(b) Vehicle lift—

(1) Design load. The design load of the lift shall be at least 600 pounds (2665 N). Working parts, such as cables, pulleys, and shafts, which can be expected to wear, and upon which the lift depends for support of the load, shall have a safety factor of at least six, based on the ultimate strength of the material. Nonworking parts, such as platform, frame and attachment hardware which would not be expected to wear, shall have a safety factor of at least three, based on the ultimate strength of the material.

(2) Controls—

(i) Requirements. The controls shall be interlocked with the vehicle brakes, transmission, or door, or shall provide other appropriate mechanisms or systems, to ensure that the vehicle cannot be moved when the lift is not stowed and so the lift cannot be deployed unless the interlocks or systems are engaged. The lift shall deploy to all levels (i.e., ground, curb, and intermediate positions) normally encountered in the operating environment. Where provided, each control for deploying, lowering, raising, and stowing the lift and lowering the roll-off barrier shall be of a momentary contact type requiring continuous manual pressure by the operator and shall not allow improper lift sequencing when the lift platform is occupied. The controls shall allow reversal of the lift operation sequence, such as raising or lowering a platform that is part way down, without allowing an occupied platform to fold or retract into the stowed position.

(ii) Exception. Where the lift is designed to deploy with its long dimension parallel to the vehicle axis and which pivots into or out of the vehicle while occupied (i.e., “rotary lift”), the requirements of this paragraph (b)(2) prohibiting the lift from being stowed while occupied shall not apply if the stowed position is within the passenger compartment and the lift is intended to be stowed while occupied.

(3) Emergency operation. The lift shall incorporate an emergency method of deploying, lowering to ground level with a lift occupant, and raising and stowing the empty lift if the power to the lift fails. No emergency method, manual or otherwise, shall be capable of being operated in a manner that could be hazardous to the lift occupant or to the operator when operated according to manufacturer's instructions, and shall not permit the platform to be stowed or folded when occupied, unless the lift is a rotary lift and is intended to be stowed while occupied.

(4) Power or equipment failure. Platforms stowed in a vertical position, and deployed platforms when occupied, shall have provisions to prevent their deploying, falling, or folding any faster than 12 inches/second (305 mm/sec) or their dropping of an occupant in the event of a single failure of any load carrying component.

(5) Platform barriers. The lift platform shall be equipped with barriers to prevent any of the wheels of a wheelchair or mobility aid from rolling off the platform during its operation. A movable barrier or inherent design feature shall prevent a wheelchair or mobility aid from rolling off the edge closest to the vehicle until the platform is in its fully raised position. Each side of the lift platform which extends beyond the vehicle in its raised position shall have a barrier a minimum 11/2 inches (13 mm) high. Such barriers shall not interfere with maneuvering into or out of the aisle. The loading-edge barrier (outer barrier) which functions as a loading ramp when the lift is at ground level, shall be sufficient when raised or closed, or a supplementary system shall be provided, to prevent a power wheelchair or mobility aid from riding over or defeating it. The outer barrier of the lift shall automatically raise or close, or a supplementary system shall automatically engage, and remain raised, closed, or engaged at all times that the platform is more than 3 inches (75 mm) above the roadway or sidewalk and the platform is occupied. Alternatively, a barrier or system may be raised, lowered, opened, closed, engaged, or disengaged by the lift operator, provided an interlock or inherent design feature prevents the lift from rising unless the barrier is raised or closed or the supplementary system is engaged.

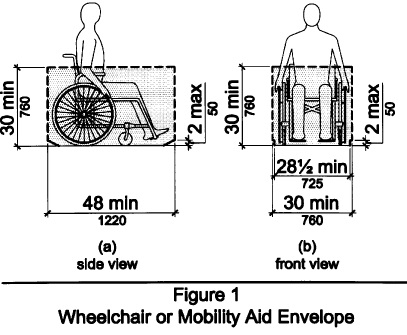

(6) Platform surface. The platform surface shall be free of any protrusions of 1/4 inch (6.5 mm) high and shall be slip resistant. The platform shall have a minimum clear width of 28 1/2 inches (725 mm) at the platform, a minimum clear width of 30 inches (760 mm) measured from 2 inches (50 mm) above the platform surface to 30 inches (760 mm) above the platform, and a minimum clear length of 48 inches (1220 mm) measured from 2 inches (50 mm) above the surface of the platform to 30 inches (760 mm) above the surface of the platform. (See Figure 1 to this part.)

(7) Platform gaps. Any openings between the platform surface and the raised barriers shall not exceed 5/8 inch (16 mm) in width. When the platform is at vehicle floor height with the inner barrier (if applicable) down or retracted, gaps between the forward lift platform edge and the vehicle floor shall not exceed 1/2 inch (13 mm) horizontally and 5/8 inch (16 mm) vertically. Platforms on semi-automatic lifts may have a hand hold not exceeding 11/2 inches (28 mm) by 41/2 inches (113 mm) located between the edge barriers.

(8) Platform entrance ramp. The entrance ramp, or loading-edge barrier used as a ramp, shall not exceed a slope of 1:8, measured on level ground, for a maximum rise of 3 inches (75 mm), and the transition from roadway or sidewalk to ramp may be vertical without edge treatment up to 1/4 inch (6.5 mm) . Thresholds between 1/4 inch (6.5 mm) and 1/2 inch (13 mm) high shall be beveled with a slope no greater than 1:2.

(9) Platform deflection. The lift platform (not including the entrance ramp) shall not deflect more than 3 degrees (exclusive of vehicle roll or pitch) in any direction between its unloaded position and its position when loaded with 600 pounds (2665 N) applied through a 26 inch (660 mm) by 26 inch test pallet at the centroid of the platform.

(10) Platform movement. No part of the platform shall move at a rate exceeding 6 inches/second (150 mm/sec) during lowering and lifting an occupant, and shall not exceed 12 inches/second (300 mm/sec) during deploying or stowing. This requirement does not apply to the deployment or stowage cycles of lifts that are manually deployed or stowed. The maximum platform horizontal and vertical acceleration when occupied shall be 0.3g.

(11) Boarding direction. The lift shall permit both inboard and outboard facing of wheelchair and mobility aid users.

(12) Use by standees. Lifts shall accommodate persons using walkers, crutches, canes or braces or who otherwise have difficulty using steps. The platform may be marked to indicate a preferred standing position.

(13) Handrails. Platforms on lifts shall be equipped with handrails on two sides, which move in tandem with the lift, and which shall be graspable and provide support to standees throughout the entire lift operation. Handrails shall have a usable component at least 8 inches (200 mm) long with the lowest portion a minimum 30 inches (760 mm) above the platform and the highest portion a maximum 38 inches (965 mm) above the platform. The handrails shall be capable of withstanding a force of 100 pounds (445 N) concentrated at any point on the handrail without permanent deformation of the rail or its supporting structure. The handrail shall have a cross-sectional diameter between 11/4 inches (32 mm) and 11/2 inches (38 mm) or shall provide an equivalent grasping surface, and have eased edges with corner radii of not less than 5/8 inch (3.5 mm). Handrails shall be placed to provide a minimum 11/2 inches (38 mm) knuckle clearance from the nearest adjacent surface. Handrails shall not interfere with wheelchair or mobility aid maneuverability when entering or leaving the vehicle.

User Comments/Questions

Add Comment/Question