches and the height of the car floor shall be within plus or minus 5/8 inch of the platform height. Vertical alignment may be accomplished by car air suspension, platform lifts or other devices, or any combination.

(2) Exception. New vehicles operating in existing stations may have a floor height within plus or minus 11/2 inches of the platform height. At key stations, the horizontal gap between at least one accessible door of each such vehicle and the platform shall be no greater than 3 inches.

(3) Exception. Where platform set-backs do not allow the horizontal gap or vertical alignment specified in paragraph (d)(1) or (d)(2) of this section, car, platform or portable lifts complying with §38.95(b) of this part, or car or platform ramps or bridge plates, complying with §38.95(c) of this part, shall be provided, ensuring compliance with section 37.42, where applicable.

(4) Exception. Retrofitted vehicles shall be coordinated with the platform in new and key stations such that the horizontal gap shall be no greater than 4 inches and the height of the vehicle floor, under 50% passenger load, shall be within plus or minus 2 inches of the platform height.

(e) Signage. The International Symbol of Accessibility shall be displaced on the exterior of all doors complying with this section unless all cars are accessible and are not marked by the access symbol (see Fig. 6). Appropriate signage shall also indicate which accessible doors are adjacent to an accessible restroom, if applicable.

(a)

(1) General. All new commuter rail cars, other than level entry cars, covered by this subpart shall provide a level-change mechanism or boarding device (e.g., lift, ramp or bridge plate) complying with either paragraph (b) or (c) of this section; sufficient clearances to permit a wheelchair or mobility aid user to reach a seating location; and at least two wheelchair or mobility aid seating locations complying with paragraph (d) of this section.

(2) Exception. If level-entry boarding, portable or platform lifts, ramps or bridge plates meeting the applicable requirements of this section are provided on station platforms or other stops required to be accessible, or mini-high platforms complying with §38.93(d) are provided, the car is not required to be equipped with a car-borne device. The access systems or devices used at a station to which section 37.42 applies must permit compliance with that section.

(b) Car Lift—

(1) Design load. The design load of the lift shall be at least 600 pounds. Working parts, such as cables, pulleys, and shafts, which can be expected to wear, and upon which the lift depends for support of the load, shall have a safety factor of at least six, based on the ultimate strength of the material. Nonworking parts, such as platform, frame, and attachment hardware which would not be expected to wear, shall have a safety factor of at least three, based on the ultimate strength of the material.

(2) Controls—

(i) Requirements. The controls shall be interlocked with the car brakes, propulsion system, or door, or shall provide other appropriate mechanisms or systems, to ensure that the car cannot be moved when the lift is not stowed and so the lift cannot be deployed unless the interlocks or systems are engaged. The lift shall deploy to all platform levels normally encountered in the operating environment. Where provided, each control for deploying, lowering, raising, and stowing the lift and lowering the roll-off barrier shall be of a monetary contact type requiring continuous manual pressure by the operator and shall not allow improper lift sequencing when the lift platform is occupied. The controls shall allow reversal of the lift operation sequence, such as raising or lowering a platform that is part way down, without allowing an occupied platform to fold or retract into the stowed position.

(ii) Exception. Where physical or safety constraints prevent the deployment at some stops of a lift having its long dimension perpendicular to the car axis, the transportation entity may specify a lift which is designed to deploy with its long dimension parallel to the car axis and which pivots into or out of the car while occupied (i.e., “rotary lift”). The requirements of paragraph (b)(2)(i) of this section prohibiting the lift from being stowed while occupied shall not apply to a lift design of this type if the stowed position is within the passenger compartment and the lift is intended to be stowed while occupied.

(iii) Exception. The brake or propulsion system interlock requirement does not apply to a platform mounted or portable lift provided that a mechanical, electrical or other system operates to ensure that cars do not move when the lift is in use.

(3) Emergency operation. The lift shall incorporate an emergency method of deploying, lowering to ground or platform level with a lift occupant, and raising and stowing the empty lift if the power to the lift fails. No emergency method, manual or otherwise, shall be capable of being operated in a manner that could be hazardous to the lift occupant or to the operator when operated according to manufacturer's instructions, and shall not permit the platform to be stowed or folded when occupied, unless the lift is a rotary lift intended to be stowed while occupied.

(4) Power or equipment failure. Platforms stowed in a vertical position, and deployed platforms when occupied, shall have provisions to prevent their deploying, falling, or folding any faster than 12 inches/second or their dropping of an occupant in the event of a single failure of any load carrying component.

(5) Platform barriers. The lift platform shall be equipped with barriers to prevent any of the wheels of a wheelchair or mobility aid from rolling off the lift during its operation. A movable barrier or inherent design feature shall prevent a wheelchair or mobility aid from rolling off the edge closest to the car until the lift is in its fully raised position. Each side of the lift platform which, in its raised position, extends beyond the car shall have a barrier a minimum 11/2 inches high. Such barriers shall not interfere with maneuvering into or out of the car. The loading-edge barrier (outer barrier) which functions as a loading ramp when the lift is at ground or station platform level, shall be sufficient when raised or closed, or a supplementary system shall be provided, to prevent a power wheelchair or mobility aid from riding over or defeating it. The outer barrier of the lift shall automatically rise or close, or a supplementary system shall automatically engage, and remain raised, closed, or engaged at all times that the lift platform is more than 3 inches above the station platform and the lift is occupied. Alternatively, a barrier or system may be raised, lowered, opened, closed, engaged or disengaged by the lift operator provided an interlock or inherent design feature prevents the lift from rising unless the barrier is raised or closed or the supplementary system is engaged.

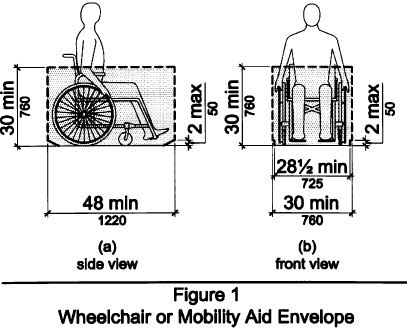

(6) Platform surface. The lift platform surface shall be free of any protrusions over 1/4 inch high and shall be slip resistant. The lift platform shall have a minimum clear width of 28 1/2 inches at the platform, a minimum clear width of 30 inches measured from 2 inches above the lift platform surface to 30 inches above the surface, and a minimum clear length of 48 inches measured from 2 inches above the surface of the platform to 30 inches above the surface. (See Fig. 1)

(7) Platform gaps. Any openings between the lift platform surface and the raised barriers shall not exceed 5/8 inch wide. When the lift is at car floor height with the inner barrier down (if applicable) or retracted, gaps between the forward lift platform edge and car floor shall not exceed 1/2 inch horizontally and 5/8 inch vertically.

(8) Platform entrance ramp. The entrance ramp, or loading-edge barrier used as a ramp, shall not exceed a slope of 1:8, when measured on level ground, for a maximum rise of 3 inches, and the transition from station platform to ramp may be vertical without edge treatment up to 1/4 inch. Thresholds between 1/4 inch and 1/2 inch high shall be beveled with a slope no greater than 1:2.

(9) Platform deflection. The lift platform (not including the entrance ramp) shall not deflect more than 3 degrees (exclusive of vehicle roll) in any direction between its unloaded position and its position when loaded with 600 pounds applied through a 26 inch by 26 inch test pallet at the centroid of the lift platform.

(10) Platform movement. No part of the platform shall move at a rate exceeding 6 inches/second during lowering and lifting an occupant, and shall not exceed 12 inches/second during deploying or stowing. This requirement does not apply to the deployment or stowage cycles of lifts that are manually deployed or stowed. The maximum platform horizontal and vertical acceleration when occupied shall be 0.3g.

(11) Boarding direction. The lift shall permit both inboard and outboard facing of wheelchairs and mobility aids.

(12) Use by standees. Lifts shall accommodate persons using walkers, crutches, canes or braces or who otherwise have difficulty using steps. The lift may be marked to indicate a preferred standing position.

(13) Handrails. Platforms on lifts shall be equipped with handrails, on two sides, which move in tandem with the lift which shall be graspable and provide support to standees throughout the entire lift operation. Handrails shall have a usable component at least 8 inches long with the lowest portion a minimum 30 inches above the platform and the highest portion a maximum 38 inches above the platform. The handrails shall be capable of withstanding a force of 100 pounds concentrated at any point on the handrail without permanent deformation of the rail or its supporting structure. The handrail shall have a cross-sectional diameter between 11/4 inches and 11/2 inches or shall provide an equivalent grasping surface, and have eased edges with corner radii of not less than 1/8 inch. Handrails shall be placed to provide a minimum 11/2 inches knuckle clearance from the nearest adjacent surface. Handrails shall not interfere with wheelchair or mobility aid maneuverability when entering or leaving the car.

(c) Car ramp or bridge plate—

(1) Design load. Ramps or bridge plates 30 inches or longer shall support a load of 600 pounds, placed at the centroid of the ramp or bridge plate distributed over an area of 26 inches by 26 inches, with a safety factor of at least 3 based on the ultimate strength of the material. Ramps or bridge plates shorter than 30 inches shall support a load of 300 pounds.

(2) Ramp surface. The ramp or bridge plate surface shall be continuous and slip resistant, shall not have protrusions from the surface greater than 1/4 inch high, shall have a clear width of 30 inches and shall accommodate both four-wheel and three-wheel mobility aids.

(3) Ramp threshold. The transition from station platform to the ramp or bridge plate and the transition from car floor to the ramp or bridge plate may be vertical without edge treatment up to 1/4 inch. Changes in level between 1/4 inch and 1/2 inch shall be beveled with a slope no greater than 1:2.

(4) Ramp barriers. Each side of the ramp or bridge plate shall have barriers at least 2 inches high to prevent mobility aid wheels from slipping off.

(5) Slope. Ramps or bridge plates shall have the least slope practicable. If the height of the vehicle floor, under 50% passenger load, from which the ramp is deployed is 3 inches or less above the station platform a maximum slope of 1:4 is permitted; if the height of the vehicle floor, under 50% passenger load, from which the ramp is deployed is 6 inches or less, but more than 3 inches, above the station platform a maximum slope of 1:6 is permitted; if the height of the vehicle floor, under 50% passenger load, from which the ramp is deployed is 9 inches or less, but more than 6 inches, above the station platform a maximum slope of 1:8 is permitted; if the height of the vehicle floor, under 50% passenger load, from which the ramp is deployed is greater than 9 inches above the station platform a slope of 1:12 shall be achieved. Folding or telescoping ramps are permitted provided they meet all structural requirements of this section.

(6) Attachment—.

(i) Requirement. When in use for boarding or alighting, the ramp or bridge plate shall be attached to the vehicle, or otherwise prevented from moving such that it is not subject to displacement when loading or unloading a heavy power mobility aid and that any gaps between vehicle and ramp or bridge plate, and station platform and ramp or bridge plate, shall not exceed 5/8 inch.

(ii) Exception. Ramps or bridge plates which are attached to, and deployed from, station platforms are permitted in lieu of car devices provided they meet the displacement requirements of paragraph (c)(6)(i) of this section.

(7) Stowage. A compartment, securement system, or other appropriate method shall be provided to ensure that stowed ramps or bridge plates, including portable ramps or bridge plates stowed in the passenger area, do not impinge on a passenger's wheelchair or mobility aid or pose any hazard to passengers in the event of a sudden stop.

(8) Handrails. If provided, handrails shall allow persons with disabilities to grasp them from outside the car while starting to board, and to continue to use them throughout the boarding process, and shall have the top between 30 inches and 38 inches above the ramp surface. The handrails shall be capable of withstanding a force of 100 pounds concentrated at any point on the handrail without permanent deformation of the rail or its supporting structure. The handrail shall have a cross-sectional diameter between 11/4 inches and 11/2 inches or shall provide an equivalent grasping surface, and have eased edges with corner radii of not less than 1/8 inch. Handrails shall not interfere with wheelchair or mobility aid maneuverability when entering or leaving the car.

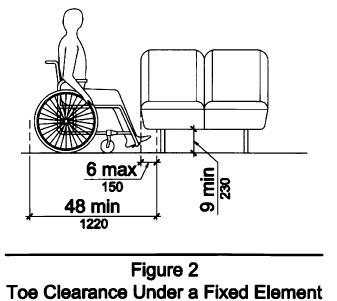

(d) Mobility aid seating location. Spaces for persons who wish to remain in their wheelchairs or mobility aids shall have a minimum clear floor space 48 inches by 30 inches. Such spaces shall adjoin, and may overlap, an accessible path. Not more than 6 inches of the required clear floor space may be accommodated for footrests under another seat provided there is a minimum of 9 inches from the floor to the lowest part of the seat overhanging the space. Seating spaces may have fold-down or removable seats to accommodate other passengers when a wheelchair or mobility aid user is not occupying the area, provided the seats, when folded up, do not obstruct the clear floor space required. (See Fig. 2.)

(a) Where provided, handrails or stanchions within the passenger compartment shall be placed to permit sufficient turning and maneuvering space for wheelchairs and other mobility aids to reach a seating location, complying with §38.95(d) of this part, from an accessible entrance. The diameter or width of the gripping surface of interior handrails and stanchions shall be 11/4 inches to 11/2 inches or shall provide an equivalent gripping surface. Handrails shall be placed to provide a minimum 11/2 inches knuckle clearance from the nearest adjacent surface.

(b) Where provided, handrails or stanchions shall be sufficient to permit safe boarding, on-board circulation, seating and standing assistance, and alighting by persons with disabilities.

(c) At entrances equipped with steps, handrails or stanchions shall be provided in the entrance to the car in a configuration which allows passengers to grasp such assists from outside the car while starting to board, and to continue using such assists throughout the boarding process, to the extent permitted by part 231 of this title.

(a) Floor surfaces on aisles, step treads, places for standees, and areas where wheelchair and mobility aid users are to be accommodated shall be slip-resistant

(b) All thresholds and step edges shall have a band of color(s) running the full width of the step or threshold which contrasts from the step tread and riser or adjacent floor, either light-on-dark or dark-on-light.

(a) Any stepwell or doorway with a lift, ramp or bridge plate shall have, when the door is open, at least 2 footcandles of illumination measured on the step tread, ramp, bridge plate, or lift platform.

(b) The doorways of cars not operating at lighted station platforms shall have outside lights which, when the door is open, provide at least 1 footcandle of illumination on the station platform surface for a distance of 3 feet perpendicular to all points on the bottom step tread edge. Such lights shall be shielded to protect the eyes of entering and exiting passengers.

(a) Each car shall be equipped with an interior public address system permitting transportation system personnel, or recorded or digitized human speech messages, to announce stations and provide other passenger information. Alternative systems or devices which provide equivalent access are also permitted.

(b) [Reserved]

(a) Each car shall contain sign(s) which indicate that certain seats are priority seats for persons with disabilities and that other passengers should make such seats available to those who wish to use them.

(b) Characters on signs required by paragraph (a) shall have a width-to-height ratio between 3:5 and 1:1 and a stroke width-to-height ratio between 1:5 and 1:10, with a minimum character height (using an upper case “X”) of 5/8 inch, with “wide” spacing (generally, the space between letters shall be 1/16 the height of upper case letters), and shall contrast with the background either light-on-dark or dark-on-light.

(a) If a restroom is provided for the general public, it shall be designed so as to allow a person using a wheelchair or mobility aid to enter and use such restroom as specified in paragraphs (a)(1) through (5) of this section.

(1) The minimum clear floor area shall be 35 inches by 60 inches. Permanently installed fixtures may overlap this area a maximum of 6 inches, if the lowest portion of the fixture is a minimum of 9 inches above the floor, and may overlap a maximum of 19 inches, if the lowest portion of the fixture is a minimum of 29 inches above the floor, provided such fixtures do not interfere with access to the water closet. Fold-down or retractable seats or shelves may overlap the clear floor space at a lower height provided they can be easily folded up or moved out of the way.

(2) The height of the water closet shall be 17 inches to 19 inches measured to the top of the toilet seat. Seats shall not be sprung to return to a lifted position.

(3) A grab bar at least 24 inches long shall be mounted behind the water closet, and a horizontal grab bar at least 40 inches long shall be mounted on at least one side wall, with one end not more than 12 inches from the back wall, at a height between 33 inches and 36 inches above the floor.

(4) Faucets and flush controls shall be operable with one hand and shall not require tight grasping, pinching, or twisting of the wrist. The force required to activate controls shall be no greater than 5 lbf (22.2 N). Controls for flush valves shall be mounted no more than 44 inches above the floor.

(5) Doorways on the end of the enclosure, opposite the water closet, shall have a minimum clear opening width of 32 inches. Doorways on the side wall shall have a minimum clear opening width of 39 inches. Door latches and hardware shall be operable with one hand and shall not require tight grasping, pinching, or twisting of the wrist.

(b) Restrooms required to be accessible shall be in close proximity to at least one seating location for persons using mobility aids and shall be connected to such a space by an unobstructed path having a minimum width of 32 inches.

§ 38.109 Between-car barriers.

Where vehicles operate in a high-platform, level-boarding mode, and where between-car bellows are not provided, devices or systems shall be provided to prevent, deter or warn individuals from inadvertently stepping off the platform between cars. Appropriate devices include, but are not limited to, pantograph gates, chains, motion detectors or other suitable devices.

User Comments/Questions

Add Comment/Question